High Quality PP Fiber Mesh for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber Introduction

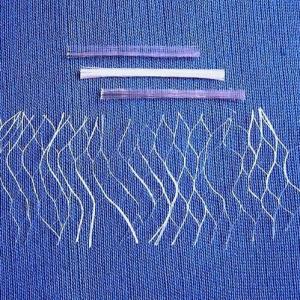

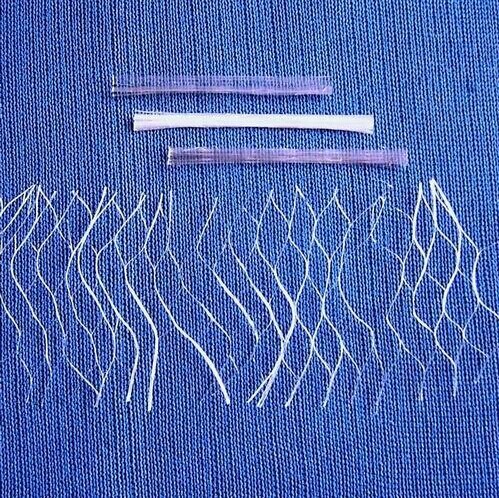

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

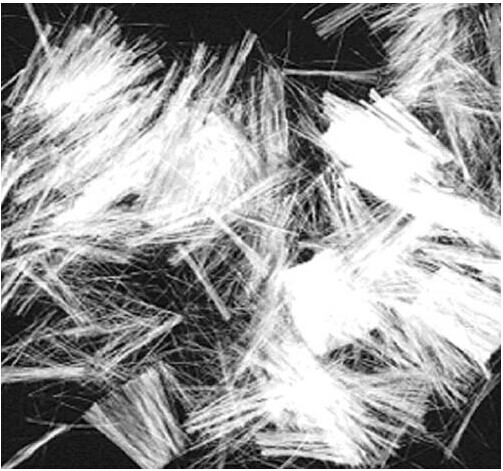

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Introduction of PP Fiber Mesh for Concrete Use

With polypropylene as its raw material..this fiber is produced by special technology. The products appear net-like structure with many fiber monofilaments connected.

When the fiber is put into the concrete ,the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing to friction and rubbing. And the fiber monofilament or net –like structure will fully stretch, thus the concrete is reinforced by great number of polypropylene fibers.

Technical Data of PP Fiber Mesh for Concrete Use

Density(g/cm3) | 0.91 | Elastic Modulas(MPs) | >3000 |

Length(mm) | 12±1,19±1 | Equivalent Diameter(um) | 100 |

Shape | Beam-like Net | Crack Elongation(%) | 15%-50% |

Acid &Alkali Resistance | Strong | Water-Absorbency | No |

Tensile Strength(MPa) | >350 | Melting Point(C) | 160-170 |

Functions of PP Fiber Mesh for Concrete Use

·increase seepage resistance

·Strengthen spurt & fatigue

·Prolong endurance

·Improve tensile,bending & folding strength

·Improve steel protection

·Improve plastic deformity

·Increase cracking resistance

·Strong acid & alkali resistance and good

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

Application of PP Fiber Mesh for Concrete Use

- Q: Can earthwork products be used in road embankment construction?

- Yes, earthwork products can be used in road embankment construction. Earthwork products, such as soil, gravel, and other materials, are commonly used to build up road embankments. These materials are compacted and layered to create a stable foundation and to ensure proper drainage.

- Q: What are the different design options available in earthwork products?

- The different design options available in earthwork products include various materials such as rocks, gravel, sand, and soil, as well as different shapes and sizes of these materials. Additionally, there are different techniques for arranging and layering these materials to achieve specific design goals, such as slope stabilization, erosion control, or landscaping features.

- Q: Can geosynthetics be used for bridge abutment reinforcement?

- Yes, geosynthetics can be used for bridge abutment reinforcement. Geosynthetics, such as geotextiles and geogrids, can provide additional strength and stability to bridge abutments by improving soil reinforcement, reducing soil erosion, and preventing settlement. They can be used to reinforce the soil backfill behind the abutment walls, increase bearing capacity, and enhance overall structural performance.

- Q: What are the advantages of using geogrids in earthwork projects?

- Geogrids offer several advantages in earthwork projects. Firstly, they enhance soil stability by providing reinforcement and increasing the load-bearing capacity of the soil. This helps in constructing structures on weak or poor-quality soils. Secondly, geogrids distribute the applied load more evenly, reducing the potential for differential settlement and minimizing the risk of structural failure. Additionally, they improve the overall performance and longevity of the project by reducing the need for excessive excavation or the use of costly reinforcement materials. Lastly, geogrids are easy to install, cost-effective, and environmentally friendly, making them a preferred choice for engineers and contractors in various earthwork applications.

- Q: What are the types and properties of commonly used civil engineering materials?

- Classification by material source According to the material source, can be divided into natural materials and man-made materials. The man-made materials can be metallurgical, kiln (cement, glass, ceramics, etc.), petrochemical and other materials manufacturing sector to classify.

- Q: What are the limitations of using geosynthetics in certain soil conditions?

- Geosynthetics may have limitations when used in certain soil conditions due to factors such as poor soil compatibility, high groundwater levels, or extreme temperature variations. Inadequate soil compaction or the presence of expansive soils can compromise the performance of geosynthetics, leading to potential failures or reduced effectiveness. Additionally, in areas with high water tables, geosynthetics may experience buoyancy issues, affecting their stability. Extreme temperature fluctuations can also impact the durability and integrity of geosynthetics, potentially leading to degradation or reduced performance. Therefore, careful consideration of soil conditions is necessary to ensure the successful use of geosynthetics.

- Q: Can earthwork products be used in mining and quarrying operations?

- Yes, earthwork products such as soil, rocks, and aggregates can be used in mining and quarrying operations. These products are commonly utilized for various purposes in these industries, such as backfilling excavated areas, constructing haul roads, reinforcing slopes, and creating foundations for structures.

- Q: Can geosynthetics be used to stabilize slopes?

- Yes, geosynthetics can be used to stabilize slopes. Geosynthetics such as geotextiles, geogrids, and geocells are commonly used in slope stabilization projects. These materials can provide reinforcement, erosion control, and drainage solutions, thereby enhancing the stability and long-term performance of slopes.

- Q: Can earthwork products be used in erosion control on construction sites?

- Yes, earthwork products can be used in erosion control on construction sites. These products, such as geotextiles, erosion control blankets, and sediment control devices, are specifically designed to prevent erosion and control sediment runoff during construction activities. They help stabilize soil, control water flow, and protect exposed surfaces, ultimately reducing the potential for environmental damage and maintaining site safety.

- Q: Are earthwork products resistant to extreme temperature variations?

- Yes, earthwork products are generally resistant to extreme temperature variations. The inherent properties of earth materials, such as soil and rock, allow them to withstand temperature changes without significant damage. However, it is important to note that certain earthwork products may require additional measures, such as proper compaction or stabilization techniques, to ensure better resistance to extreme temperature variations.

Send your message to us

High Quality PP Fiber Mesh for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches