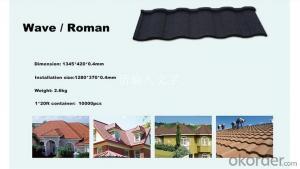

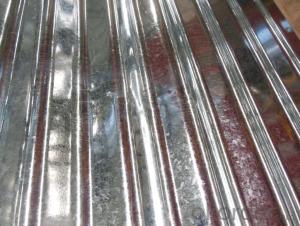

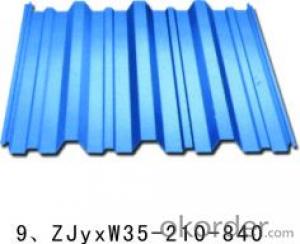

House Roof Sheets

House Roof Sheets Related Searches

Solar Panel On Roof Rack Roof Tile Machine Monier Concrete Roof Tiles House Roof Felt Roof LaggingHot Searches

Fiberglass Scaffolding For Sale Plastic Roof Tiles For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Cost Of Concrete Tile Roof Roof Insulation Price Artificial Slate Roof Tiles Price Ceiling Fan Lowest Price Tesla Solar Roof Inverter Types Of Flat Roof Coverings Stone Wall Tiles Cost Company Office Design Ceramic Roof Tiles Cost Metal Roof Tiles Prices Cement Roof Tile Manufacturers Clay Roof Tile Manufacturers Synthetic Roof Tiles Cost Roof Clay Tiles Prices Interlocking Roof Tiles Prices 30 Year Roof Shingles PricesHouse Roof Sheets Supplier & Manufacturer from China

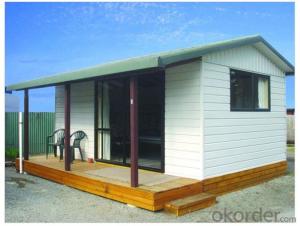

Okorder.com is a professional House Roof Sheets supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest House Roof Sheets firm in China.Hot Products

FAQ

- Fiberglass fabric is widely used in automotive applications due to its excellent properties in handling vibration. When subjected to vibrations, fiberglass fabric has the ability to dampen and absorb the energy, reducing the overall impact and minimizing the transmission of vibrations to other components or passengers in the vehicle. The key factor that allows fiberglass fabric to handle vibrations effectively is its high tensile strength. The fabric's strong and durable nature enables it to withstand the repetitive stress and strain caused by vibrations without experiencing deformation or breakage. This ensures the longevity and reliability of the fiberglass fabric in automotive applications. Additionally, fiberglass fabric has a relatively low density compared to other materials, which further contributes to its ability to handle vibrations. The lightweight nature of the fabric reduces the mass that is subjected to the vibrations, making it less prone to excessive movement or oscillations. This not only improves the overall stability of the vehicle but also reduces the potential for unwanted noise and discomfort caused by vibrations. Moreover, fiberglass fabric possesses excellent thermal and chemical resistance properties, which make it well-suited for automotive environments. It can withstand high temperatures and exposure to various chemicals typical in automotive applications, ensuring its performance remains unaffected over time. In summary, fiberglass fabric effectively handles vibrations in automotive applications by dampening and absorbing the energy, thanks to its high tensile strength and low density. Its ability to withstand repetitive stress and strain, resistance to thermal and chemical degradation, and lightweight nature contribute to its reliability and longevity in minimizing the transmission of vibrations and ensuring a comfortable and stable driving experience.

- Two, fat and PVC paste resin paste into the sizing, coated on glass fiber cloth, so that after baking, how do not shrink?

- The auxiliary plasticizer can be added, and the dissolving capacity of the auxiliary plasticizer is relatively small, and when used, the viscosity is reduced and the storage is favorable.

- Yes, fiberglass fabric can be used for reinforcement in architectural structures. It is a lightweight material that offers high strength and durability, making it suitable for reinforcing concrete, masonry, and other building materials. Fiberglass fabric is commonly used in applications such as wall panels, roofing systems, and composite structures, providing added structural support and enhancing the overall strength and stability of architectural designs.

- Yes, fiberglass fabric can be used for medical devices. It is commonly used in applications such as wound dressings, orthopedic casts, and splints due to its lightweight, high strength, and flexibility. Furthermore, its biocompatible properties make it suitable for medical use as it does not cause any adverse reactions or allergies in patients.

- HVAC systems are well aware of the exceptional performance of fiberglass fabric in extreme temperatures. This material is perfect for insulation because it can endure high temperatures without compromising its structural integrity or insulation properties. When it comes to hot environments, fiberglass fabric acts as a barrier, blocking the transfer of heat between different areas within the HVAC system. It effectively traps heat within the desired space, ensuring energy efficiency and minimizing heat loss. Similarly, in cold temperatures, fiberglass fabric functions as an insulator, preventing heat from escaping and maintaining a consistent temperature within the HVAC system. This reduces energy consumption and ensures optimal performance. Moreover, fiberglass fabric is fire-resistant and does not emit toxic gases when exposed to extreme temperatures. This makes it a safe option for HVAC systems, as it does not contribute to the spread of fires or pose health hazards in case of accidental overheating. Another advantage of fiberglass fabric in extreme temperatures is its durability and long lifespan. It remains intact and unimpaired when subjected to high or low temperatures, making it suitable for prolonged use in HVAC systems. It can withstand the thermal cycling that occurs within the system without compromising its insulation properties or structural integrity. In conclusion, fiberglass fabric is a reliable and efficient material for extreme temperatures in HVAC systems. It offers insulation, energy efficiency, safety, and durability, making it a popular choice for various HVAC applications.

- What about the leaking water made of fiberglass cloth?

- Also, fiberglass cloth is the best choice for good quality, such as glass fiber, glass fiber, wellav stone Sichuan glass fiber and so on, which can be used for a long time.

- Yes, fiberglass fabrics are highly suitable for use in marine environments. Fiberglass is known for its exceptional strength and durability, making it an ideal material for marine applications. It is resistant to corrosion, moisture, and UV rays, which are commonly encountered in marine environments. Fiberglass fabrics also have excellent thermal and electrical insulation properties, further enhancing their suitability for marine use. Moreover, fiberglass fabrics can be easily molded into various shapes and sizes, allowing for flexible and efficient design options in boat building and repair. Overall, the combination of strength, durability, corrosion resistance, and versatility make fiberglass fabrics an excellent choice for marine environments.

- Indeed, filtration applications can make use of fiberglass fabric. Its utilization is prevalent in filtration systems owing to its impressive attributes of robustness, longevity, and chemical resistance. This fabric effectively eradicates particles, impurities, and pollutants from not only air, but also water and other fluids. The dense weaving of fiberglass fabric permits proficient filtration without hindering the smooth flow of air. Furthermore, the maintenance and cleansing of fiberglass fabric pose no difficulty, rendering it suitable for a wide range of filtration applications including air filters, water filters, oil filters, and industrial filtration systems.