High Temperature Graphite Coated Fiberglass Fabric Heat Resistant Glass Cloth with Ptfe Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

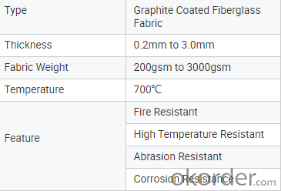

Description: Graphite coated fiberglass Fabric is a unique cloth constructed from base material of fiberglass fabric impregnated with graphite on both sides to increase the temperature resistance capability of the finished product. The coating also improve the performance where flexing is involved. Graphite coated glass cloth is high temperature & corrosion resistant. It also has excellent heat resistance, good abrasion and release properties.

Features: High Temperature And Heat Resistance, Good Abrasion

Application: welding defender, welding blanket ,fire blanket, fire curtain, high temperature, foundry splash protection, heat protection quilts, heat shields, sleeves, connectors and insulation jackets

PRICE: USD7 per square meter

UNIT: square meter

MOQ: 500square meters

Weight: 200gsm-3000gsm or customized

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature: 700℃

Product name: Graphite coated fiberglass fabric

Coating/Finish/Surface Treatment: Graphite coated

Roll length: 50 meter or customized

Color: Black

Weave Type: plain woven

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass fabric, Graphite

Thickness: 0.2mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Graphite coated glass cloth rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Can fiberglass fabric be used for curtains and drapes?

- Certainly, curtains and drapes can be made with fiberglass fabric. This material offers numerous advantages for window treatments. Firstly, fiberglass fabric is renowned for its strength and durability, making it an excellent long-term option for curtains and drapes. It can withstand regular use and is resistant to damage, ensuring that your window coverings will remain in good condition for an extended period. Moreover, fiberglass fabric is commonly treated with a special coating that renders it flame-resistant. This is particularly important for curtains and drapes, especially in areas where fire safety is a concern. The flame-resistant properties of fiberglass fabric provide an additional layer of protection and peace of mind. Furthermore, fiberglass fabric is known for its insulation properties. It can effectively regulate temperature and block unwanted drafts, making it a perfect choice for curtains and drapes in both cold and hot climates. The insulation capabilities of fiberglass fabric contribute to energy efficiency in your home, helping to reduce heating and cooling expenses. Additionally, fiberglass fabric is lightweight and effortless to maintain. It is typically resistant to stains, making it easier to clean and maintain the appearance of your curtains and drapes. Fiberglass fabric also tends to resist fading caused by exposure to sunlight, ensuring that your window coverings will retain their color and vibrancy over time. In conclusion, fiberglass fabric is definitely suitable for curtains and drapes. Its strength, flame-resistant properties, insulation capabilities, and ease of maintenance make it a practical and versatile choice for window treatments.

- Q: Rural cement flat roof room, how to do waterproof, anti leakage best?

- The laying of the rigid waterproof layer, should be completed in the first flexible waterproof layer after two days of construction, mainly in high fatty acid waterproofing agent, cement mortar, sand, fine aggregate, fiber as basic material, waterproof layer thickness is 20-30 mm;(1) install the grid batten according to the specification, and set it to 4000 millimeters * 4000 millimeters. Then sprinkle water to make the base surface moist, but no water;According to (2), from far to near, from high to low order, the mortar prepared fine stone concrete or by grid construction, with a lattice a complete, smooth compaction;(3) after the initial setting, remove the partition bar, press and trim the partition joint;(4), using the flexible sealing material filling dividing joint, surface treatment. After completion of construction, pay attention to sprinkler maintenance;(5) if there is roof planting soil, it should be covered with planting soil in as short as possible time.

- Q: How to use silica gel cloth and glue?

- The former is nylon, glass fiber and other materials on the coating of liquid silicone rubber, and its bonding can be used at room temperature, slow dry glue

- Q: How is fiberglass fabric cut and shaped?

- Fiberglass fabric can be cut and shaped using various methods such as scissors, utility knives, or rotary cutters. The fabric can be easily trimmed or shaped according to specific dimensions or patterns.

- Q: Can fiberglass fabric be used for fire protection?

- Yes, fiberglass fabric can be used for fire protection. It has excellent fire-resistant properties and is often used in various industries, such as construction and manufacturing, to provide thermal insulation and prevent the spread of flames.

- Q: How does fiberglass fabric perform in vibration isolation applications?

- The excellent performance of fiberglass fabric in vibration isolation applications is well-known. This material possesses inherent properties, including high tensile strength, flexibility, and low thermal conductivity, which make it perfect for effectively isolating vibrations. When exposed to vibrations, fiberglass fabric absorbs and dampens the resulting energy, thereby reducing the transmission of vibrations from one component to another. This ability to absorb vibrations is crucial in industries such as automotive, aerospace, and construction, where minimizing vibrations is vital for optimal performance and safety. Additionally, the high tensile strength of fiberglass fabric ensures that it can withstand the forces and stresses associated with vibrations without tearing or breaking. This strength is important for maintaining the fabric's integrity and effectiveness as a vibration isolator since any damage to the fabric could compromise its performance. Furthermore, the flexibility of fiberglass fabric allows it to conform to various shapes and surfaces, ensuring a secure and snug fit in vibration isolation applications. This flexibility enables the fabric to effectively isolate vibrations across a wide range of frequencies and amplitudes, making it a versatile solution for different vibration control needs. Lastly, the low thermal conductivity of fiberglass fabric is advantageous in vibration isolation applications where temperature differences exist. By minimizing heat transfer, the fabric helps maintain the stability and performance of isolated components, especially in environments with extreme temperatures. In conclusion, fiberglass fabric is highly effective in vibration isolation applications due to its ability to absorb and dampen vibrations, high tensile strength, flexibility, and low thermal conductivity. Its effectiveness, versatility, and durability make it the preferred choice for industries that require efficient vibration control.

- Q: Is fiberglass fabric resistant to moisture absorption?

- Yes, fiberglass fabric is highly resistant to moisture absorption.

- Q: Can fiberglass fabric be used for making sports jerseys?

- Sports jerseys can be made using fiberglass fabric, although it is not commonly used for this purpose. Fiberglass fabric has certain advantages that may be desirable for specific sports applications. It is known for being durable, strong, and resistant to wear and tear. These qualities make it suitable for sports that involve intense physical contact or rough playing conditions. Furthermore, fiberglass fabric has excellent moisture-wicking properties, which can help athletes stay dry and comfortable during intense physical activity. However, it is important to note that fiberglass fabric may not offer the same level of breathability or flexibility as traditional sports jersey materials like polyester or nylon. It is also heavier and may restrict range of motion. Therefore, the use of fiberglass fabric for sports jerseys would likely be limited to specific sports or situations where its unique properties are beneficial.

- Q: Is fiberglass fabric resistant to chemicals in industrial settings?

- In industrial settings, fiberglass fabric is generally resistant to chemicals. This fabric is made from fine glass fibers, which give it excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. As a result, it is suitable for use in industries where workers come into contact with various chemicals, such as chemical processing, petrochemical, and pharmaceutical industries. Additionally, fiberglass fabric is well-known for its ability to withstand high temperatures and its flame retardant properties, making it even more suitable for industrial environments. However, it is important to note that the resistance of fiberglass fabric to chemicals may vary depending on the specific type and concentration of the chemical. Therefore, it is always recommended to consult the manufacturer's specifications or conduct compatibility tests before using fiberglass fabric in a particular industrial application.

- Q: Can fiberglass fabric be used for insulation sheets?

- Yes, fiberglass fabric can be used for insulation sheets.

Send your message to us

High Temperature Graphite Coated Fiberglass Fabric Heat Resistant Glass Cloth with Ptfe Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords