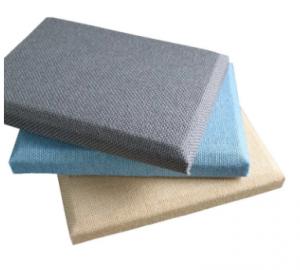

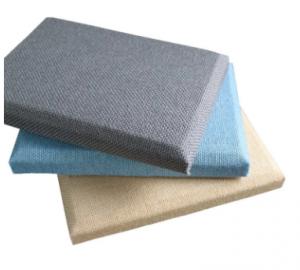

Fiberglass Wall Panel with Fabric HC-382

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 25mm, 40mm, 75mm and etc.

Size: Standard 1200*600mm, max 2700*1200mm and etc.

Surface: Decorative or Fiberglass Fabrics in different colors

Edge: Square, Bevel

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The first floor said yes. I feel it In the use of grid cloth at the same time you have to look at the quality of grid cloth.

- Q: How to do with glass fiber wall anti-crack

- First look at what is the wall, is the load-bearing walls, non-load-bearing walls, as well as the original wall is now there are cracks? Do the best way to do anti-crack wall is to shovel the original wall shovel, a plaster leveling or low-level gypsum leveling, after drying in the use of ecological white latex patch, cloth to use really good, so you can prevent the wall The surface is cracked.

- Q: What is the quality of the light barrier now?

- The partition board includes glass fiber reinforced concrete slab, glass fiber reinforced gypsum hollow slab, steel wire (steel mesh) reinforced concrete slab, light concrete slab, composite sandwich light bar and so on. The full name is the building wall with a light strip, as a general industrial buildings, residential buildings, public works of non-load-bearing wall of the main material. It is a lightweight partition project which is a non-bearing internal wall of a commercial building, a residential building and a public building project with a light partition.

- Q: FRP can be used to make walls

- If the use of fiberglass do wall to see and what it is connected to the medium, or very easy to stratify, if it is in the cement surface to do the wall, I suggest you use epoxy resin, resin and sub-reinforced resin and food Grade resin, with food grade resin to do, no harm to the body, that is not food-grade, after curing the harm to the human body than other decorative materials damage small

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- GRC reinforced cement board: glass fiber reinforced cement board, glass fiber is used as a reinforcing material, plus cement, sand, water, admixture and other materials made of slats, which apply to ordinary or mid-range building grade. Glass fiber reinforced concrete (GRC-Glass Fiber Reinforced Cement) is a new type of composite material.

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The current state to promote the third generation of environmentally friendly energy-saving partition board, with moisture, earthquake noise, fire insulation, small footprint, good strength, fast construction and other advantages.

- Q: What is GRC and can I paint it?

- GRC is the abbreviation of Glass Fiber Reinforced Cement, which is a new type of composite material invented in the 1970s. It is made of alkali-resistant glass fiber as reinforcing material, sulphoaluminate low basicity cement as cemented material and mixed with suitable aggregate Substrate, by jetting. Mold casting. Squeeze out. Flow pulp and other processes made of new inorganic composite materials. The It combines light, high strength, high toughness and water resistance, non-combustion, sound insulation, heat insulation, corrosion resistance, easy processing and other characteristics set in one, occupies a unique position in the building. In recent years, China's GRC technology to a new stage of development. The GRC technology can produce Roman column, eaves line, waist line, door cover, window cover, top set, window side column, light partition board, transformer Such as flue, railing, garden relief, Tibetan components, antique components, mountain flowers, corridor, cultural stone and other hundreds of varieties, smooth and exquisite appearance of the components, pattern smooth realistic, stereotypes perfect, strong sense of art. The following are the same as the " 2, construction, easy installation, short duration. Production of various GRC prefabricated components, with cement affinity. Nine blogs J o? ~?] 5Z?]?]? L 3, GRC components light weight, high strength, good toughness, no cracking, no layer, water, non-combustible, and housing with the life. Spray on the paint, with the stone fought. 4, no "waste" pollution, is conducive to environmental protection. 5, loss. If there is a small amount of damage in the transport can also be installed after the completion of the decoration with cement, to ensure that the utilization of components 100%.

- Q: Wall material that kind of environmental protection?

- Diatom mud soft bag wallpaper floor wall is now a lot of latex paint is also very environmentally friendly

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production process of glass fiber generally includes: raw material procurement, according to the formula for mixing, and then transported to the glass furnace for melting, clarification, through the operating channel flow to the drawing board, sizing agent after drawing through the drawing machine to form the original wire (Usually with yarn, weaving, chopping, puffing, twisting, etc.) or for sale (direct yarn)

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- If the insulation from the good, corrosion-resistant aspects to consider, then the inorganic glass fiber reinforced plastic composite panel better, for the following reasons: Inorganic glass fiber reinforced high temperature. (Under normal circumstances, the temperature of 400 degrees Celsius to keep the product is not deformed). Inorganic glass steel anti-aging, 20 years the product is not deformed. Clean air, can absorb air of carbon dioxide. high strength. Good waterproof performance. Light weight, second only to plexiglass steel. Low cost, low price of raw materials floating. Insulation, sound absorption. Not burning After disposal, it can be used for landfill. It is an ideal environmental protection material for water, soil and air.

Send your message to us

Fiberglass Wall Panel with Fabric HC-382

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords