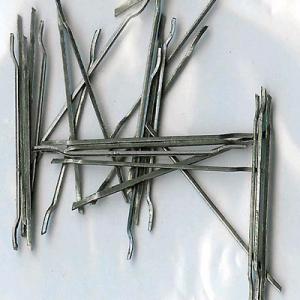

Carbon Steel Fiber

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 50000000 Ton Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Carbon Steel Fiber:

Slit sheet carbon steel fiber is used as a replacement for traditional reinforcement in various concrete applications. With slitsheet steel fibers you can limit micro-cracking, expect excellent concrete strength and lower cost

APPLICATION of Carbon Steel Fiber:

Tunnel

Burst against construction

Gutter of Mining Mountain

Industrial ground

Precast and civil construction

ADVANTAGE of Carbon Steel Fiber:

---Anti-crack,

---Pressure-resistance

---Anti-abrasion

---Bending toughness

SPECIFICATION of Carbon Steel Fiber:

Slit sheet carbon steel fiber |

|

Length (mm) | 10-60 |

Thickness (mm) | 0.5-0.8 |

Width (mm) | 0.5-1 |

Tensile strength (Mpa) | ≥600 |

Packing | 20kgor 25kg / bag |

- Q: Is it gypsum ?

- gypsum is a construction mineral, it is what makes up wall board which is used in most homes and offices buildings. but it is not a part of cement. portland cement is made from Limestone and Clay minerals. Those are heated together to make a cllinker that is further refined to make the product that goes into bags of cement.

- Q: I have a large basement with cement floor and walls. I want to convert it into a game room, for a pool table, foosball, etc. What is the best thing to do with the walls? I think I want to paint them and possibly do some stencil work of sports logos, etc. (Don't really want to use drywall, etc as it CAN get mildly damp down there when we have local flooding) What is the most durable paint that can be used on cement that comes in colors that would work in a game room?

- The First Step with walls that get damp or are prone to flooding is a CMU waterproofing on the walls. It is expensive to do about 80$ for a 5 gallon can and may require two coats but it is worth it. Reason: This will reduce dampness and will allow for a better bond of latex paints. Concrete latex paints will peel with the first signs of dampness. I know tried the same thing and it didn't didn't work. I had to buy the waterproofing and all new paint. So save your self the trouble of repainting buy doing it right the first time.

- Q: I saw bags of concrete bags of cement in Home Depot. What's the difference?

- I think for me I could do less for my kids. I think they could be more independent if I didn't hinder it by doing so much for them rather than expecting them to do more for themselves. Don't get me wrong, they have chores and plenty of responsibilities but I do a lot of things for them that they are probably old enough to do for themselves as well. I guess I mother them too much.

- Q: As there are many types of cement, i want basic types of cement

- Type 1 - Normal portland cement. Type 1 is a general use cement. Type 2 - Is used for structures in water or soil containing moderate amounts of sulfate, or when heat build-up is a concern. Type 3 - High early strength. Used when high strength are desired at very early periods. Type 4 - Low heat portland cement. Used where the amount and rate of heat generation must be kept to a minimum. Type 5 - Sulfate resistant portland cement. Used where the water or soil is high in alkali.

- Q: It has four cement walls but the bad thing is there is a water pump in the pit, so area is limited inside, like an area 5X5, and it has the floor of the house as it's quot;coverquot;.

- No it is not to be safe in a cement well because the wind can be funneled in the well and you will die for sure if any debris gets down there.

- Q: What is rubber cement and where can i get it?

- such as potential of abuse as inhalants and fire. For this reason, as with any adhesive, rubber cement should be used in a well-ventilated area, and care must be taken to avoid heat sources as n-heptane and n-hexane are highly flammable. Rubber cement based on n-heptane is very popular and ubiquitous in the United States, but is generally unknown and unavailable as a consumer product in the UK and some parts of Europe, possibly due to the severe fire hazard of that formulation. A similar solvent based product called Cow Gum was common in the UK, but is no longer in production. Current solvent based options include Marabu-Fixogum and Platignum Studio Gum which are marketed in the UK and Europe. Copydex, a common latex adhesive in the UK, uses an ammonia and water solvent and needs no special handling, making it very child-friendly. While for this reason it is often given to children, it is also used in artwork, and finds widespread use in light D.I.Y. work such as fixing carpet tiles and repairing upholstery

- Q: my dad took the vinyl tile off our garageand he wants to spread cement over the garage floorwhat type of cement would stick to the floor as well as tile glue so the cement would stck forever

- You should really try to get that glue up. The problem is going to be if it's like a mastic (soft and sticky) because that going to take a chemical stripper like Xylene or at least lacquer thinner. Go airflow and at least a half mask with chemical cartridges are necessary. A full mask and personal air supply is really a much better way to go. What ever you put down over that tile adhesive is only going to be as good as that tile adhesive. If you try to put down something hard and brittle like a thin layered cement (Sakrete's Top Bond) now you have something brittle over something soft what do you think is going to happen? You could try putting something soft over it like a urethane rubber but again if the old adhesive fails you spent a lot of time money on Urethane. If the heavy adhesive is off you can try renting a diamond grinder but you have to be careful these are not toys and you can do more damage than good if you don't think you can run it properly... Your cheapest way out may be to just put more tile down. If you like send my some pictures of the floor and I'll try to help... This is my profession.

- Q: Need to remove cement like glue from painted metal. Any house hold items i can use or do i have to buy a glue remover. i.e. rubbing alcohol , cleaners ect. Thanks

- You cant do that because cemert dries really hard so if you jack hammer i suggust not to do because it drys really hard

- Q: I was biking and i fell for my bike we went to the emergency then they put a cast on me after a day i have my surgery they put screw on it because my fibula was displace. after 2 weeks i was so bored cause i cant do anything i try to step on it and it doesnt hurt anymore. next week they will put a cement on me and they will remove it after 4 weeks.

- What cement? Just tell your doctor that you also have a medical degree and can decide for yourself what kind of treatment you need and for how long. Be sure to tell the doctor to his face, and NOT in writing. Because if you write it down, he will KNOW, for sure that you can't write beyond a third grade level and probably DON'T have a medical degree.

- Q: There is water that seeps in when it rains hard near a pipe where the city water comes in. I already tried to use quot;Great Stuffquot; around the pipe and it didn't work. Do I just put hydraulic cement in the area around the pipe area, or do I have to do the whole wall? (Can you tell I'm a new homeowner?)

- To answer the question with certainty a few details may be needed--- where the water line comes in how many feet below grade is it-- if close to grade then re-grading the property around the water pipe may solve the problem-- re-grading away from the house will cause the rainwater to flow away from the house wall--if it is say more than 4 feet below grade-- using hydraulic cement from the inside may be a temporary fix but the outside water pressure will force it out of the crack/hole after 1-2 years depending on how severe your cold/frost cycles are in your neck of the woods-- most water mains that I have seen come up through the floor of most homes--if you are certain the water line entry is leaking dig down from the outside to said water line and apply the cement-a rubber membrane- some tar product--like roofing material sealer and another rubber membrane-- best of luck--

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Carbon Steel Fiber

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 50000000 Ton Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords