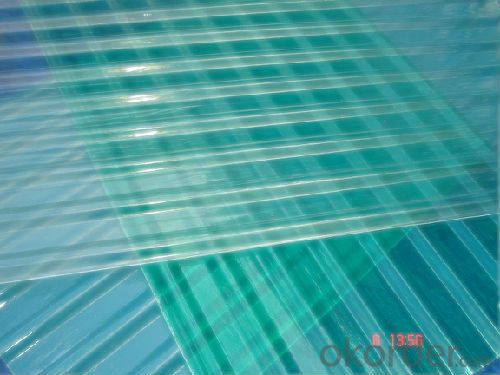

Fiber Reinforcement Plastic Flat Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Fiber Reinforcement Plastic Flat Panel

The parts made via Hand Layer-up FRP(Fiberglass Reinforced Plastic) are created by applying liquid resin and fiberglass mat along with gel-coat onto an open-faced mould. The fiberglass mat will be laid into the moulds and the resin will be brushed into the fiberglass mat carefully according to the temperature and humidity situations. The semi-product after demoulded will be trimmed according to the drawings. Then the parts will be cleaned and polished to be packed.

Hand Layer-up parts are lighter and perform better on high strength-to-weight ratios. The parts made from hand layer-up FRP are with one side smooth-the gloss can be above 80. Now these parts are widely used on boat hulls, auto parts, truck and tractor covers, chemical retainers, heavy equipment panels, even rubbish cabins etc.

Applications of Fiber Reinforcement Plastic Flat Panel

1.Company building,industry building,public building,beautify the factory premises adopting the light.

2.Decorating the inside and outside of the modern business building.

3.Sound absorbtion wall for freeway,high-speed railway and sidings.

4.Subway exits,parking lots,garage tents,Bus stations,terminals,shopping arcades,large stadium and rain tents,pagodas,hallway tents.

5.Building ceiling of greenhouse

Advantage of Fiber Reinforcement Plastic Flat Panel

1. Corrosion resistance

products are resistant to the corrosion of gas and liquid of acids, alkalis, salt, and organic solvent so that they can avoid the problem of rusting steel and rotten wood.

2. Light weight and high intensity

fiberglass products are molded through the solidification of fiberglass and resin under high temperature. Its density is only one quarter of that of steel, and two-thirds of that of aluminum. But its intensity is ten times that of PVC, exceeding the aluminum products and reaching the level of common carbon steel. Due to its light weight, the products require less base support and possess the features of easy installation and low costs.

3. Inflaming Retarding

The common oxygen index of common fiberglass products is above 32 (according to GB8924). By design, the flame spreading index of the high inflaming retarding ethylene products is below 10, which meets the requirements of engineering fire resistance for safety.

4. Collision Resistance and Fatigue Resistance

fiberglass products can resist collision and keep the original shape after repeated bending so as to be used as spring.

5. Age Resistance

The normal longevity is more than 20 years. The research result shows that the intensity will still retain more than 85% after 20 years’ exposure to the atmosphere.

6.Good appearance and Easy Maintenance

The color slurry offiberglass products is mixed with resin to make the color bright and difficult to fade. No painting is needed on the surface which is clean after washing.

Main Specification of Fiber Reinforcement Plastic Flat Panel:

Item | Parameters |

Thickness | 0.8mm~4.0mm |

Width | <2.6m |

Length | 100m/roll & Pcs of special size |

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q:Can FRP roofing panels be used in agricultural buildings?

- Agricultural buildings can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. FRP panels possess a reputation for being robust, sturdy, and capable of withstanding diverse weather conditions, which renders them suitable for agricultural settings. These panels offer exceptional protection against UV rays, corrosion, and chemicals, making them an ideal choice for agricultural buildings that frequently encounter these elements. Furthermore, FRP roofing panels are lightweight, easy to install, and necessitate minimal upkeep, making them a cost-effective option for farmers and agricultural enterprises. All in all, due to their durability, weather resistance, and low maintenance needs, FRP roofing panels can be relied upon as a dependable choice for agricultural buildings.

- Q:Do FRP roofing panels require special ventilation?

- Yes, FRP (fiberglass reinforced plastic) roofing panels do require special ventilation. Proper ventilation is important to prevent heat build-up and condensation underneath the panels. Without sufficient ventilation, the trapped heat can cause the panels to warp or deteriorate over time. Additionally, condensation can lead to moisture-related issues such as mold and mildew growth. To ensure the longevity and performance of FRP roofing panels, it is recommended to install proper ventilation systems such as ridge vents, soffit vents, or exhaust fans. These ventilation systems will allow for proper air circulation, helping to regulate temperature and reduce the risk of moisture-related problems.

- Q:Can FRP roofing panels be recycled at the end of their lifespan?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be recycled at the end of their lifespan. FRP is a composite material made up of a plastic resin reinforced with fibers, usually fiberglass. The recyclability of FRP roofing panels depends on the specific recycling facilities available in the region. The recycling process for FRP panels involves grinding them into small pieces or shredding them to separate the plastic resin from the fibers. The separated components can then be reused or repurposed for various applications. The plastic resin can be melted down and reused in the manufacturing of new plastic products, while the fibers can be used in the production of reinforcements for concrete or other composite materials. It is worth noting that not all recycling facilities are equipped to handle FRP panels due to their composite nature and the challenges associated with separating the plastic resin from the fibers. However, as the demand for sustainable practices and the recycling of composite materials increases, more specialized recycling facilities are emerging to handle FRP and other composite materials. To ensure the proper disposal and recycling of FRP roofing panels, it is recommended to contact local recycling facilities or waste management companies to inquire about their capabilities and procedures for recycling FRP. Additionally, manufacturers and suppliers of FRP roofing panels may have specific recycling programs or partnerships in place to facilitate the recycling process.

- Q:Can FRP roofing panels be used for patio covers?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for patio covers. FRP roofing panels are lightweight, durable, and resistant to various weather conditions, making them an ideal choice for patio covers. They are designed to withstand UV rays, extreme temperatures, and moisture, ensuring long-lasting performance. Additionally, FRP panels come in a variety of colors, styles, and sizes, allowing you to choose the perfect option for your patio cover. They are easy to install, low maintenance, and can provide a beautiful and functional addition to your outdoor space.

- Q:Can FRP roofing panels be used for interior applications?

- Yes, FRP roofing panels can be used for interior applications. They are versatile and can be installed in various indoor spaces such as commercial buildings, warehouses, and even residential areas. FRP panels provide excellent insulation, durability, and resistance to moisture and chemicals, making them suitable for interior environments that require these features.

- Q:Are FRP roofing panels prone to warping from nearby construction?

- FRP (Fiberglass Reinforced Plastic) roofing panels are generally known for their durability and resistance to warping. However, their susceptibility to warping can depend on various factors, including the quality of the panels and the proximity and intensity of nearby construction activities. While FRP roofing panels are designed to withstand external forces, they can be affected by excessive heat, direct sunlight, or significant vibrations caused by nearby construction. If the construction activities generate excessive heat or vibrations that directly impact the panels, there is a possibility that warping may occur. To minimize the risk of warping, it is advisable to choose high-quality FRP roofing panels that are specifically designed to withstand external forces. Additionally, considering the location and timing of nearby construction activities can also help mitigate any potential risks. It may be necessary to take precautionary measures, such as providing additional support or protection for the panels during the construction period. Overall, while FRP roofing panels are generally resistant to warping, it is essential to assess the specific circumstances of the nearby construction and take appropriate measures to ensure the longevity and stability of the panels. Consulting with a professional roofing contractor or the manufacturer of the FRP panels can provide valuable guidance in determining the best course of action in such situations.

- Q:Are FRP roofing panels suitable for military or defense applications?

- Yes, FRP (Fiber Reinforced Polymer) roofing panels can be suitable for military or defense applications. FRP panels offer numerous advantages that make them ideal for such applications. Firstly, FRP panels are incredibly strong and durable. They have a high strength-to-weight ratio, meaning they are lightweight yet possess excellent structural integrity. This makes them capable of withstanding extreme weather conditions, including heavy rain, strong winds, and even impact from projectiles or explosions. Consequently, they can provide reliable protection for military structures such as barracks, hangars, or command centers. Secondly, FRP panels are resistant to corrosion and chemicals. This is a crucial feature for military applications, as defense infrastructure is often exposed to harsh environments, including saltwater, chemicals, and pollutants. FRP panels do not rust, corrode, or degrade when exposed to these elements, ensuring their longevity and reliability. Furthermore, FRP roofing panels offer excellent thermal insulation properties. They have low thermal conductivity, meaning they can effectively regulate the internal temperature of military buildings, reducing the need for excessive heating or cooling. This energy efficiency can contribute to cost savings and enhance sustainability efforts. Additionally, FRP panels are versatile and customizable. They can be manufactured in various sizes, shapes, and colors, allowing for flexibility in design and aesthetics. This adaptability is beneficial for military applications, as it enables seamless integration with existing structures or the creation of camouflage patterns to blend in with the surroundings. Lastly, FRP roofing panels are relatively easy to install and maintain. They can be quickly and securely fixed onto the framework, reducing labor costs and time. Moreover, due to their resistance to corrosion, FRP panels require minimal maintenance and can have a significantly longer lifespan compared to traditional roofing materials. In conclusion, FRP roofing panels are indeed suitable for military or defense applications due to their strength, durability, corrosion resistance, thermal insulation properties, versatility, and ease of installation and maintenance. These features make FRP panels a reliable choice for protecting military structures and ensuring the longevity and functionality of defense infrastructure.

- Q:Are FRP roofing panels available in different thicknesses?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are available in different thicknesses. The thickness of FRP roofing panels can vary depending on the specific requirements of the project or application. Common thickness options for FRP roofing panels range from 0.8mm to 3mm, although thicker panels may also be available for specific purposes. The choice of thickness often depends on factors such as the desired level of durability, insulation properties, and load-bearing capacity required for the roofing application. It is important to consult with a professional or supplier to determine the most suitable thickness of FRP roofing panels for your specific needs.

- Q:Are FRP roofing panels resistant to water leaks?

- FRP roofing panels boast a remarkable ability to resist water leaks. Renowned for their exceptional water resistance, these panels effectively ward off any water infiltration through the roof. This is owed to the inherent characteristics of the material, which consists of a blend of fiberglass and plastic resin. The fiberglass grants the panels robustness and longevity, while the plastic resin serves as a protective barrier against water intrusion. Moreover, FRP panels are commonly installed with overlapping seams and sealed using silicone or other waterproofing substances, thereby further bolstering their resistance to water leaks. Nevertheless, it is vital to highlight the significance of proper installation and maintenance procedures in order to guarantee optimal performance and prevent any potential water leaks from occurring.

- Q:Can FRP roofing panels be cut to size on-site?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be cut to size on-site. FRP panels are relatively easy to cut using common tools such as circular saws, jigsaws, or even basic hand tools like utility knives. However, it is important to follow the manufacturer's guidelines and recommendations when cutting FRP panels to ensure a clean and accurate cut. Additionally, proper safety measures should be taken, such as wearing protective eyewear and gloves, as cutting FRP panels can generate dust and small particles. Overall, cutting FRP roofing panels on-site allows for customization and flexibility in fitting the panels to the specific dimensions of a project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Reinforcement Plastic Flat Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords