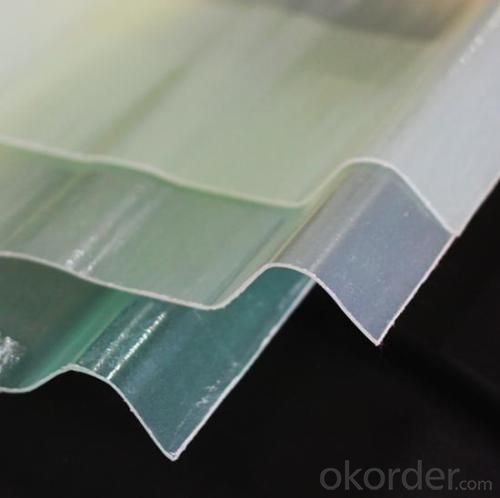

FRP Roofing Panel - Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

The FRP roof tile using in factories, warehouses, car parks, agricultural, freezer, food processing plants, restaurants, laboratory, heat-insulation sheds, weather corridors, lighting sheds, sun sheds, greenhouses, etc.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Can FRP roofing panels be curved or molded?

- FRP roofing panels possess the capability to be shaped and contoured to meet distinct shapes and designs. Their flexibility enables effortless formation to achieve the desired curvature or contour. Consequently, they are highly suitable for applications where a curved or molded roof design is sought after, such as in architectural ventures or specialized roofing installations. Furthermore, the lightweight composition of FRP panels simplifies their manipulation and shaping to conform to the desired form. Nevertheless, it is crucial to acknowledge that the degree to which FRP panels can be curved or molded may rely on the specific thickness and flexibility of the panel. To ensure proper installation and compatibility with the desired design prerequisites, it is advisable to consult the manufacturer or engage a roofing professional.

- Q: Can FRP roofing panels be recycled?

- Yes, FRP roofing panels can be recycled. FRP stands for Fiberglass Reinforced Plastic, which is a composite material made of glass fibers and resin. It is commonly used in roofing due to its durability and resistance to various weather conditions. When these panels reach the end of their life cycle, they can be recycled by removing the fiberglass fibers from the resin matrix. The fibers can then be reused in various applications, while the resin can be processed and used as a fuel source or for other purposes. Recycling FRP roofing panels helps reduce waste and supports sustainable practices in construction.

- Q: What are the advantages of using FRP roofing panels?

- There are several advantages to using FRP (Fiberglass Reinforced Plastic) roofing panels. Firstly, FRP roofing panels are extremely durable and long-lasting. They are resistant to corrosion, UV rays, and extreme weather conditions such as hail, snow, and heavy rain. This makes them ideal for use in areas prone to harsh weather or high humidity. Secondly, FRP roofing panels are lightweight yet strong. This makes them easier to handle and install compared to other roofing materials. Additionally, their strength ensures that they can withstand heavy loads without cracking or breaking, making them suitable for both residential and commercial applications. Another advantage of FRP roofing panels is their versatility. They come in a wide range of colors, textures, and profiles, allowing for various design options. They can be manufactured to mimic the appearance of other roofing materials such as shingles or tiles, providing a more aesthetically pleasing look while retaining the benefits of FRP. Additionally, FRP roofing panels offer excellent insulation properties. They can help regulate temperature and reduce energy consumption by keeping the interior of a building cooler in hot climates and warmer in cold climates. This can lead to significant cost savings on heating and cooling bills. Furthermore, FRP roofing panels are low maintenance. They are easy to clean and require minimal upkeep over their lifespan. This saves both time and money compared to traditional roofing materials that may require regular repairs or replacements. Lastly, FRP roofing panels are environmentally friendly. They are made from recycled materials and are themselves recyclable at the end of their lifespan. They also have a long lifespan, reducing the need for frequent replacements and minimizing waste. Overall, the advantages of using FRP roofing panels include durability, strength, versatility, insulation properties, low maintenance, and environmental friendliness. These make them a practical and cost-effective choice for various roofing applications.

- Q: Can FRP roofing panels be used for covered walkways in universities or college campuses?

- Covered walkways in universities or college campuses can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. The popularity of FRP panels for such purposes stems from their durability, versatility, and cost-effectiveness. These panels possess a lightweight yet sturdy nature, enabling the creation of long-span structures like covered walkways. Moreover, FRP panels demonstrate excellent resistance to harsh weather conditions, safeguarding against rain, snow, and UV radiation, all of which are particularly crucial for outdoor structures. Furthermore, universities and college campuses can personalize the walkways by selecting from a wide range of colors and designs available for FRP panels. In summary, when it comes to constructing covered walkways in educational institutions, FRP roofing panels serve as a dependable and pragmatic choice.

- Q: Are FRP roofing panels suitable for green building projects?

- FRP roofing panels are a fitting choice for green building projects as they offer numerous advantages. FRP, short for Fiber Reinforced Polymer, is a lightweight and durable material crafted from a blend of fiberglass and resin. To begin with, FRP panels boast energy efficiency. Their exceptional insulation properties aid in reducing heating and cooling expenses, thus contributing to the overall energy efficiency of the building. This fosters sustainability and environmental friendliness. Moreover, FRP panels exhibit remarkable durability and longevity. They withstand corrosion, UV radiation, and other weather elements, resulting in minimal maintenance requirements and an extended lifespan when compared to traditional roofing materials. By utilizing FRP panels, the need for frequent repairs or replacements is curtailed, thereby minimizing waste and prolonging the building's life. Additionally, FRP roofing panels are lightweight, simplifying installation and transportation processes. This diminishes the carbon footprint associated with these activities and allows for a more efficient utilization of resources during construction. Furthermore, FRP panels are recyclable. At the end of their life cycle, they can be recycled and repurposed, promoting a circular economy and reducing waste. This aligns with the principles of green building, which prioritize the adoption of sustainable and recyclable materials. In conclusion, FRP roofing panels are well-suited for green building projects due to their energy efficiency, durability, lightweight nature, and recyclability. By incorporating FRP panels into green building designs, it becomes possible to enhance the sustainability and environmental performance of the project.

- Q: Are FRP roofing panels resistant to bird damage?

- FRP roofing panels, also called fiberglass reinforced plastic roofing panels, generally have resistance against bird damage. Compared to other roofing materials like shingles or metal, FRP's durability makes it less prone to scratches, pecks, or punctures caused by birds. However, it is important to understand that no material is completely immune to bird damage. In uncommon instances, aggressive bird behavior or large birds with strong beaks might still manage to cause some harm to FRP roofing panels. To minimize the risk of bird damage, it is recommended to ensure proper installation of the panels, conduct regular inspections, and seal off any potential bird entry points. Moreover, taking preventive measures such as using bird deterrent devices or netting can further discourage birds from perching or nesting on the roof, thereby decreasing the likelihood of damage.

- Q: Are FRP roofing panels suitable for barns or agricultural buildings?

- FRP roofing panels are indeed a suitable option for barns or agricultural buildings. These panels are renowned for their durability, strength, and ability to withstand different weather conditions, making them an ideal choice for structures that require reliable protection against the elements. Moreover, FRP panels are lightweight and easy to install, making them a practical option for agricultural buildings. They also possess exceptional UV resistance, effectively preventing any damage caused by prolonged exposure to sunlight. Additionally, FRP panels exhibit high resistance to chemicals, enabling them to withstand corrosive substances commonly found in barns, such as fertilizers or animal waste. In conclusion, FRP roofing panels offer a cost-effective and long-lasting solution for barns and agricultural buildings.

- Q: Can FRP roofing panels be installed on steep-sloped roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on steep-sloped roofs. FRP panels are versatile and can be used in a variety of roofing applications, including steep-sloped roofs. However, it is important to ensure that the proper installation techniques and safety precautions are followed. Steep-sloped roofs present additional challenges due to the increased risk of falls and the need for specialized equipment. It is recommended to consult with a professional roofing contractor who is experienced in installing FRP panels on steep-sloped roofs to ensure a safe and successful installation.

- Q: Can FRP roofing panels be used for pergolas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for pergolas. FRP panels are durable, lightweight, and resistant to corrosion, making them an excellent choice for outdoor structures like pergolas. They provide protection from the elements while allowing natural light to filter through, creating a comfortable and inviting outdoor space. Additionally, FRP panels are easy to install and maintain, making them a practical choice for pergolas.

- Q: Can FRP roofing panels be used for walk-in coolers or freezers?

- Indeed, walk-in coolers or freezers can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. Renowned for their durability, strength, and ability to withstand moisture and temperature fluctuations, FRP panels prove to be an excellent choice for such purposes. Their design ensures that they remain intact even in the face of freezing temperatures, avoiding any cracking or warping that could compromise the walk-in cooler or freezer's integrity. Moreover, FRP panels possess exceptional insulation properties, effectively maintaining the desired temperature inside while minimizing energy loss. All in all, FRP roofing panels present themselves as a dependable and pragmatic option for walk-in coolers or freezers.

Send your message to us

FRP Roofing Panel - Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords