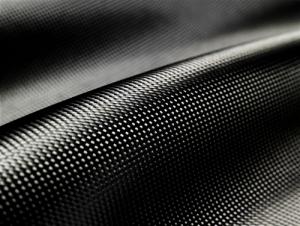

Carbon Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Carbon Fiber Fabric

Smooth and equally Carbon fiber fabric / ClotSize:1K,3K,6K,12K

Weight:100g/sqm~640g/sqm Weave:plain/twill/satin

General Data of Carbon Fiber Fabric

|

Tow Size |

Tow Count/CM |

Weave Style |

WidthRange (mm) |

Std. Width (mm) |

Thickness (mm) |

FAW (g/sq.m) |

FAW (oz/sq.yd) |

|

3K |

4 x 4 |

Plain |

10~1500 |

1000 |

0.16 |

160 |

4.72 |

|

3K |

4 x 4 |

2x2 Twill |

10~1500 |

1000 |

0.16 |

160 |

4.72 |

|

3K |

5 x 4 |

Plain |

10~1500 |

1000 |

0.18 |

180 |

5.31 |

|

3K |

5 x 4 |

2x2 Twill |

10~1500 |

1000 |

0.18 |

180 |

5.31 |

|

3K |

5 x 5 |

Plain |

10~1500 |

1000 |

0.2 |

200 |

5.90 |

|

3K |

5 x 5 |

2x2 Twill |

10~1500 |

1000 |

0.2 |

200 |

5.90 |

|

3K |

5 x 6 |

Plain |

10~1500 |

1000 |

0.22 |

220 |

6.49 |

|

3K |

5 x 6 |

2x2 Twill |

10~1500 |

1000 |

0.22 |

220 |

6.49 |

|

3K |

6 x 6 |

Plain |

10~1500 |

1000 |

0.24 |

240 |

7.08 |

|

3K |

6 x 6 |

2x2 Twill |

10~1500 |

1000 |

0.24 |

240 |

7.08 |

|

3K |

8 x 8 |

Plain |

10~1500 |

1000 |

0.32 |

320 |

9.44 |

|

3K |

8 x 8 |

2x2 Twill |

10~1500 |

1000 |

0.32 |

320 |

9.44 |

|

3K |

8 x 8 |

8H Satin |

10~1500 |

1000 |

0.32 |

320 |

9.44 |

Storage of Carbon Fiber Fabric

It is recommended that the carbon fiber fabric are stored in a cool and dry environment. Recommended temperature range of storage is between 10 ~ 30 degree and relative humidity between 50 ~ 75%.The carbon fiber fabric should remain in the packaging until just prior to use.

Packaging & Delivery of Carbon Fiber Fabric

Product is manufactured in form of a roll wound on a paper tube and then packed in a plastic film and placed within a cardboard carton. Rolls can be loaded into a container directly or on pallets.

Packaging Detail: carton

Delivery Detail: within 20 days

- Q: How is carbon used in the production of ceramics?

- Carbon is used in the production of ceramics as a key component in the creation of carbon-based materials, such as carbon fibers or carbon nanotubes, which can be incorporated into ceramic matrices to enhance their mechanical properties, electrical conductivity, and thermal stability. Additionally, carbon can also be utilized as a reducing agent in certain ceramic processes, such as the production of silicon carbide, where it reacts with oxygen to remove impurities and stabilize the ceramic structure.

- Q: Yes, I have a weapon, want to strengthen 11, said to be advanced furnace rock carbon, do not know how to get, look at the prawns pointing

- Pro, tell you an unfortunate news, out of the eighty furnace rock carbon, old horse recycling, burning their own boilers, and now we strengthen the use of colorless small crystal block, that is, the colorless small crystal block instead of the original furnace rock carbon.

- Q: How to identify a laptop shell is carbon fiber

- Carbon fiber, as its name suggests, is made from carbon fiber, so there are several characteristics. First, if it is not colored, you can see the obvious fiber. Second is black carbon color. And it's a lot more than ABS.

- Q: How does carbon impact the pH balance of oceans?

- Carbon dioxide (CO2) released into the atmosphere is absorbed by the oceans, leading to a process called ocean acidification. When CO2 dissolves in seawater, it reacts with water to form carbonic acid, which then releases hydrogen ions, increasing the acidity of the water. This increase in acidity disrupts the pH balance of the oceans, making them more acidic. The increased acidity has numerous negative impacts on marine life and ecosystems. Many marine organisms, such as coral reefs, shellfish, and phytoplankton, rely on calcium carbonate to build their shells and skeletons. However, in more acidic waters, calcium carbonate becomes scarcer, making it harder for these organisms to maintain their structures. This can lead to weakened shells, reduced growth, and even death. Ocean acidification also affects the reproductive and physiological processes of marine organisms. For example, it can interfere with the development of fish larvae and disrupt the ability of some species to detect predators or find food. Additionally, the increased acidity can also harm the organisms that depend on these species for food, creating a ripple effect throughout the food chain. Furthermore, ocean acidification can impact the overall health and functioning of marine ecosystems. Coral reefs, often referred to as the "rainforests of the sea," provide habitats for a vast array of marine species. As the acidity of the oceans increases, coral reefs become more vulnerable and are at greater risk of bleaching and ultimately dying off. This loss of coral reefs would have devastating consequences for the biodiversity and productivity of marine ecosystems. In conclusion, the increase in carbon dioxide levels in the atmosphere leads to the absorption of CO2 by the oceans, resulting in ocean acidification. This process disrupts the pH balance of the oceans, making them more acidic. The increased acidity has detrimental effects on marine life, including the ability of organisms to build shells, reproduce, and function within their ecosystems. Addressing the issue of carbon emissions is crucial to mitigating the negative impacts of carbon on the pH balance of oceans and preserving the health and integrity of marine ecosystems.

- Q: How can carbon capture and storage be implemented?

- Carbon capture and storage (CCS) is a technology that involves capturing carbon dioxide (CO2) emissions from industrial processes and storing them underground, preventing their release into the atmosphere. Implementing CCS involves several key steps. Firstly, the capture process involves capturing CO2 emissions from power plants, factories, and other industrial sources. This can be achieved through various methods, such as pre-combustion capture, post-combustion capture, and oxy-fuel combustion. Pre-combustion capture involves converting fossil fuels into a mixture of hydrogen and CO2, with the latter separated and stored. Post-combustion capture involves removing CO2 from the flue gases after combustion. Oxy-fuel combustion involves burning fossil fuels in pure oxygen, resulting in a flue gas that is mostly CO2. Once captured, the second step is transportation. The captured CO2 needs to be transported from the capture site to a storage site. This transportation can be done through pipelines, ships, or trucks, depending on the distance and volume of CO2. Pipelines are the most common method, especially for large-scale projects, as they are cost-effective and efficient. The third step is storage, which involves injecting the captured CO2 deep underground into geological formations for long-term storage. The most suitable storage sites are depleted oil and gas fields, saline aquifers, and deep coal seams. These sites have the capacity to securely store large amounts of CO2 for hundreds or even thousands of years. To ensure the safety and effectiveness of CCS, monitoring and verification play a crucial role. Continuous monitoring is required to detect any potential leaks or seismic activities that may compromise the integrity of the storage site. Verification activities involve assessing the long-term storage of CO2 and ensuring compliance with regulations and standards. Implementing CCS also requires policy support and financial incentives. Governments can provide regulatory frameworks, tax incentives, and funding to encourage the adoption of CCS technologies. International cooperation and collaboration are also important, as CCS can be a global solution to mitigate climate change. In conclusion, implementing carbon capture and storage involves capturing CO2 emissions, transporting them to a storage site, injecting them underground, and monitoring the storage process. It requires various technologies, infrastructure, and policy support to achieve widespread adoption. By effectively implementing CCS, we can significantly reduce greenhouse gas emissions and combat climate change.

- Q: Paint paint fluorocarbon paint which expensive?

- Paint is divided into two categories, a class of low temperature baking paint, curing temperature of 140 degrees -180 degrees, and the other category is called high temperature baking paint, its curing temperature is 280 degrees -400 degrees.High temperature baking also known as Teflon (Teflon) English called Polytetrafluoroetylene, referred to as Teflon, PTFE and F4. High performance special Teflon coating is fluorine coating resin with polytetrafluoroethylene, English name for Teflon, because the pronunciation of reason, commonly known as Teflon, Tie Fulong, Teflon, Teflon and so on (all Teflon transliteration).

- Q: What is carbon nanocomposite coating?

- Carbon nanocomposite coating is a type of protective coating that is made using carbon nanotubes or other carbon-based nanoparticles. These nanoparticles are dispersed within a matrix material, such as polymer or metal, to create a thin film that can be applied onto various surfaces. The main purpose of carbon nanocomposite coatings is to enhance the mechanical, thermal, and electrical properties of the coated material. The addition of carbon nanoparticles improves the strength, hardness, and wear resistance of the coating, making it more durable and long-lasting. It also provides excellent corrosion resistance, making it suitable for applications in harsh environments. One of the key advantages of carbon nanocomposite coatings is their ability to provide multifunctional properties. For example, they can be engineered to have high electrical conductivity, which makes them ideal for applications in electronics and electrochemical devices. Additionally, they can have high thermal conductivity, making them useful for heat dissipation in electronic devices or as a thermal barrier coating. Moreover, carbon nanocomposite coatings have shown promising results in various fields such as aerospace, automotive, energy, and healthcare. In aerospace, they can be used to improve the performance and durability of aircraft components, while in the automotive industry, they can provide anti-scratch and self-cleaning properties. In energy applications, they can be utilized to enhance the efficiency of solar panels or to prevent corrosion in oil and gas pipelines. Additionally, in healthcare, they can be used for drug delivery, as antibacterial coatings, or for bio-sensing applications. Overall, carbon nanocomposite coatings offer a wide range of benefits, including improved mechanical and electrical properties, corrosion resistance, and multifunctionality. With ongoing research and development, these coatings hold great promise for various industries, providing innovative solutions to address their specific needs and challenges.

- Q: How are carbon nanotubes used in various industries?

- Carbon nanotubes are used in various industries for their exceptional properties. In electronics, they are utilized for creating smaller and faster transistors and memory devices. In materials science, they enhance the strength and conductivity of composites used in aerospace and automotive sectors. They also find applications in energy storage, where they improve the efficiency of batteries and supercapacitors. Additionally, carbon nanotubes are employed in medicine for drug delivery systems and as biosensors for detecting diseases. Overall, their versatility makes them valuable in multiple industries for enhancing performance and enabling innovative technologies.

- Q: What is carbon neutral construction?

- Carbon neutral construction entails a sustainable approach to constructing and designing structures that aims to minimize or counterbalance the amount of carbon emissions generated during the construction process. The objective is to achieve equilibrium between the carbon emissions released into the atmosphere and those that are eliminated or offset through various measures. To accomplish carbon neutrality in construction, several strategies can be employed. Firstly, the implementation of energy-efficient design principles helps reduce the overall energy consumption of the building. This includes incorporating insulation, efficient HVAC systems, and energy-saving appliances and lighting. In addition, sustainable building materials are utilized, such as recycled materials or those with a minimal carbon footprint. This decreases the energy required for material production and transportation, thus minimizing carbon emissions. Moreover, renewable energy sources are integrated into the construction process. This may involve the installation of solar panels, wind turbines, or geothermal systems to generate clean energy for the building's operations. By reducing reliance on fossil fuels, carbon emissions associated with energy consumption are significantly decreased. Carbon offsetting is another crucial element of carbon neutral construction. This entails investing in projects or initiatives that reduce or eliminate greenhouse gas emissions elsewhere, thereby compensating for the emissions produced during construction. Examples of carbon offsetting activities include reforestation projects, investment in renewable energy initiatives, or support for methane capture programs. Ultimately, carbon neutral construction aims to minimize the environmental impact of building construction and operation by reducing carbon emissions throughout the entire lifespan of the building. By adopting energy-efficient design principles, utilizing sustainable materials, integrating renewable energy sources, and offsetting carbon emissions, carbon neutral construction contributes to the mitigation of climate change and the creation of a more sustainable future.

- Q: Carbon steel with carbon steel, carbon steel yuan yuan is the same? The trouble to know the answer urgently

- For Fang Gang, bar, angle steel, steel, steel wire and other types. According to the shape of carbon structure round is carbon steel round. Especially carbon steel is often said in the past round. Such as 45# round steel. Carbon steel and carbon circle is not necessarily a variety.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | |

| Main Markets | Europe, America, Africa, Oceania and Japan, Korea, southeast Asia |

| Company Certifications | ISO9000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords