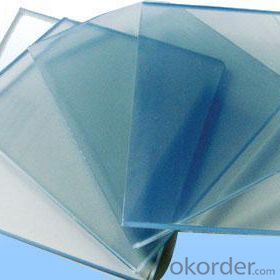

FRP Roofing Panel - Fibreglass Reinforced Polyester (FRP) Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fibreglass / Fiberglass Reinforced Plastic (FRP) or Glass Fiber Reinforced Plastic (GRP) is composed of thermosetting plastics and reinforced fiberglass, Greater than that of steel products and aluminum products in specific tenacity. Products in the ultra-low temperature or high temperature will not happen brittle fracture, deformation and to prevent heat transfer. Corrosion products in the environment anti-aging, yellowing resistance, corrosion resistance, friction resistance, easy to clean. Can be instead of aluminum, stainless steel plates, tiles and so on.

FEATURES

Corrosion resistance,last 10-15 years life span

Color stable.

Sound absorption and heat insulation.

Good water resistance.

Fireproof resistance.

Easy to install.

Good impact and low temperature resistance.

Light weight.

Stable volume.

SPECIFICATIONS

| Name: | Fibreglass Reinforced Polyester(FRP ) Sheet |

| Material: | Protective film, Unsaturated resin polyester, Fiberglass |

| Weight: | 1800g/2400g/2750g/3050g Square meter |

| Thickness: | 0.8~3.0mm |

| Length: | Customized |

| Temp: | used in -40°c to 140 °c |

| OEM: | Welcomed |

| Color: | Clear/Blue |

PICTURES

- Q: Can FRP roofing panels be installed over existing roofing materials?

- In certain cases, it is possible to install FRP (Fiberglass Reinforced Plastic) roofing panels over existing roofing materials. However, before proceeding with this installation method, several factors should be taken into consideration. Firstly, it is crucial to assess the condition of the existing roofing materials. If the previous roof is in good condition without any signs of damage or deterioration, it may be suitable for installing FRP panels on top. However, if the existing roof is severely damaged or has structural issues, it is advisable to completely remove it before installing FRP panels. Secondly, the weight-bearing capacity of the existing roof structure needs to be evaluated. Although FRP roofing panels are relatively lightweight, they still exert a certain amount of weight that must be supported by the underlying structure. It is essential to ensure that the existing structure can withstand the additional load of the FRP panels. Consulting a structural engineer or a roofing professional is recommended to assess the roof's structural integrity. Thirdly, proper preparation of the existing roof surface is vital for a successful installation. The surface should be thoroughly cleaned and free from any debris, loose materials, or contaminants. Additionally, any necessary repairs or adjustments should be made to ensure a smooth and even surface for the installation of the FRP panels. Lastly, it is crucial to follow the manufacturer's guidelines and recommendations for installing FRP roofing panels over existing materials. Each manufacturer may have specific instructions regarding the installation process, including the use of adhesives, fasteners, or sealants. In conclusion, while it is possible to install FRP roofing panels over existing roofing materials, it is important to consider the condition of the existing roof, the weight-bearing capacity of the structure, proper surface preparation, and adherence to manufacturer guidelines. Consulting a roofing professional is highly recommended to ensure a safe and proper installation.

- Q: Are FRP roofing panels suitable for recreational vehicles?

- Yes, FRP (Fiberglass Reinforced Panels) roofing panels are suitable for recreational vehicles. These panels are made from a combination of fiberglass and resin, which makes them lightweight yet durable. They are resistant to corrosion, UV rays, and extreme weather conditions, which are all important factors for RVs that are constantly exposed to the elements. FRP roofing panels also provide excellent insulation properties, helping to keep the interior of the RV cool in hot weather and warm in cold weather. This can greatly enhance the overall comfort level inside the vehicle, especially during long trips. Additionally, FRP panels are easy to install and maintain. They can be easily cut to fit the desired size and shape, allowing for customization and flexibility during the installation process. They are also resistant to mold, mildew, and rotting, ensuring a longer lifespan for the RV roof. Overall, FRP roofing panels are a great choice for recreational vehicles due to their lightweight nature, durability, weather resistance, insulation properties, and ease of installation and maintenance.

- Q: Can FRP roofing panels be used for commercial awnings?

- Commercial awnings can indeed utilize FRP roofing panels. Renowned for their durability, lightweight composition, and resistance to corrosion, FRP panels have gained popularity across a range of applications, including roofing. In the case of commercial awnings, FRP panels offer exceptional protection against various elements, such as rain, snow, and harmful UV rays. Furthermore, they come in diverse colors and designs, facilitating customization to harmonize with the visual appeal of the commercial establishment. Moreover, FRP panels boast a relatively simple installation process and require minimal maintenance, resulting in a cost-effective choice for commercial awnings.

- Q: Are FRP roofing panels suitable for industrial applications?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are indeed suitable for industrial applications. FRP roofing panels have a number of qualities that make them well-suited for industrial settings. Firstly, FRP panels are highly durable and long-lasting. They are resistant to corrosion, weathering, and UV radiation, which are all common challenges faced in industrial environments. This durability ensures that FRP panels can withstand harsh conditions and provide reliable protection for a long period of time. Furthermore, FRP roofing panels are lightweight yet strong, making them easy to handle and install. Their lightweight nature reduces the load on the structure, which can be particularly advantageous in industrial applications where large roof areas need to be covered. Additionally, their strength allows them to support heavy equipment or machinery that may be present in industrial buildings. Another important aspect is that FRP panels are non-conductive and provide excellent insulation properties. This is particularly valuable in industrial settings where electrical equipment or high temperatures may be present. FRP panels can help to regulate heat transfer and reduce energy consumption, contributing to a more energy-efficient and cost-effective operation. Moreover, FRP roofing panels are low maintenance. They are resistant to chemicals and do not require frequent painting or coating, unlike other roofing materials commonly used in industrial settings. This results in reduced maintenance costs and efforts over the lifespan of the panels. Lastly, FRP panels are available in a variety of profiles, colors, and sizes, allowing for customization to suit specific industrial requirements. This versatility ensures that FRP panels can be adapted to various industrial applications, such as warehouses, manufacturing facilities, chemical plants, and more. In conclusion, FRP roofing panels are indeed suitable for industrial applications due to their durability, lightweight yet strong nature, non-conductive insulation properties, low maintenance requirements, and versatility in terms of customization. They provide reliable protection, reduce costs, and contribute to a safer and more efficient industrial environment.

- Q: Are FRP roofing panels resistant to yellowing over time?

- Generally, FRP (Fiberglass Reinforced Plastic) roofing panels do not yellow over time. These panels are constructed with a specialized gel coating that offers protection against UV rays, which are the primary cause of yellowing and discoloration. This gel coating effectively prevents the panels from fading or yellowing due to extended exposure to sunlight. Moreover, FRP panels are designed to be robust and enduring, maintaining their original color and appearance for numerous years. However, it is essential to acknowledge that the degree of resistance to yellowing may vary depending on the quality of the FRP panels and the specific manufacturer. To ensure optimal long-term performance, it is advisable to select high-quality FRP panels from reputable suppliers.

- Q: Can FRP roofing panels be used in parking structures?

- Yes, FRP roofing panels can be used in parking structures. FRP (Fiberglass Reinforced Panels) are lightweight, durable, and have excellent resistance to corrosion, making them suitable for parking structures where exposure to weather and moisture is common. They also provide good insulation and can be easily installed, making them a cost-effective choice for parking structures.

- Q: Can FRP roofing panels be used for carports and garages?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can certainly be used for carports and garages. FRP panels are highly durable, lightweight, and resistant to various weather conditions, making them an ideal choice for such structures. They offer excellent protection against UV rays, corrosion, and impact, which are common concerns in carports and garages. Additionally, FRP panels are relatively easy to install and maintain, making them a practical and cost-effective roofing solution for these types of applications.

- Q: Can FRP roofing panels be installed on both residential and commercial gazebos?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on both residential and commercial gazebos. FRP panels are versatile and durable, making them suitable for various applications, including outdoor structures like gazebos. They provide excellent weather resistance, UV protection, and long-lasting performance, making them a popular choice for both residential and commercial settings.

- Q: Are FRP roofing panels prone to warping from heavy machinery?

- The durability and resistance to warping of FRP roofing panels are well-known. However, exposure to heavy machinery may result in warping, depending on various factors. To begin with, the resistance to warping of FRP roofing panels is greatly influenced by their thickness and quality. Thicker panels with a higher fiberglass content are less likely to warp under heavy machinery loads compared to thinner or lower-quality panels. Additionally, the type and weight of the heavy machinery can affect the probability of warping. While FRP panels can withstand normal loads like snow or wind, excessive weight from heavy machinery can surpass their load-bearing capacity and potentially cause warping. Moreover, the condition of the underlying support structure is crucial. If the structure is weak or incapable of handling the weight of heavy machinery, it can create localized pressure points on the FRP panels, increasing the risk of warping. Proper installation is also vital in preventing warping. Inadequate fastening of the panels or gaps and uneven pressure distribution during installation can contribute to warping, particularly under heavy machinery loads. To minimize the possibility of warping, it is advisable to seek guidance from a professional roofing contractor with expertise in FRP installations. They can evaluate the specific requirements of the roofing project, taking into account the type and weight of machinery involved, and recommend suitable panel thickness, quality, and installation techniques to ensure maximum durability while minimizing the risk of warping.

- Q: Are FRP roofing panels suitable for areas with heavy snowfall?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for areas with heavy snowfall. FRP roofing panels are highly durable and can withstand heavy snow loads without cracking or breaking. They have excellent structural integrity and are designed to support the weight of snow accumulation. Additionally, FRP panels have a smooth surface that allows snow to easily slide off, reducing the risk of snow buildup and potential structural damage. However, it is still important to ensure proper installation and maintenance to ensure the longevity and performance of FRP roofing panels in heavy snowfall areas.

Send your message to us

FRP Roofing Panel - Fibreglass Reinforced Polyester (FRP) Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords