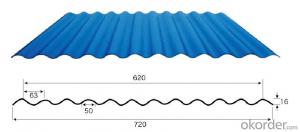

Pp Roofing Sheets

Pp Roofing Sheets Related Searches

Roofing Plywood Sheets House Roof Sheets Pvc Roofing Sheets Price Plastic Coated Steel Roofing Sheets Polycarbonate Sheet Roofing Green Plastic Roofing Sheets Colour Roofing Sheet Frp Roofing Sheets Specification Fitting Polycarbonate Roofing Sheets Coroline Roofing Sheets Clear Perspex Roofing Sheets Pvc Roofing Sheets Price India Buy Roofing Sheets Online Imitation Slate Roofing Sheets Structural Plywood Sheets Pvc Wall Cladding Sheets Corrugated Shed Roof Sheets Fiber Sheet For Roof Fitting Corrugated Plastic Roofing Sheets Roofing Sheets In Chennai Perspex Corrugated Roofing Sheet Expanded Polystyrene Insulation Sheets Heat Resistant Insulation Sheets Clear Corrugated Perspex Roofing Sheets Structural Plastic Sheets Corrugated Felt Roof Sheets Protective Plastic Sheeting Polyurethane Sheet Insulation Roofing Paper Waterproof Redwood Plywood SheetsPp Roofing Sheets Supplier & Manufacturer from China

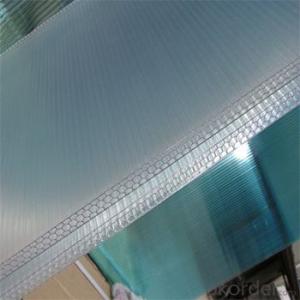

Pp Roofing Sheets are a type of roofing material made from polypropylene, known for their durability, lightweight, and weather-resistant properties. These sheets are designed to provide long-lasting protection and insulation for various types of buildings, such as residential homes, commercial establishments, and industrial facilities. Pp Roofing Sheets offer a cost-effective and efficient solution for roofing needs, as they are easy to install and maintain.Pp Roofing Sheets are widely used in various applications, including but not limited to, agricultural structures, greenhouses, carports, and temporary shelters. Their versatility makes them a popular choice for both new construction projects and as a replacement for existing roofing materials. These sheets are known for their ability to withstand harsh weather conditions, such as heavy rain, snow, and strong winds, while also providing excellent UV protection. This makes Pp Roofing Sheets an ideal choice for regions with extreme weather fluctuations.

Okorder.com is a reputable wholesale supplier of Pp Roofing Sheets, boasting a large inventory to cater to the diverse needs of customers worldwide. The company prides itself on offering high-quality products at competitive prices, ensuring that clients receive the best value for their investment. With a commitment to customer satisfaction, Okorder.com provides excellent support and services to assist clients in selecting the most suitable Pp Roofing Sheets for their specific requirements.

Hot Products