FRP Roofing Panel - High Quality Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

The FRP roof tile using in factories, warehouses, car parks, agricultural, freezer, food processing plants, restaurants, laboratory, heat-insulation sheds, weather corridors, lighting sheds, sun sheds, greenhouses, etc.

FEATURES

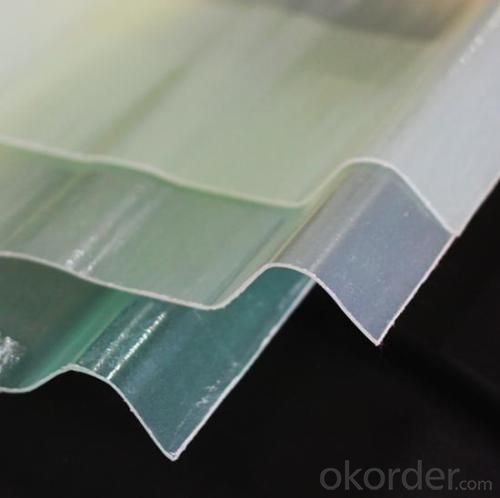

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

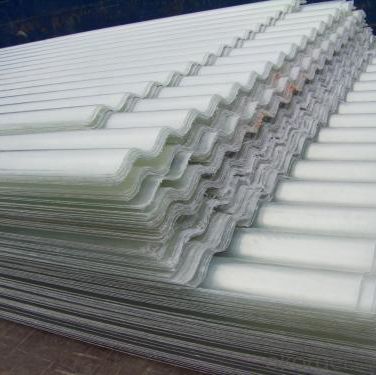

PICTURES

- Q: Do FRP roofing panels require any special cleaning or maintenance products?

- FRP roofing panels do not typically require any special cleaning or maintenance products. They are designed to be low maintenance and durable, making them resistant to mold, mildew, and staining. Regular cleaning with water and mild soap is usually sufficient to keep them looking clean and new. However, it is important to avoid using abrasive cleaners, strong chemicals, or high-pressure washing as these may damage the surface of the panels. Additionally, it is recommended to inspect the panels regularly for any signs of damage or wear and to address any issues promptly to ensure the longevity of the roofing system.

- Q: Are FRP roofing panels suitable for DIY installation?

- Yes, FRP roofing panels are suitable for DIY installation. They are lightweight, easy to handle, and can be installed using basic tools. However, it is important to have some knowledge and experience in roofing installations to ensure proper installation and avoid any potential issues. It is recommended to follow the manufacturer's guidelines and instructions for a successful DIY installation.

- Q: Can FRP roofing panels be used in areas with high levels of industrial emissions?

- FRP roofing panels are generally suitable for use in areas with high levels of industrial emissions. These panels are renowned for their durability and resistance to various chemicals, making them well-suited for harsh environments, including those with industrial emissions. However, it is crucial to take into account the specific type and concentration of industrial emissions in the area. Certain emissions, such as acidic gases or corrosive particles, may necessitate additional protective coatings or special formulations of FRP to ensure long-lasting performance. Consulting with FRP manufacturers or technical experts is also advisable. They can provide tailored guidance based on the nature of the industrial emissions and the intended use of the FRP roofing panels. Furthermore, regular maintenance and inspections should be carried out to evaluate any potential degradation or damage caused by the industrial emissions, ensuring the continuous effectiveness of the FRP roofing system.

- Q: Are FRP roofing panels suitable for residential balconies or terraces?

- FRP roofing panels are indeed a suitable option for residential balconies or terraces. These panels possess remarkable durability and weather resistance, making them an ideal choice for outdoor use. Their lightweight yet strong nature not only facilitates installation but also minimizes strain on the structure. Furthermore, FRP panels exhibit resistance against UV rays, chemicals, and corrosion, guaranteeing long-lasting performance and minimal maintenance. Additionally, they offer exceptional insulation, effectively regulating the temperature on balconies or terraces. In conclusion, FRP roofing panels represent a dependable and economical alternative for residential balconies or terraces.

- Q: What is the cost of FRP roofing panels?

- The cost of FRP (Fiberglass Reinforced Plastic) roofing panels can vary depending on various factors such as the size of the panels, thickness, quality, and brand. On average, the cost per square foot of FRP roofing panels ranges from $2 to $8. However, it is important to note that this is just a general estimate and the actual cost can differ significantly. It is recommended to contact suppliers or manufacturers directly for accurate pricing information based on specific requirements and customization options. Additionally, installation costs should also be considered, as they can vary depending on the complexity of the project and the labor involved.

- Q: Can FRP roofing panels be used for shopping malls?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for shopping malls. FRP roofing panels are a durable and versatile roofing material that offers several advantages. They are lightweight, making them easier to install and reducing the load on the structure. FRP panels are also weather-resistant, providing excellent protection against UV rays, rain, and extreme temperatures. In the case of shopping malls, FRP roofing panels can be a cost-effective solution as they require minimal maintenance and have a long lifespan. They can be designed to provide natural light transmission, reducing the need for excessive artificial lighting during the day and potentially reducing energy costs. Furthermore, FRP roofing panels are available in a variety of colors and finishes, allowing for customization to match the aesthetic requirements of the shopping mall. They can also be manufactured to provide thermal insulation, which can contribute to energy efficiency and occupant comfort. Overall, FRP roofing panels offer a suitable option for shopping malls due to their durability, weather resistance, cost-effectiveness, and design flexibility.

- Q: Can FRP roofing panels be used for both residential and commercial solar panel installations?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for both residential and commercial solar panel installations. FRP panels are lightweight, durable, and have excellent weather resistance, making them a suitable choice for supporting solar panels on both residential and commercial buildings. They provide a strong base for mounting solar panels, ensuring stability and protection against wind, rain, and other environmental factors. Additionally, FRP panels are cost-effective and can be easily installed, making them a popular choice for solar panel installations in various settings. Whether it is a residential house or a commercial building, FRP roofing panels can provide a reliable and long-lasting solution for supporting solar panels and promoting renewable energy generation.

- Q: Can FRP roofing panels be used for transportation infrastructure?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be used for transportation infrastructure. These panels are lightweight, durable, and corrosion-resistant, making them suitable for various applications such as bus shelters, train platforms, pedestrian bridges, and even road and highway structures. They offer advantages over traditional materials like metal or concrete, including ease of installation, low maintenance requirements, and design flexibility. Additionally, FRP roofing panels can withstand harsh weather conditions and provide excellent insulation properties, making them a viable choice for transportation infrastructure projects.

- Q: Do FRP roofing panels come in different colors and designs?

- Yes, FRP roofing panels come in a wide range of colors and designs. This allows homeowners and businesses to choose options that best suit their aesthetic preferences and match the overall design of their property.

- Q: Can FRP roofing panels be installed on metal roofs?

- FRP roofing panels have the capability to be installed on metal roofs. They possess versatility and can be utilized on different roofing materials, including metal roofs. The installation process may differ based on the specific metal roof and the recommendations of the manufacturer. Typically, it involves securing the FRP panels onto the metal roof using screws or other fasteners. Ensuring proper waterproofing and sealing is crucial to prevent any water leakage. Additionally, checking the load-bearing capacity of the metal roof is essential to guarantee it can support the weight of the FRP panels. By following proper installation procedures and adhering to the manufacturer's guidelines, successful installation of FRP roofing panels on metal roofs can be achieved.

Send your message to us

FRP Roofing Panel - High Quality Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords