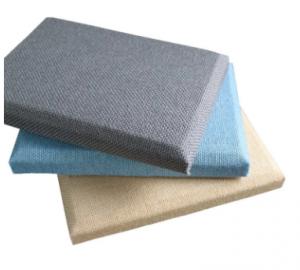

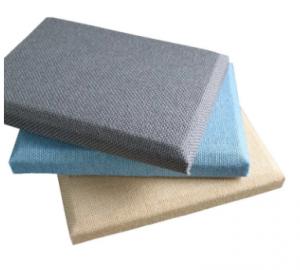

Fiberglass Wall Panel with Fabric HC-387

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 25mm, 40mm, 75mm and etc.

Size: Standard 1200*600mm, max 2700*1200mm and etc.

Surface: Decorative or Fiberglass Fabrics in different colors

Edge: Square, Bevel

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

- Q:Glass fiber mesh quality soft and hard for the wall, which is better?

- The softness of the mesh cloth does not depend on the quality of the mesh cloth. Depending on how much glue is applied. Used in the wall, of course, is a lot of glue, and can increase the degree of alkali resistance. Now there is a kind of urine glue, painted out really hard But this is not alkaline.

- Q:What is the difference between an ordinary partition board and a lightweight partition board?

- Light wall is a new type of energy-saving wall information, it is a kind of appearance like a hollow floor of the same wall material, but it has two male and female Falcon trough, the device only need to stand up, On a small number of mortar mortar after the assembly can be. It is composed of harmless phosphogypsum, light steel slag, fly ash and other industrial waste residue, by the frequency of steam pressure maintenance. Light wall panels with light weight, high strength, multiple environmental protection, thermal insulation, noise, breathing humidity, fire, rapid construction, down the cost of the wall and other advantages. The inner wall is equipped with reasonable layout of the insulation, sound absorption of inorganic foam profiles or other insulation materials, wall panels by the pipeline pouring, leveling, scientific maintenance, production of high degree of automation, the standard type.

- Q:The difference between GRC lightweight partition board and ceramic plate

- A plate made of ceramsite concrete, usually a non - load - bearing wallboard.

- Q:Wall material that kind of environmental protection?

- Glass fiber wall cloth, that is, wall fabric, the function is relatively strong, it is made of glass fiber, not only environmentally friendly, and fire anti-cracking moisture, scrub resistance, good care, life of more than 10 years. Whether the project or home improvement is a good choice.

- Q:Does the wall paint the shear wall need to hang the fibrous web?

- The role of fiber web: Cement concrete for the reticular fiber into the concrete, the concrete mixing process, the fiber optic cable between the horizontal connection can be the concrete's own rubbing and friction play a role in the formation of fiber monofilament or mesh structure fully open, thus To achieve a large number of polypropylene fiber monofilament to play the effect of cracking. Cement concrete special mesh fiber is extremely effective in controlling the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracks, to prevent and inhibit the formation and development of cracks. As a new concrete with anti-cracking fiber, concrete with cement concrete mesh fiber is becoming the glass fiber, steel fiber fiber concrete industry research and application of hot

- Q:What is the quality of the light barrier now?

- 1. Thermal insulation performance: insulation than the thickness of 570mm brick wall, can greatly reduce the cooling and heating and other electricity, burning costs, can be described as the best choice for energy conservation. 2. Construction speed: easy to install, more than 8 times faster than the concrete pouring method; wall panels can be sawed, can be nailed, drillable, can be arbitrarily cut, free manufacturing structure. 3. Soundproof and waterproof fire performance: sound insulation up to 45dB, the plate has a self-waterproof function, fire resistance of 2.5 hours or more. Anti-freeze-thaw cycle more than 25 times, moisture-proof performance testing projects have reached the national standard.

- Q:Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound absorption, sound insulation, insulation, ring glass board ceiling construction process

- Q:What are the lightweight wallboard materials?

- The traditional brick wall has some limitations, and now the building has begun to speak lightweight wall materials used in the external walls, the effect is good, in the partition wall material selection, lightweight partition material can And bricks to match. And the new lightweight partition material, energy saving and environmental protection, light and easy to use, according to the current development situation, the use of brick wall material is still more. This is mainly the people affected by the traditional, the use of traditional materials feel more at ease. More solid.

- Q:FRP can be used to make walls

- If the use of fiberglass do wall to see and what it is connected to the medium, or very easy to stratify, if it is in the cement surface to do the wall, I suggest you use epoxy resin, resin and sub-reinforced resin and food Grade resin, with food grade resin to do, no harm to the body, that is not food-grade, after curing the harm to the human body than other decorative materials damage small

- Q:What is GRC and can I paint it?

- GRC is also called grc components, refers to the fiberglass made of component-type material, grc shape is based on the external wall of the cad drawings to design, generally do not recommend making paint, grc's exterior decoration has its own treatment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Wall Panel with Fabric HC-387

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords