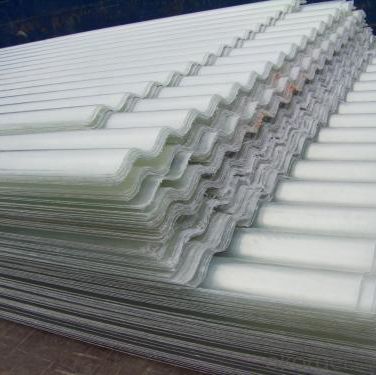

Insulated FRP Laminated Roof Panels - FRP GRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

>> Weatherability: In the temperature range of -40 ℃ - 120 ℃ to maintain stable performance, no high-temperature softening, cold brittle phenomenon;

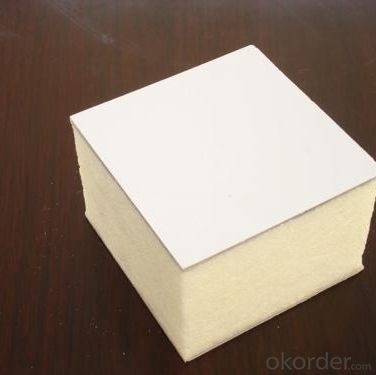

>> Low thermal conductivity & good insulation performance;

>> Non-toxic, non-asbestos, etc., in line with world health standards;

>> No moss & prevent microbial growth;

>> High impact and resistant to strong wind;

>> Safe and reliable, Not combustion-supporting in open fire;

>> Corrosion resistance, suitable for chemical workshop roof, such as fertilizer plants, electroplating factory

SPECIFICATIONS

Item | Description | ||

| Material | FRP, ASA, PVC | ||

| Thickness | 1.0mm - 3.0mm | ||

| Color | Clear, milk white, blue, green, red | ||

| Type | 475, 666, 760, 820, 840, 860, 900, 950, 980, 1050, can be customized | ||

| Shelf life | 15 years | ||

PICTURES

- Q: Are FRP roofing panels suitable for office buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for office buildings. FRP panels have several qualities that make them a popular choice for commercial structures. Firstly, FRP panels are lightweight yet durable, making them easy to install and maintain. This is advantageous for office buildings, as it reduces the need for extensive structural modifications and allows for faster construction or renovation processes. Secondly, FRP panels offer excellent resistance to harsh weather conditions, including UV rays, extreme temperatures, and high winds. This is crucial for office buildings, as they are often exposed to the elements and need a roofing material that can withstand long-term exposure without deteriorating or requiring frequent repairs. Additionally, FRP roofing panels are available in various colors, finishes, and designs, allowing for aesthetic customization to suit the architectural style and branding of the office building. This versatility makes FRP panels an attractive option for businesses looking to enhance the visual appeal of their office space. Furthermore, FRP panels are known for their energy efficiency. They have excellent insulation properties, which help regulate the temperature inside the office building, reducing the reliance on heating and cooling systems and ultimately lowering energy costs. Lastly, FRP roofing panels are cost-effective compared to other roofing materials. They have a long lifespan and require minimal maintenance, resulting in reduced long-term expenses for the office building owner. In conclusion, FRP roofing panels are a suitable choice for office buildings due to their lightweight yet durable nature, resistance to harsh weather conditions, aesthetic versatility, energy efficiency, and cost-effectiveness.

- Q: Are FRP roofing panels suitable for recreational vehicles?

- Yes, FRP roofing panels are suitable for recreational vehicles. FRP (Fiberglass Reinforced Plastic) offers several advantages such as durability, lightweight construction, resistance to corrosion, and excellent insulation properties. These qualities make FRP roofing panels a suitable choice for recreational vehicles, as they can withstand various weather conditions and provide thermal comfort for the occupants. Additionally, FRP panels are easy to maintain and can be customized to fit the specific requirements of a recreational vehicle.

- Q: What is the installation process for FRP roofing panels?

- Typically, the installation process for FRP (Fiberglass Reinforced Plastic) roofing panels involves the following steps: To begin, the roof surface must be thoroughly cleaned and prepared for installation. This may include the removal of existing roofing materials, cleaning the surface, and ensuring it is smooth and clear of any debris or protrusions. Accurate measurements of the roof are then taken to determine the required size and number of FRP panels. These panels are subsequently cut to the appropriate dimensions using a saw or similar cutting tool. It is important to wear safety glasses and gloves when cutting FRP panels for protection. Next, the first panel is positioned at the edge of the roof and securely fastened using suitable fasteners such as screws or nails. The subsequent panels are then overlapped with the previous one and also fastened down in a similar manner. This overlapping technique ensures a watertight seal and prevents any water infiltration. Once all the panels are successfully installed, any gaps or joints between them are sealed using a suitable sealant. This further enhances the waterproofing properties of the roof. Additionally, trim pieces may be used to cover exposed edges or corners, providing a more polished appearance. To ensure a proper and durable installation, it is crucial to carefully follow the manufacturer's instructions and guidelines. If you are unfamiliar with the installation process or have any doubts, it is recommended to consult with a professional or experienced contractor.

- Q: Are FRP roofing panels translucent or opaque?

- FRP roofing panels can be both translucent and opaque, depending on the specific type and design of the panel.

- Q: Do FRP roofing panels require a specific type of flashing?

- Yes, FRP roofing panels typically require a specific type of flashing that is compatible with the material and installation methods used for FRP roofing panels. The flashing used should be designed to provide proper waterproofing and protect against potential leaks or water damage.

- Q: Can FRP roofing panels be used for restaurants?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for restaurants. FRP panels are highly durable, weather-resistant, and provide excellent insulation, making them suitable for use in restaurant buildings. Additionally, FRP panels are lightweight and easy to install, which makes them a practical choice for roofing solutions in the restaurant industry.

- Q: Can FRP roofing panels be used for both sloped and flat roofs?

- Yes, FRP roofing panels can be used for both sloped and flat roofs. These panels are versatile and can be installed on various roof types, including sloped and flat surfaces, providing durability and protection against weather elements.

- Q: Can FRP roofing panels be used for pergolas?

- Certainly! Pergolas can indeed incorporate FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess remarkable qualities such as durability, lightness, and corrosion resistance, rendering them an exceptional option for outdoor structures like pergolas. By shielding against the elements, they enable the pleasant passage of natural light, thereby establishing an inviting and cozy open-air atmosphere. Furthermore, the simplicity of installation and maintenance associated with FRP panels makes them a highly pragmatic selection for pergolas.

- Q: Do FRP roofing panels require special cleaning or maintenance products?

- FRP roofing panels do not typically necessitate the use of specialized cleaning or maintenance products. These panels are renowned for their durability and ability to withstand damage from weather elements, making them comparably low-maintenance when compared to other roofing materials. To effectively clean FRP roofing panels, a mixture of mild detergent and water can be utilized alongside a soft-bristle brush or sponge to gently eliminate any dirt or stains. It is important to avoid abrasive materials or harsh chemicals, as they have the potential to harm the panel's surface. Routine maintenance for FRP roofing panels involves inspecting them for any indications of damage, such as cracks or leaks, and taking immediate action. Additionally, it is advisable to clear any debris, leaves, or branches that may accumulate on the roof in order to prevent potential obstructions or harm. In summary, FRP roofing panels are designed to be easily cleaned and maintained, requiring minimal specialized products or treatments. However, it is always recommended to consult the specific manufacturer's instructions for cleaning and maintenance guidelines to ensure the longevity and performance of your FRP roofing panels.

- Q: Are FRP roofing panels resistant to warping?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to warping. The unique combination of materials, including glass fibers, provides excellent strength and stability, preventing any significant warping even under extreme weather conditions.

Send your message to us

Insulated FRP Laminated Roof Panels - FRP GRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords