Manufacture Of Pediment Ornament Mould

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 5000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

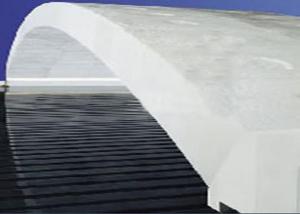

Introduction Of Pediment Ornament Mould:

GRC material has excellent constructive performance in history of building construction. With high strength and good nature, it is fireproof, mildew and worm resistant, moisture proof, and sound and heat insulated. It can be processed by nailing, adhering and patching, thus it is easy and convenient in construction.

Description Of Pediment Ornament Mould:

High strengh

Corrosion resistance, anti-frost and waterproof

Natural and hand crafted

Durable

Component Of Pediment Ornament Mould:

Glass Fibre Reinforced Cement(Cement, Alkali Resistant Glass Fibre / protofilament), short for GRC/GFRC

Advantage Of Pediment Ornament Mould:

Strong, Tensile-strength: 1800 Mpa, twice to triple as much as that of steel fibre.

S. G.: 2.7

Durability: Over 10 years

High heat-resistant: Its softening point is about 860

Anti-frost, waterproof&fireproof, mildew&worm and corrosion resistance

UV-protection&environment friendly

Maintenance free

Customer designs are available. Our products are very popular with domestic and abroad market. We have built a steady and long-term cooperation relationships with Chinese top 20 real estate companies and our products are exported to the Middle East, Western Europe, North America, South Africa and other countries and regions.

- Q: Current rates for cement,steels,tiles,workers fee?

- sophisticated thing lookup at yahoo and bing that can help

- Q: When building a green house, it is important for it to be cool in the summer and warm in the winter. Of course, to do this, energy is required, but to make if energy efficient, a dirt floor might be better, as this would allow for heat production from the earth. However, dirt is not a good insulator, but cement is, so concerves the heat better. What do each do to cold?

- if you got money you could use geothermal heating where they bury the pipes deep under ground and use natural heat from the earth. definitely cement floors with a 1 foot footing around the perimeter to keep rodents from digging and sheltering under the slab. then install a draining system and pitch the concrete for easy clean up. the concrete also provides a more stable foundation for the walls if anchored correctly. just depends on how much you want to spend.

- Q: well my name is carved into the cement driveway next to my house. if my parents see that i'll be in BIG trouble. so does anyone know how to like remove writing out of the cement driveway? please anyone help. 10 points for the most helpful answer.

- Pouring cement into the grooves won't help. You may have to dig it up and put in new cement. Even caulk, which will fill the grooves, won't match the color, and it will still be visible. But I'd try that first. Get some cement caulk from a hardware store. At least you can tell your parents you tried. maybe put a lot of dirt over it, they may not notice if for a while. .

- Q: builders have messed it up..i live somewhere hot..2 attempts of cement laying and then a green paint over it which i've had to scrape off...the paint still keeps coming off tho when mopped...can you suggest please some sort of sealant i can get bought in england and sent over to me?just to make it look better and 'seal' in the colour..cheers :)

- Pressure wash, let dry. Buy Dutch Boy floor and porch enamel, Flat so it won't be slippery. It can be mixed to the color you want. Since the paint keeps rubbing off, I thought you still had this problem. Dutch Boy Enamel will take care of it, since you'll have to cover it with a sealer anyways. I'm really not a strong believer in a sealer at this point, for 1 it's a floor that has heavy traffic. Sealers are meant for wood floors, to protect from scratches, and looks of the hardwood.

- Q: What are the differences between 43 grade and 53 grade cement?

- The strngth of cement such as 53 or 43 grade does not hold any consideration during calculation of Mix Design. It has no parameter at all. More over in India Hybrid no cement has been designated in grade apart from 33 grade. Over and above use of OPC cement all over the world is decreasing considerably. Hence by producing higher grade of cement the Cement Companies simply befooled us.

- Q: over the years the cement floor has settled and broken at the opening of the overhead door. can someone tell me the right way to do the repairs, or send me to a site that i could get some directions. one of my main concerns is the side jams of the doorway. can you fill the level of cement above the boards? Thanks for your help.

- Best to have the concrete removed and replaces, but this we be costly. answerman3 answer is the cheaper way to go, but you should saw or grind the cracks before filling.

- Q: Make the yard with cement is cheaper or brick is cheaper? thanks!?

- Get contractor estimates for both. Cement is a lot of manual labor, but the materials will be cheaper. Brick is the other way around. Good luck! We are in the middle of our own extensive backyard remodeling, and found that the cost of materials will vary greatly depending on your locale and how far the materials have to be transported. I'd shop around a couple local garden supply stores, and then get estimates for the labor from contractors. If you don't know the price of your materials, contractors are likely to inflate the prices if they procure them for you.

- Q: Okay, I have some 4quot;PVC to 2quot;PVC reducer, a 4quot; PVC tank/endcap, and a ball valve. It is going to be under a lot of pressure (70-100PSI), this is my first time bonding PVC so what should i do in steps? I heard PVC Primer then Cement it together. Anything else?

- If temperature is a factor you may need to know this: Type I PVC 2” sch A max psi @75° = 115, @150° = 65 2” sch 40 max psi @75° = 195, @150° = 110 2” sch 80 max psi @75° = 280, @150° = 150 2” sch 120 max psi @75° = 320, @150° = 170 Type I PVC 4” sch A max psi @75° = 115, @150° = 65 4” sch 40 max psi @75° = 155, @150° = 85 4” sch 80 max psi @75° = 225, @150° = 120 4” sch 120 max psi @75° = 295, @150° = 155 Cement work well in most applications but hot welding may be required. If your using cement use a primer on both the fitting and the pipe and apply cement to the pipe only, insert and twist

- Q: Im trying to level my floor with self levelling cement. I know its supposed to be runny but i may have put too much water on it. Unfortunately i already dumped it on the floor. Will it eventually dry up.

- Yes it will dry up just trowel it as smooth as you can and let it set up over night

- Q: my husband just started working at this contruction-like plase by demolishing houses, he came home one day and later that night his nose started bleeding uncontrolably, i dont know if it was because its hot or because hes breathing in dirty air or cement or dust or i really dont know. i just want to know if hes going to be okay, because hes the kinda guy that says quot;no im allrightquot; but hes dying. he doeant have any breathing problems or asma.

- This Site Might Help You. RE: is cement harmless to breath in? my husband just started working at this contruction-like plase by demolishing houses, he came home one day and later that night his nose started bleeding uncontrolably, i dont know if it was because its hot or because hes breathing in dirty air or cement or dust or i really dont know. i just want...

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2006 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Manufacture Of Pediment Ornament Mould

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 5000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords