Fiber Reinforce Plastic Sheet Panel with 0.5 mm Thinkness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Reinforce Plastic Sheet Panel with 0.5 mm Thinkness

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1.light weight,high strength

2.excellent anti-corrosion performance

3.electric,heat and sound insulation

4.maintenance free

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

Good light transmittance.

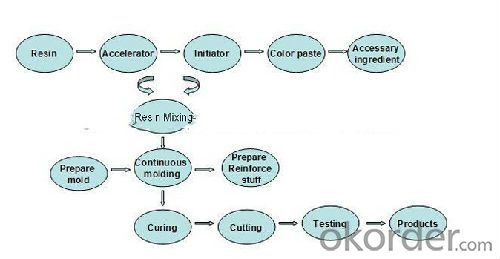

Production Process

Specification

Resin:Ortho Polyester (ORP), Iso polyester (ISO) , Vinyl ester (VE)

Size: Width Max. 3000 mm,Length customized

Thickness: 2-20mm

Surface: smooth with gel coat or not

Color: Green, yellow, grey, red, black, or any optional to you.

Chemical Resistance: VE > ISO > ORP

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q:What is the cost of FRP roofing panels compared to other roofing materials?

- The cost of FRP (Fiber Reinforced Plastic) roofing panels can vary depending on various factors such as the size of the project, the specific brand and quality of the panels, and the location. However, generally speaking, FRP roofing panels tend to be more cost-effective compared to other roofing materials. When compared to traditional roofing materials such as metal, tile, or shingles, FRP panels are often more affordable. This is primarily due to the lower cost of manufacturing FRP panels and the ease of installation, which can save on labor costs. Additionally, FRP roofing panels are lightweight, which can further reduce installation costs as they are easier and faster to install compared to heavier materials. This can also contribute to overall cost savings in terms of structural support requirements. Furthermore, FRP roofing panels are known for their durability and longevity, which can result in long-term cost savings. They are resistant to corrosion, UV radiation, and extreme weather conditions, making them a low-maintenance option that can withstand the test of time. This means that homeowners or building owners may save money on repairs or replacements in the future. It is important to note that while FRP roofing panels may offer cost advantages, it is still recommended to obtain quotes from various suppliers and consider the specific requirements of your project before making a final decision. Overall, FRP roofing panels are generally considered a cost-effective option in comparison to other roofing materials.

- Q:Can FRP roofing panels be used in mobile homes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in mobile homes. These panels are lightweight, durable, and resistant to extreme weather conditions, making them a suitable choice for mobile homes. Additionally, FRP roofing panels provide superior insulation and are easy to install, making them an efficient and cost-effective roofing option for mobile homes.

- Q:Are FRP roofing panels compatible with different types of roofing systems?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally compatible with different types of roofing systems. FRP panels are versatile and can be used with various roofing systems including flat roofs, sloped roofs, and metal roofs. They can be installed as a standalone roofing system or as an overlay on top of existing roofs. FRP panels are lightweight, durable, and resistant to corrosion, making them suitable for use in different climates and environments. They can withstand extreme weather conditions, including high winds, heavy rain, and snow. Furthermore, FRP panels can be easily integrated with other roofing materials such as asphalt shingles, metal sheets, or clay tiles. This allows for a seamless transition between different roofing materials, ensuring a watertight and aesthetically pleasing roof system. However, it is important to consult with a professional roofing contractor or manufacturer to ensure the compatibility of FRP panels with specific roofing systems. Factors such as structural support, load-bearing capacity, and installation requirements may vary depending on the type of roofing system. Consulting with experts will help ensure that the FRP panels are installed correctly and in accordance with the manufacturer's guidelines.

- Q:Can FRP roofing panels be used in zoos or animal enclosures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in zoos or animal enclosures. FRP panels are a popular choice for roofing solutions due to their durability, strength, and resistance to various environmental conditions. They are lightweight, easy to install, and have excellent weatherability, making them suitable for outdoor applications such as animal enclosures. FRP panels are also resistant to corrosion, moisture, and UV radiation, which are important factors to consider when housing animals. They provide a protective barrier against harsh weather elements, ensuring the safety and comfort of the animals. Furthermore, FRP panels can be customized to fit specific enclosure requirements, including size, shape, and color. This flexibility allows zookeepers to create enclosures that mimic the natural habitat of the animals, promoting their well-being and overall health. Additionally, FRP panels are non-toxic and easy to clean, which is crucial for maintaining hygiene in animal enclosures. They can be easily washed and disinfected, preventing the growth of bacteria and ensuring a safe environment for both the animals and the zookeepers. In conclusion, FRP roofing panels are an excellent choice for use in zoos or animal enclosures. Their durability, resistance to environmental conditions, and customizability make them suitable for creating safe and comfortable habitats for a variety of animals.

- Q:Are FRP roofing panels suitable for greenhouses?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for greenhouses. FRP panels are known for their durability, strength, and resistance to weathering, making them an excellent choice for greenhouse applications. The panels are lightweight, yet provide excellent insulation, allowing for better temperature control and energy efficiency within the greenhouse. Additionally, FRP panels are translucent, allowing natural sunlight to penetrate and distribute evenly throughout the greenhouse, promoting healthy plant growth. Furthermore, FRP panels are resistant to UV radiation, chemicals, and moisture, ensuring a longer lifespan and reduced maintenance costs. Overall, FRP roofing panels are a reliable and cost-effective choice for greenhouse construction.

- Q:Can FRP roofing panels be used for architectural applications?

- Yes, FRP roofing panels can be used for architectural applications. FRP (Fiberglass Reinforced Plastic) roofing panels provide durability, resistance to corrosion, and are lightweight, making them a suitable choice for architectural projects. They can be used in various architectural applications such as skylights, canopies, and translucent roofing systems, offering both functional and aesthetic benefits.

- Q:Are FRP roofing panels suitable for historical buildings?

- Determining the appropriateness of FRP roofing panels for historical buildings relies on a few factors. Firstly, it is crucial to take into account the specific requirements and guidelines for conserving historical structures in the given area. Some preservation societies or organizations may have stringent regulations regarding the utilization of certain materials, including roofing materials. Thus, consulting with local authorities or historical preservation experts is necessary to ensure compliance with any restrictions. Secondly, the evaluation of the historical building's condition and its roofing system is essential. If the existing roof is significantly damaged or deteriorated, replacing it with FRP roofing panels could be a viable choice. The lightweight nature of FRP panels can reduce the burden on the structure, potentially minimizing the need for additional structural reinforcements. Moreover, FRP roofing panels offer several advantages that can benefit historical buildings. They possess a high resistance to corrosion, UV rays, and chemicals, ensuring durability and longevity. This is particularly advantageous for historical buildings exposed to harsh weather conditions or situated near industrial areas. Furthermore, FRP panels can be designed to imitate traditional roofing materials, such as clay tiles or slate, thus preserving the aesthetic allure of the historical building. They are available in various colors, textures, and profiles, allowing for customization to suit the architectural style of the structure. Nevertheless, it is essential to consider the potential impact of utilizing FRP panels on the overall visual appearance and authenticity of the historical building. Some preservationists argue that using modern materials like FRP may compromise the historical integrity and character of the structure. In such cases, alternative roofing materials that closely resemble the original ones may be preferred. In conclusion, the suitability of FRP roofing panels for historical buildings relies on various factors, including local regulations, the building's condition, and preservation objectives. Consulting with historical preservation experts and considering the building's specific needs can help determine if FRP panels are a suitable option.

- Q:Can FRP roofing panels be used for carports or garages?

- Yes, FRP roofing panels can be used for carports or garages. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and weather-resistant, making them suitable for use in outdoor structures like carports and garages. They provide excellent protection against UV rays, rain, and other environmental factors, ensuring the safety and longevity of the carport or garage.

- Q:What are the advantages of using FRP roofing panel?

- The advantages of using FRP roofing panels include their lightweight nature, durability, and resistance to corrosion, chemicals, and UV rays. They also offer excellent insulation properties, easy installation, and low maintenance requirements. Additionally, FRP roofing panels are cost-effective and have a long lifespan, making them an ideal choice for various applications.

- Q:Do FRP roofing panels require any special certifications or approvals?

- Yes, FRP roofing panels typically require special certifications or approvals depending on the specific building codes and regulations in each region. These certifications ensure that the panels meet certain safety standards and performance criteria, providing assurance to customers and authorities that they can be used in construction projects. It is advisable to consult local authorities or building professionals to determine the specific certifications and approvals required for FRP roofing panels in a particular area.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Reinforce Plastic Sheet Panel with 0.5 mm Thinkness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords