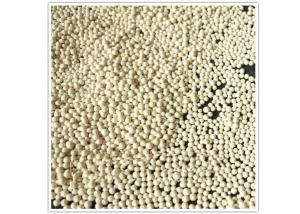

Highest quality for Portland cement 42.5

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PORTLAND CEMENT

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Application

CNBM Cement can be used for all types of architectural or structural concrete construction. Such application as pre-cast panels and systems, cast-in-place, masonry units, tilt-up panel systems, roofing tiles, terrazzo floors, highway median barriers, tile grout, swimming pools, stucco, culture stone,colored masonry products, cement paints and coatings, and ornamental precast concrete items.

CNBM INTERNATIONAL CORPORATION (short for the Company) is a subsidiary of China National Building Material Group Co., Ltd. (short of CNBM Group). China National Building Material Group is a state owned enterprise under directly management of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked 187 in the world's top 500 in 2019. China National Building Materials Group is the world's largest comprehensive building materials industry group, the world's leading new material developer and comprehensive service provider, and has the strongest scientific research strength in the field of building materials and non-metal new materials. CNBM INTERNATIONAL CORPORATION is a brand-new platform built by China National Building Materials Group that focuses on non-metallic materials trading.

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: I am makeing a model rocket ship and it requires Plastic cement and i dont have any will it still work?..

- no..water based glue will not hold like cement. (hence the name...)

- Q: i would like to know how the cement grade be checked? kindly let me know what other test can be done to know the quality of cement?

- There is a physical property called the fineness modulus: But is does apply to cement because cement is a too fine powder. Typically for fine aggregates in concrete, the fineness modulus should be between 2.3 and 3.11. The FM is obtained by adding the cumulative weight percentages retained on the no. 4 sieve, no. 8, no. 16, no. 30, no. 50, and no. 100, and dividing the sum by 100. You can also check what ASTM C-150 says about portland cement.

- Q: I was told to measure sand and cement to get the right mix for 4-1, rather than by volume, how do you weigh it? And am mixing by shovel for 10cm wide by 10 metres by 8cm thick, so was told to mix it all up together at one time rather than doing it every 30 mins. I have a small plastic container to mix, what else should I use to mix on?Do i use sharp sand and cement or plasterers sand, a builder told me plasterers sand

- I use a wheel barrow to mix my concrete and a hoe to mix in the water. It works better then a shovel. A ratio by volume is not hard to measure. Just put in four times the amount of builders sand that you will use in cement. A plastic container will do if it is large enough.

- Q: The house was built in 1925 without foundation tile, over the years whatever was painted over the brick interior walls has bubbled because of the moisture that would have been diverted by an appropriate ditch around the foundation, or tiles to drain it, etc. Several of these bubbles are basketball in size, and there are cracks in many areas of the stucco-like stuff that chips off in large pieces. I want to patch it up, and repaint, what is that stuff called? It looks like cement when chipped off, is it joint compound? How should I go about this? Moisture problems have been aleviated, now I just need to fix the cosmetics.

- When you've got any moisture you desire a moisture sealer. If not that's even higher, makes it lot easier. Prime with zinnser primer tinted virtually the color of your paint. Then comply with with a LATEX PAINT making use of a thick nap curler. If you wish to make it ornamental, buy a sponge curler and use a second colour and position over most effective the skin of the block. It appears rather first-class and dresses it up alot. Good success!! You should utilize a latex paint. I painted block wall in basement that was once getting some moisture, and did use zinnser primer adopted with the aid of latex about 10 years ago and it looks as good in these days as the day I painted it!! So i do know for fact it can be performed.

- Q: As in many modern houses, our en-suite shower is made up of tiles fixed onto plaster board. Over the years this has started to leak as the grouting failed, and the plaster board has become soggy and needs replacing. We have had two suggestions from different builders. One suggests ripping out the old plaster board and replacing it with quot;cement boardquot; onto which tiles would be stuck. The other suggestion involves cutting out the old plaster board, replacing it with new plaster board which would then be quot;sealedquot; before tiles are stuck onto it. Does anyone know which of these would be the better option please? Costs of both proposals appear to be similar so we really want the better engineering solution.

- I run a construction company. We swear by cement board and don't even use plaster board anymore. attached is a partial article on why green board is being phased out: Contractors take note: “greenboard” is being drummed out of the tile industry as a ceramic tile substrate in wet areas. Though traditional greenboard has a moisture-resistant gypsum core and moisture-resistant paper facings, over the years more durable, water-resistant products have been developed that perform better and ensure fewer water-related failures. In fact, Kieren Corcoran, national product manager for Georgia-Pacific Corp. noted the 2006 International Residential Code (IRC) further accelerates the trend away from greenboard stating, “Water-resistant gypsum backing board [greenboard] shall not be used where there will be direct exposure to water.” (Section R702.3.8.1) The 2006 IRC goes on to say that “Cement, fiber cement or glass mat gypsum backers in compliance with ASTM C1288, C1325 or C1178 and installed in accordance with manufacturer’s recommendations shall be used as backers for wall tile in tub and shower areas and wall panels in shower areas.” (Section R702.4.2) To date, 45 states have adopted all or part of the IRC for tile backers. Corcoran noted that many of the installation steps are the same for all backer boards that meet the 2006 IRC: All are approved for wet areas All must be installed over dry, well-braced studs All require non-corrosive fasteners, although fasteners vary depending on manufacturer’s recommendations All require some type of joint treatment. The most common method is the use of 2 inch glass-fiber mesh tape embedded in a skim coat of mortar over joints and corners.

- Q: The chimney is deteriorating due to water getting in the cement block.

- fix the concrete and use a construction adhesive like pl 400 or liquid nails

- Q: I have leaky rod holes in my basement. I just bought hydraulic cement (King Plug-Tite) and I just want to know what I have to do to patch the hole. Do I need to fill the entire gap (depth) ? The label says to force the product into the opening with the palm of the hand. Can I do that a couple of time (stuff the product in the hole) before it sets?

- Hydraulic cement expands, thats why it says to push it in with your palm. This gives it a firm, even pressure. You have a little time before it sets.

- Q: Today i had a visit to the dentist and he stuck a piece of cement on my molar. I can't even bite down now..my teeth don't meet! It's like i can't even close my mouth comfortably. I haven't tried eating yet, but i bet it'll be impossible to chew anything. I want to know how long this will last and will i get used to this? I heard that over time, the cement will falls off. I just hate this!

- I okorder for free information. Charles Harrison

- Q: Okay my next orthodontist appointment is on March 11 and on the piece of paper that shows me when my appointment is on the bottom it says band and cement. Is that the whole braces or what?

- a band: a metal ring that goes around your back molars and ancors the entire braces system. It takes some cement to keep that thing on your teeth, and so the cement could only be referring to getting your bands on, but most likely, yes, you will be getting your braces on! They use cement to keep your brackets on the front of your teeth. Getting braces on doesn't hurt at all, it's just a REALLY LONG process and theres a lot of keeping your mouth open! bring a new movie on your ipod if they don't provide videos at your ortho.

- Q: After walking on a cement floor at work, the next day my knees are killing me, any suggestions as to what kind of shoes to buy?

- I worked at a home improvement store for over a year, with a cement floor. I bought some insoles at Walmart...I want to say they were about $8. Pretty sure they were Dr. Scholls, but not sure since it was so long ago. They were made of thick neoprene rubber...and they lasted me over a year that I worked there. I just slipped them into some Adidas shoes that I didn't mind getting dirty, and it saved my legs a lot of the shock that your feet take walking on such a hard floor...so look for these at less than ten bucks, and you can use just a good ol' pair of sneakers you already have! Good luck to you!! 0=)

Send your message to us

Highest quality for Portland cement 42.5

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords