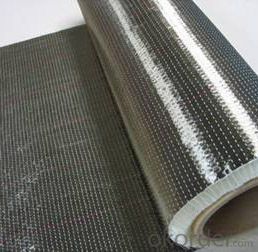

Carbon Fiber Fiberglass Release Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

With raw material of carbon fiber yarn from Toray or Mitsubishi Japan , our company can produce both woven fabric and knitted fabric, including unidirectional fabrics, plain weave fabric, twill fabric, satin fabric and multi-axial fabrics. The main use of carbon fabric is to make structural materials reinforced with resin, metal, and ceramic etc. Among the existing structural materials, carbon fiber reinforced epoxy resin composites have the highest specific strength and modulus. In the areas of strict requirements on density, stiffness, weight, fatigue characteristics, high temperature and high chemical stability, CFRP have an outstanding advantage.

Product Features:

● Light weight

● Products high strength, high modulus

● Superior acid corrosion resistance

Product Specifications:

Density:100-400g/m2.

Item:1k,2k,3k,6k,12k.

Weave:Plain,Twill,Satin,Multiaxial,UD。

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 225mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: How does fiberglass fabric perform in extreme temperatures?

- Fiberglass fabric is known for its exceptional performance in extreme temperatures. This type of fabric is highly resistant to heat and can withstand very high temperatures without melting or deforming. Fiberglass has a high melting point, typically around 1,200 to 1,400 degrees Celsius (2,192 to 2,552 degrees Fahrenheit), which allows it to perform well in extreme heat conditions. Moreover, fiberglass fabric also performs remarkably in low temperatures. It retains its strength and structural integrity even in freezing temperatures, making it suitable for various applications in cold environments. This characteristic makes fiberglass fabric a popular choice for industries such as aerospace, automotive, and construction, where materials need to withstand extreme temperature variations. Additionally, fiberglass fabric has excellent thermal insulation properties, which means it can effectively resist the transfer of heat. This property makes it an ideal material for applications that require insulation against high or low temperatures, such as in thermal blankets, insulation panels, and protective clothing. Overall, fiberglass fabric's ability to perform in extreme temperatures is one of its key advantages. Its high heat resistance, low-temperature durability, and thermal insulation properties make it a reliable and versatile material for a wide range of applications in both hot and cold environments.

- Q: Can fiberglass fabric be used for curtains and drapes?

- Yes, fiberglass fabric can be used for curtains and drapes. It is a versatile material that offers durability, resistance to fire, and is lightweight. Additionally, fiberglass fabric can provide privacy while allowing natural light to filter through.

- Q: What are the different fiberglass fabric finishes for abrasion resistance?

- There are several different fiberglass fabric finishes that are specifically designed to enhance abrasion resistance. These finishes are applied to the fabric during the manufacturing process and serve to improve the fabric's durability and resistance to wear and tear. One commonly used fiberglass fabric finish for abrasion resistance is a silicone coating. This coating forms a protective layer on the fabric's surface, making it more resistant to abrasion and ensuring a longer lifespan. Silicone-coated fiberglass fabrics are often used in applications where high levels of abrasion are expected, such as conveyor belts and industrial curtains. Another popular finish for abrasion resistance is a PVC coating. This type of coating provides a strong barrier against friction and wear, making the fabric more resistant to tears, punctures, and other forms of damage. PVC-coated fiberglass fabrics are commonly used in applications such as protective clothing, tents, and covers for machinery and equipment. In addition to silicone and PVC coatings, there are also other finishes available for enhancing abrasion resistance in fiberglass fabrics. For example, some fabrics may be treated with a polyurethane coating, which provides similar benefits to silicone and PVC coatings. Other finishes may include chemical treatments or laminations that offer improved abrasion resistance. Ultimately, the choice of fiberglass fabric finish for abrasion resistance will depend on the specific application and the level of protection required. Manufacturers and users of fiberglass fabrics should carefully consider the intended use and the potential wear and tear that the fabric may encounter in order to select the most appropriate finish for their needs.

- Q: Can fiberglass fabric be used for heat-resistant curtains?

- Yes, fiberglass fabric can be used for heat-resistant curtains. Fiberglass is known for its excellent heat resistance properties, making it suitable for applications where high temperatures are present. Using fiberglass fabric as a material for heat-resistant curtains can provide insulation and protection against heat, making it a suitable choice for such applications.

- Q: Can fiberglass fabric be used for making protective covers?

- Fiberglass fabric has the ability to be used in the creation of protective covers. This material is widely recognized for its exceptional strength and durability, making it an ideal choice for safeguarding against a multitude of elements, including heat, chemicals, and abrasions. Its fire-resistant nature and resistance to melting make it particularly suitable for situations where fire safety is of utmost importance. Additionally, fiberglass fabric is lightweight and flexible, allowing for effortless handling and installation. It can be utilized to construct protective covers for a diverse range of items, such as equipment, machinery, vehicles, as well as personal protective gear like gloves and aprons. In summary, fiberglass fabric is highly regarded for its superior protective properties and is extensively utilized across various industries for the production of protective covers.

- Q: How does fiberglass fabric perform in impact resistance?

- Fiberglass fabric is known for its excellent impact resistance properties. Due to its composition of interwoven glass fibers, it is able to absorb and distribute impact energy efficiently, making it highly resistant to damage from impacts or collisions. The inherent strength and rigidity of the glass fibers provide a solid barrier against external forces, preventing cracks, fractures, or breakage. Additionally, the flexibility of the fabric allows it to conform to different shapes, further enhancing its impact resistance capabilities. This makes fiberglass fabric ideal for applications that require protection against impacts, such as in the automotive, aerospace, and construction industries.

- Q: Can fiberglass fabric be laminated with other materials?

- Yes, fiberglass fabric can be laminated with other materials. Laminating refers to the process of bonding two or more layers of material together to create a composite material with enhanced properties. Fiberglass fabric is often used as a reinforcement material in laminates, providing strength and durability. It can be laminated with various materials such as resins, plastics, metals, and other fabrics to create composite structures with specific characteristics. The lamination process typically involves applying a layer of adhesive or resin onto the fiberglass fabric and then bonding it with the desired material. This allows for the creation of versatile and customizable materials that can be used in a wide range of applications such as aerospace, automotive, construction, and marine industries.

- Q: Difference between glass fiber felt and glass fiber cloth

- Glass fiber mesh is a kind of glass fiber cloth.

- Q: How is fiberglass fabric used in the production of thermal curtains?

- Fiberglass fabric is used in the production of thermal curtains as it possesses excellent insulating properties. It is often incorporated as a lining or layer within the curtain to increase its thermal efficiency. The fiberglass fabric helps to trap air pockets, preventing heat transfer between the inside and outside of the room. This insulation feature helps to keep the room warm in winters and cool in summers, making it an ideal choice for thermal curtains.

- Q: Can fiberglass fabric be used for car covers?

- Car covers can indeed make use of fiberglass fabric. This type of fabric is recognized for its strength and resistance to tearing, making it ideal for safeguarding cars against dust, dirt, and UV rays. Moreover, it's a lightweight material that is easy to work with and can be easily tailored to fit various car sizes and shapes. Another advantage of fiberglass fabric is its remarkable ability to insulate against heat, thereby shielding the car's interior from extreme temperatures. However, it's worth mentioning that fiberglass fabric itself may not be waterproof, so it is advisable to apply a waterproof coating or layer beneath the fabric to provide additional protection against rain and moisture.

Send your message to us

Carbon Fiber Fiberglass Release Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords