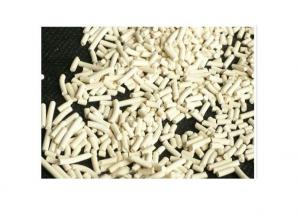

High Quality PP Fiber Reinforced Concrete

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000 Kgs kg

- Supply Capability:

- 100000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality PP Fiber Reinforced Concrete:

PP fiber,also called Polypropylene PP Fiber, Polymer Fiber, it is manufactured by mixing, spinning, stretching and cutting the combination of modified base and polypropylene paring, used as the project fiber for concrete and mortar. It can decrease cracks in concrete's early stage.

Property of High Quality PP Fiber Reinforced Concrete:

Polypropylene monofilament fiber technical | ||

Item | Product Name | PP fiber |

1 | Material | 100% polypropylene |

2 | Cut length | From 3mm to 120mm |

3 | density | 0.91g/cm³ |

4 | Diameter | 20 micron to 40micron |

5 | Strength | 400-600Mpa |

6 | elongation break | 30%-40% |

7 | melting point | 170°C |

8 | ignition point | 590°C |

9 | Oil point | lower than 1% |

10 | Water-hygroscopicity | No |

Advantages of High Quality PP Fiber Reinforced Concrete:

Good dispersancy, better grip

Random dispersal, subordination reinforced

Physically-added tendon, anti-crack and high reinforcement

Diamagnestism and antirust, corrosion protection and alkali resistant

Innocuous and odorless, safe

Simple operation, more economic and dependable

Function of High Quality PP Fiber Reinforced Concrete:

Anti-crack

Increasing seepage-proof performance

Anti-concussion and anti-wear performance

Increasing shock proof

Cold-resistant property

Enhance the property of toughness and ductility

Fire resistance and anti-detonation quality

Preventing or reducing the major reinforcing steel bar from being eroded

Reducing rebound of jetting concrete

Applications of High Quality PP Fiber Reinforced Concrete:

Industry and Civil Architecture

Main body of road, bridge

Water conservancy project

Package & Delivery of High Quality PP Fiber Reinforced Concrete:

A: Packing in plastic bags, plastics bags to be put into waterproof bags, and then waterproof bags to be put into container, totally 8 tons in 1x20'FCL

B: Packing in fusible paper bags, paper bags to be put into cartons, and then cartons to be put into pallet, pallets to be put into container, totally 6 tons in 1x20'FCL.

- Q: and it was lumpy can i still use it or will the lumps interfer with the leveling process, ( and how liquidy should i make it) i experimented with a little amount and it just didn't look right so i threw it out.. it's the firt time i'm using a self leveling product

- Never NEVER try to work with lumpy cement. Toss it and start over. Mix well make sure you enough but not too mcuh water. Cement of any type needs to be smooth and easily spread.

- Q: Where does slag cement is best utilized? Which stage of construction it is to be used?

- hey guys plz can anyone tell me Why Blast furnace slag cement is prohibited to use in thin Reinforced concrete cement structures?

- Q: I have built a dry stacked concrete block wall as a fence around our home. I am wondering if I should use premixed cement or mix it myself. What is the best mix recipe for a Surface Bonding Cement mix?

- Your location will influence the decision to buy premix or use a DIY mix. If you can easily buy the premix locally, that will probably be your best choice. The premix will usually have a better feel and probably performance because the manufactures have the ability to engineer the product on a much larger scale than can be done onsite. Since the original guide was published there have been many improvements to the available additives. The Calcium Chloride and Calcium Stearate may no longer be the best choice for surface bonding mix.

- Q: My basement shower is basically just a cement slab with a drain and fiberglass walls. What's a rough ballpark cost estimate to tear out the cement shower and replace it with a modern glass stall and/or a tile shower?

- By cement slab you refer to the concrete basement floor with a drain in it? Nothing to tear out. A contractor will install a shower pan. Either custom made or a prefab pan and tie into the existing drain. If you want to relocate the shower then he will jack hammer up the slab and run the drain. Save money by having the shower in the same place. For just the shower pan and walls framed, covered with backer board, tile tie into existing hot and cold water supply figure about $4000. If you want to use custom materials like granite and limestone tiles add $1000. Also plan to install an exhaust fan for the steam. If you can be happy with a prefab fiberglass surround it will be half the cost.

- Q: quot;What date was cement made?

- 1.Cement is made by heating powdered limestone and clay. 2.It is used in mortar and concrete - mortar is used to join bricks together and is made by mixing cement with sand and water - concrete is made by mixing cement with sand, water and aggregate (crushed rock) 3.it sets and hardens quickly so building is faster. 4. Portland cement mortar was invented in 1794 and patented in 1824. It gained in popularity over lime mortar by the latter part of the 19th century and by 1930 has all but replaced lime mortar for new construction. Lime mortar was first used in Mesopotamia and was made by heating up limestone to drive out the water, then grinding it to a powder, which had sand added to it for greater strength. To use it, water was mixed to it to form a paste which slowly hardens. It was used in the Pyramids.

- Q: What is water/cement ratio?

- some of one and a bit of the other

- Q: I've tried to make the cement (on Whuddle World) and it always says that i'm unable to make it.WHY!?!

- to mix a cement, u need this : 1 bag full of cement a bottle of water ( u need oil to pump water. for oil, just go to gadget n gizmos, enter the 1st lab, click oil can near pink tube) sand ( get it free at playground (NE ww) bucket ( talk to farmer noggin, then search it by clicking around a pile of hay in farmer barn.. keep clicking till you find it) a trowel ( go to hickory hardware n woodworks, click a garden spade which is hanging on the wall. just keep clicking around it till u'll receive msg that wud kraft let u borrowed his trowel) now only u can mix it by clicking ur bucket in ur omnimbus. click use bucket and u now can start mixing it by dragging the items in correct order. 1. bucket, 2. cement. 3. water. 4. sand now u just mix the cement and make sure u carry the it. go to charlie fountain and click the statue. n dont forget to talk to chelsea to receive your awards.. hope this help all whuddles.. cheer up!!!

- Q: I am looking forward to building a block fence. I ran into a YouTube video on the Quikwall surface bonding cement and was curious on your thoughts about that product. Have you tried it? On what and what do you think about it? Thanks!

- Quikwall Surface Bonding Cement

- Q: I am putting tile on the wall in my bathroom (not in the shower), do i have to put cement board behind it?or can i just leave the drywall that is already there?

- This Site Might Help You. RE: Do i have to put cement board behind tile on the wall? I am putting tile on the wall in my bathroom (not in the shower), do i have to put cement board behind it? or can i just leave the drywall that is already there?

- Q: I recently had my braces removed and while looking in the mirror at my teeth, I noticed black discoloration on several teeth. Is this a common color of the adhesive they use or did my teeth somehow get massive cavities?

- Orthodontic cement is clear hen they out it on and sort of whitish when it dries. So I have no idea what's on your teeth.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port,China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; Russian; Spanish |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality PP Fiber Reinforced Concrete

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000 Kgs kg

- Supply Capability:

- 100000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords