High Quality FRP Roofing Panel - Fire Resistance FRP Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATION

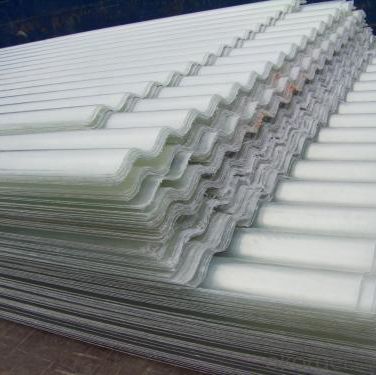

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Are FRP roofing panels resistant to fading or discoloration?

- Yes, FRP roofing panels are generally resistant to fading or discoloration due to their durable construction and protective coatings.

- Q: Do FRP roofing panels have any specific building code approvals?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do have specific building code approvals. The specific building code approvals may vary depending on the region or country, as each jurisdiction may have its own set of regulations and standards. However, in general, FRP roofing panels need to meet certain criteria to receive building code approvals. The building code approvals for FRP roofing panels typically include factors such as fire resistance, wind uplift resistance, impact resistance, and structural stability. These approvals ensure that the panels can withstand various environmental conditions and contribute to the overall safety and stability of the building. To obtain building code approvals, manufacturers of FRP roofing panels must comply with the relevant building codes and standards set forth by local regulatory bodies. This often involves rigorous testing and certification processes conducted by independent testing laboratories. These tests evaluate the panels' performance in different scenarios, such as fire exposure, wind pressure, and impact resistance. It is important for builders and contractors to verify the specific building code approvals of FRP roofing panels before using them in construction projects. This can be done by checking the product documentation provided by the manufacturer, which should clearly state the approvals and certifications obtained. By ensuring that FRP roofing panels have specific building code approvals, construction professionals can be confident that the panels meet the necessary safety and performance requirements for their intended use. This helps to maintain compliance with local building codes and regulations and promotes the overall quality and longevity of the roofing system.

- Q: Are FRP roofing panels resistant to insect infestation?

- FRP roofing panels, known as Fiberglass Reinforced Plastic, generally possess resistance against insect infestation. The material employed in FRP panels lacks appeal to insects, and their sleek surface hinders insects from locating any crevices or openings to infiltrate and infest the panels. Furthermore, FRP panels commonly receive treatment with a protective coating that augments their insect resistance. Nevertheless, it is crucial to acknowledge that while FRP panels themselves repel insects, surrounding regions such as roof edges, eaves, and vents may remain susceptible to insect infiltration. Consequently, it is advisable to adequately seal and maintain these areas to preempt any potential infestation.

- Q: Are FRP roofing panels prone to scratches?

- FRP roofing panels are generally resistant to scratches, thanks to their strong and durable composition. However, like any other surface, they can still get scratched under extreme circumstances or due to improper handling. Overall, with proper care and maintenance, FRP roofing panels should remain largely scratch-free.

- Q: Can FRP roofing panels be installed in curved structures?

- Curved structures can indeed accommodate FRP roofing panels. The flexibility and adaptability of FRP (Fiberglass Reinforced Plastic) roofing panels make them a perfect fit for installation on curved surfaces. These panels can effortlessly be molded and contoured to match the structure's curvature, ensuring a flawless and secure installation. Furthermore, FRP roofing panels are lightweight but exceptionally durable, making them a superior choice for curved structures where traditional roofing materials may not be suitable or as effective. In conclusion, FRP roofing panels offer both aesthetic allure and dependable performance, making them an excellent option for curved structures.

- Q: Can FRP roofing panels be used for theaters?

- The use of FRP roofing panels in theaters is indeed possible. These panels, made from Fiberglass Reinforced Plastic, are a versatile roofing material that offers numerous advantages for theater applications. To begin with, FRP panels are lightweight, making them easy to handle and install. This is particularly advantageous in theaters where heavy machinery or equipment may be difficult to access. Additionally, their lightweight nature reduces the strain on the theater structure, making them suitable for both new construction and retrofit projects. Furthermore, FRP panels are highly durable and resistant to various environmental factors. They can withstand extreme temperatures, UV radiation, moisture, and chemicals. This durability ensures that the roofing system remains intact and functional for an extended period, reducing the need for frequent repairs or replacements. Moreover, FRP panels have excellent light transmission properties. This allows natural daylight to enter the theater space, creating a visually appealing environment and potentially reducing the need for artificial lighting during the day. Furthermore, the light transmission properties of FRP panels can be advantageous for theater performances that require specific lighting effects or color schemes. Additionally, FRP panels come in a variety of colors, finishes, and profiles, allowing for customization to meet the aesthetic requirements of the theater. They can be manufactured to resemble traditional roofing materials, such as tiles or shingles, while still retaining the benefits of FRP. In conclusion, FRP roofing panels offer a viable solution for theaters due to their lightweight nature, durability, light transmission properties, and customization options. They provide a reliable and visually appealing roofing solution that enhances the overall theater experience.

- Q: Can FRP roofing panels be used for garages?

- Indeed, garages can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. Due to their lightweight nature, durability, and resistance to corrosion, FRP panels prove to be suitable for a range of purposes, garages included. These panels find widespread usage in residential and commercial garage settings due to their capacity to endure severe weather and offer superb insulation. Moreover, the installation process for FRP panels is effortless, and they necessitate minimal upkeep, rendering them an economical option for garage roofs.

- Q: Are FRP roofing panels resistant to discoloration?

- Yes, FRP roofing panels are generally resistant to discoloration due to their durable and UV-resistant properties.

- Q: Do FRP roofing panels require a specific type of flashing?

- Yes, FRP roofing panels typically require a specific type of flashing that is compatible with the material and installation methods used for FRP roofing panels. The flashing used should be designed to provide proper waterproofing and protect against potential leaks or water damage.

- Q: Can FRP roofing panels be used for balcony coverings?

- Balcony coverings can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. Renowned for their durability, resistance to weather, and lightweight nature, FRP panels are highly suitable for a range of applications, including balcony coverings. These panels have been specifically engineered to withstand severe environmental conditions, such as UV radiation, extreme temperatures, and moisture, rendering them an optimal choice for outdoor areas like balconies. Additionally, FRP panels are offered in various colors, finishes, and designs, allowing for customization to meet the aesthetic demands of the balcony. Furthermore, they are relatively simple to install and maintain, adding to their practicality as an option for balcony coverings. By providing protection and enhancing the overall appearance of the space, FRP panels prove to be an excellent choice for balconies.

Send your message to us

High Quality FRP Roofing Panel - Fire Resistance FRP Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords