FRP Roofing Panel - Colorful Roofing Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATIONS

| Items | Date |

| Tensile Strength | 122.8Mpa |

| Tensile Modulus | 8610Mpa |

| Flexural Strength | 219.9mPA |

| Flexural Modulus | 8210Mpa |

| Barcol Hardness | 47 |

| Izod Impact | 80.4kj/m2 |

| Thermal Expansivity | 2.4X10-5 °C-1 |

| Distortion Termperature | >230°C |

| Water Absorption | 0.16%/24hrs@25°C |

| Gravity | 1.5g/cm3-1.9g/cm3 |

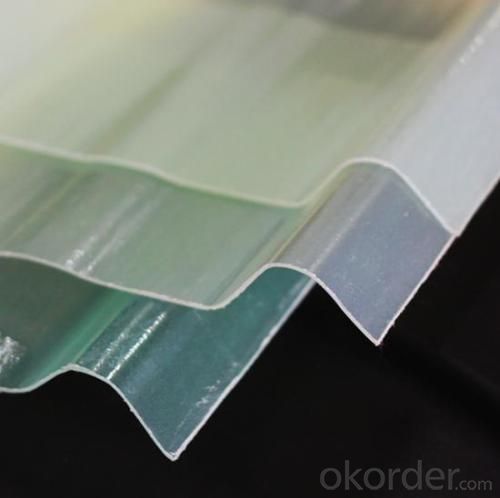

PICTURES

- Q: Can FRP roofing panels be used for covered walkways in schools or educational institutions?

- Yes, FRP roofing panels can be used for covered walkways in schools or educational institutions. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and resistant to weathering, making them an ideal choice for covered walkways. They provide protection from rain, sun, and other elements, ensuring a safe and comfortable passage for students and staff. Additionally, FRP panels are low maintenance and offer a wide range of design options, allowing for customization to match the aesthetic of the educational institution.

- Q: Can FRP roofing panels be used for covered walkways or bike shelters?

- Yes, FRP roofing panels can be used for covered walkways or bike shelters. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability, strength, and resistance to corrosion, making them a suitable choice for such structures. They provide excellent protection against weather elements, including rain, snow, and UV rays, ensuring the safety and comfort of pedestrians or cyclists underneath. Additionally, FRP roofing panels are lightweight and easy to install, making them a cost-effective solution for covered walkways or bike shelters. They also offer flexibility in design options, allowing for customization to meet specific project requirements. Therefore, FRP roofing panels are a reliable choice for creating covered walkways or bike shelters.

- Q: Can FRP roofing panels be used for awnings or canopies?

- Yes, FRP roofing panels can be used for awnings or canopies. FRP (Fiberglass Reinforced Plastic) is a durable and lightweight material that is commonly used for roofing applications. Its strength and weather resistance make it suitable for creating awnings or canopies to provide shade and protect against the elements.

- Q: Are FRP roofing panels noise resistant?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are noise resistant. The material used in these panels is designed to absorb and dampen sound waves, reducing the amount of noise that enters a building. This is particularly advantageous in areas with high levels of noise pollution, such as near airports or busy highways. Additionally, the installation of insulation materials between the panels and the building structure further enhances the noise reduction capabilities of FRP roofing panels. Overall, FRP roofing panels provide an effective solution for reducing exterior noise and creating a quieter and more comfortable indoor environment.

- Q: Do FRP roofing panels require specific safety precautions during installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require specific safety precautions during installation. Firstly, it is important to ensure that all necessary safety equipment is provided and used by the installers. This includes items such as safety harnesses, hard hats, gloves, goggles, and non-slip footwear. These safety measures are crucial to protect installers from potential falls, head injuries, hand injuries, and eye injuries. Secondly, it is important to follow proper handling and lifting techniques when working with FRP roofing panels. These panels can be heavy and awkward to maneuver, so it is important to have enough manpower and use appropriate lifting techniques to prevent strains and other lifting-related injuries. Furthermore, it is important to be cautious of the potential for electrical hazards during installation. FRP roofing panels are often installed on structures that may have electrical wiring or equipment nearby. Installers should be trained to identify and avoid electrical hazards, and it may be necessary to shut off power to certain areas during installation to minimize the risk of electric shock. Lastly, it is crucial to follow the manufacturer's guidelines and instructions for installation. FRP roofing panels may have specific requirements for installation, such as recommended temperatures, adhesives, or fasteners. By following these guidelines, installers can ensure that the panels are properly installed and minimize the risk of accidents or structural failures. In conclusion, FRP roofing panels do require specific safety precautions during installation. By providing and using the necessary safety equipment, following proper handling and lifting techniques, being cautious of electrical hazards, and following manufacturer's guidelines, installers can ensure a safe and successful installation process.

- Q: Are FRP roofing panels resistant to lightning strikes?

- FRP roofing panels, also known as fiberglass reinforced plastic panels, are not inherently resistant to lightning strikes. However, they are considered to be safer compared to other roofing materials such as metal or asphalt. The reason for this is that FRP roofing panels are non-conductive, meaning they do not conduct electricity. As a result, if lightning were to strike a structure with FRP roofing panels, the panels themselves would not attract or conduct the electrical charge of the lightning bolt. However, it is important to note that lightning can still pose a risk to any structure, regardless of the roofing material. Lightning seeks the path of least resistance to the ground, and it can travel through any conductive material, such as metal pipes or wiring, that may be present in the building. To mitigate the risk of lightning strikes, it is advisable to install a lightning protection system. This system typically includes lightning rods or air terminals installed on the highest points of the structure, as well as conductive cables that run down the building and into the ground. These components help to safely direct the electrical charge of a lightning strike away from the structure and into the ground. In summary, while FRP roofing panels are not resistant to lightning strikes, they are considered safer than some other roofing materials due to their non-conductive nature. However, it is essential to implement proper lightning protection measures to ensure the safety of any structure, regardless of the roofing material used.

- Q: Do FRP roofing panels have a smooth or textured surface?

- FRP roofing panels typically have a smooth surface.

- Q: Are FRP roofing panels suitable for government buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for government buildings. FRP panels offer a range of benefits that make them an excellent choice for government buildings. Firstly, FRP panels are highly durable and resistant to weathering, UV rays, and corrosion, ensuring a long lifespan and minimal maintenance requirements. This is particularly important for government buildings that need to withstand harsh environmental conditions over an extended period. Additionally, FRP roofing panels are lightweight, making them easy to install and reducing the load on the building's structure. This can be advantageous for government buildings with specific load-bearing requirements or older structures that may not be able to support heavier roofing materials. Another advantage of FRP roofing panels is their versatility in design and aesthetics. They are available in a variety of colors, textures, and profiles, allowing government buildings to maintain their architectural style while achieving a modern and aesthetically pleasing appearance. Furthermore, FRP panels offer excellent thermal insulation properties, helping to regulate the temperature inside the building and reduce energy consumption. This can contribute to cost savings in the long run, making FRP panels an environmentally friendly and economically viable choice for government buildings. In conclusion, FRP roofing panels are suitable for government buildings due to their durability, lightweight nature, design versatility, and thermal insulation properties. These panels can provide long-lasting protection, enhance the architectural appeal, and contribute to energy efficiency, making them an excellent choice for government buildings.

- Q: Are FRP roofing panels suitable for theme park structures?

- Yes, FRP (fiberglass reinforced polymer) roofing panels are indeed suitable for theme park structures. FRP roofing panels offer several advantages that make them an excellent choice for such applications. Firstly, FRP panels are lightweight yet incredibly strong, making them ideal for large-scale structures like roller coasters, amphitheaters, or pavilions in theme parks. Their strength-to-weight ratio allows for ease of installation and reduces the load on the supporting structure. Additionally, FRP panels are highly durable and resistant to corrosion, UV radiation, and extreme weather conditions. This makes them well-suited for theme park structures, which often require materials that can withstand constant exposure to the elements and heavy foot traffic. The UV resistance of FRP panels prevents color fading or degradation, ensuring that the theme park structures maintain their visual appeal over time. Furthermore, FRP panels offer design flexibility and can be manufactured in various colors, shapes, and sizes. This allows theme park designers to create unique and visually appealing structures that align with the park's theme or aesthetic. The lightweight nature of FRP also facilitates intricate designs that are not possible with heavier materials. Another noteworthy advantage of FRP panels is their excellent thermal insulation properties. This means that structures covered with FRP roofing panels can maintain a more comfortable temperature, reducing the need for excessive air conditioning or heating in theme park buildings. The energy efficiency provided by FRP panels can contribute to cost savings for the theme park operator. In conclusion, FRP roofing panels are indeed suitable for theme park structures. Their lightweight yet strong construction, durability, resistance to corrosion and UV radiation, design flexibility, and thermal insulation properties make them an ideal choice for creating visually appealing, long-lasting, and energy-efficient structures in theme parks.

- Q: Can FRP roofing panels be installed with insulation for improved energy efficiency?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed with insulation to improve energy efficiency. Insulation helps to regulate temperature, reduce heat transfer, and minimize energy loss, resulting in lower heating and cooling costs. When installed properly, insulation can significantly enhance the energy efficiency of FRP roofing panels.

Send your message to us

FRP Roofing Panel - Colorful Roofing Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords