Environmentally FRP Roofing Sheet Making Machine of New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 23 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

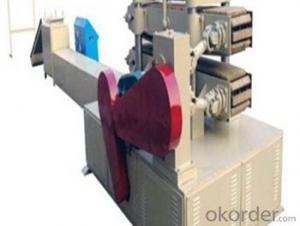

Environmentally FRP Roofing Sheet Making Machine of New Design

Product Description:

This production line can produce lighting sheet, color sheet, common flat sheet, gutter and gel coat sheet.

Product Features:

1.Metering control system and Roving chopper speed can be synchronous with the production line.

2.All the machine parts adopt international standard steel make machine with high stability.

3.System failure can be automatically alarmed and show fault point. Make maintenance easily.

4.Particular parts adopt special purpose wire, durable in use.

5.Size and layout of machine can be made according to customer's requirements.

Product Parameter:

Name | Environmentally FRP Roofing Sheet Making Machine of New Design |

Brand | CMAX |

Weight | 3-8 T |

Dimension(L*W*H) | 6870*1340*1100 |

Power | 4.5KW |

Voltage | 440V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Sheet |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Selectable |

Warranty | 12 Months |

Time of Delivery | 30-45 days |

Product Pictures:

FAQ:

1)Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3)Q: How does your factory do regarding quality control?

A: Quality is priority. we always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications.

5) Q: Can you make the machine according to my design or proto type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

- Q: I am engaged in the plastic processing industry, mainly for ABS and PP through chemical agent for processing, will this be harmful to the body?

- Some large metal washing plants, paper mills, leather factories, food factories, etc., should be used in the use of mechanized operation, reduce manual operation, prevent long time direct contact with the skin. Pregnant women should change jobs appropriately so as not to influence the next generation. The waste water discharged by the factory should be discharged after the sewage treatment has been purified to meet the national discharge standard so as to ensure that our groundwater resources are free from pollution.

- Q: The next 5 to 10 years, small workshops waste plastics processing prospects for development?

- China's plastic machinery industry production enterprises are large, most enterprises seriously deviate from the economic scale, production equipment backward, technical progress difficult situation is still serious. But some enterprises grasp the trend of market demand and technical development, through technical transformation effectively seize market opportunities, develop economic indicators of economic scale backbone enterprises begun to take place before the sort of product sales enterprises accounted for about twice the total domestic plastic machinery sales. So far, China's plastic machinery products are still medium, small as the mainstream, production has been in the world for many years.In 2012, China exported 69297 sets of plastic machinery, with a total amount of 1 billion 618 million 868 thousand US dollars, with an increase of 10.5% over the same period of last year, and the growth rate fell by 17.9% compared with 2011. Imports of plastic machinery 10482 units, total 2 billion 126 million 350 thousand U. S. dollars, the number of imports and the amount of year-on-year decrease, of which the amount of imports decreased by 2.4%. The year 2012 presses trade deficit of $507 million 485 thousand, compared with 2011 deficit significantly reduced.In 2013 the number of China machinery import 10052 units, the amount of imports of about $1 billion 820 million, and last year fell by 4% and 15%; exports, total exports in 2013 China machine 135213 units, the export amount of approximately $1 billion 720 million, an increase of 94% and 7% respectively.In the first half of 2014, China imported 4156 injection molding machines, an increase of 63%, and imports amounted to 398 million 650 thousand U. s.dollars, an increase of 18%.

- Q: How much does it cost to process disposable plastic bags?

- Ruian pine machinery factory production of such machinery is probably 19 to 220 thousand of the way, Taiwan produced more expensive, most of the price is more than 300 thousand bar,

- Q: The processing of plastic bottles

- The production process of plastic bottle has two kinds: the first kind is extrusion blowing process, the plastic raw materials into the extruder, the melting extruding molten parison, then put the bottle mold blow molding, cooling after removed from the mold, eliminating waste edge to be finished after. This process is mainly used to produce polyethylene, PVC plastic bottles, such as milk bottles, soy sauce bottles and so on. The second is the plastic material injection stretch blow molding process, the injection molding machine injection molding tubular billet, then put the bottle mould through stretch blow molding, cooling after the finished product is obtained. This process is mainly used to produce PET plastic bottles, such as mineral water bottles and so on.

- Q: How much profit can a ton earn? Is it difficult to operate the program?

- Do not make money, you see the location of the market demand, the ability to digest and competition with the industry and other aspects, in general even if money is earned a hard-earned money, profit general in 200-500 tons, and raw materials and sales organizations should be guaranteed, otherwise it is difficult to open the market.

- Q: What machines do you need? Where can I get the raw material? Thank you

- Now online can buy, of course, the machine on the spot to look goodCup making machine, bowl making machine, printing press, drawing machine, almost

- Q: The main plastic of plastic products

- Polyethylene plastics (Polyethylene) are polymers of ethylene monomers. The raw material for production is oil, coke oven gas or alcohol. Industrial production of polyethylene usually by ethanol dehydration, acetylene catalytic hydrogenation or high temperature cracking. Its commodity name is abbreviated as "B plastic"; the English abbreviation is "PE". Because the density of polyethylene is different, it is divided into low-density polyethylene.[PE (L)], medium density polyethylene [PE (M)] and high density polyethylene [PE (H)].The molecular formula of polyethylene is: (- CH2, CH2 -) n. It is linear in geometry and theoretically has no branched chain and is prone to crystallization. Usually the polyethylene molecule is composed of crystalline and amorphous state in high elastic interlaced region; crystalline polyethylene plastic gives high hardness, strength, chemical stability; amorphous region with polyethylene plastic higher flexibility, toughness, transparency etc.. In fact, polyethylene macromolecules are not absolutely free of branched chains. Its crystallinity is different, density is different, physical and mechanical properties are also different.

- Q: What kind of machine is needed for the production of plastic products?

- Seventy thousand or eighty thousand an injection molding machine, a crushing machine, a drying machine forty thousand or fifty thousand, workshop, rent, labor, water and electricity to ten thousand months Duoliangwanyi, mold materials, another operator, of course cost large scale is low.

- Q: What kind of equipment does the groove on the PP plastic board work on?

- It can be machined with a shaper or engraving machine

Send your message to us

Environmentally FRP Roofing Sheet Making Machine of New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 23 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords