Geocomposite Drainage Geonet Liner HDPE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

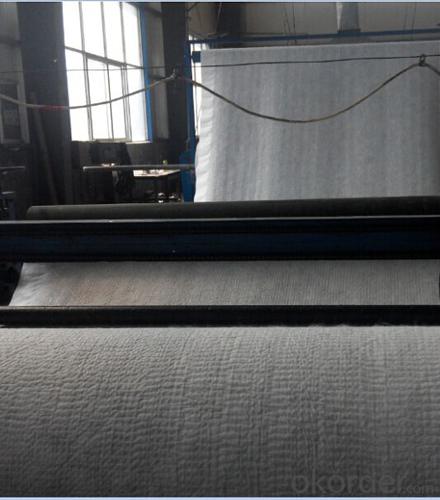

Three-dimension Composite Drainage Network Introduction

Geonet can be used in the soft soil stabilization, base reinforcement, embankments over soft soils, seacoast slope protection and reservoir bottom reinforcement, etc

It prevents the slope rock from falling down ,which avoids the hurt to the human beings and the vehicle on the road; It prevents the road dregs packed by geonet from being washed away ,avoids the roadbed distortion and improves the stability of the roadbed; laying the geonet reinforces the road surface ,avoids development of the reflection crack. As reinforcing material of filling soil in retaining walls, it disperses the earth body stress and restricts the side-displacement. The stone cage, made of geonet, can prevent erosion ,collapsing and lost of water and soil when being used in dyke and rock slope protetion

Specification

Geonet thickness: 5-8mm; Width: 2-4m; Length as requested

Geotextile can be needle punched polyester geotextile, continuous filament PET nonwoven geotextile or Polypropylene nonwoven geotextile, and the unit weight normally 200g/m2.

Features

1. Excellent drainage function, able to bear long time high pressure load

2. High tensile and shear strength

3. Able to protect its long time and stable hydraulic conductivity

4. Able to bear more than 2000kpa compression load, its anti-pressure capacity much higher than common drainage network

5. Corrosion resistant, acid and alkali resistant.

Application

Landfill drainage; Roadbed and road drainage; railway drainage; tunnel drainage; underground structure drainage; the retaining back wall drainage; garden and sports ground drainage.

Geonet is made of HDPE and anti-ultraviolet additives

1. Anti-aging, corrosion resistance

2. Highway and railway subgrade: effectively distribute load, improve its bearing capacity and stability and prolong service life

3. As layer of highway slope so that geonet can prevent landslide and protect water and soil, and beautify the environment

4. In reservoir and rive dykes to effectively prevent landslide; in the coastal engineering because of its soft good toughness, corrosion strong characteristic to buffer wave swept and corrosion

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

- Q: How are geotextile tubes used in sediment dewatering?

- Geotextile tubes are used in sediment dewatering by creating large containment structures that allow water to drain out while retaining the sediment. The tubes are usually filled with sediment slurry and then left to settle. As the water drains through the permeable geotextile fabric, the sediment particles are trapped inside, resulting in dewatered sediment that can be easily disposed of or repurposed.

- Q: How do earthwork products help with sediment control?

- Earthwork products help with sediment control by providing physical barriers and erosion control measures to prevent soil erosion and sediment runoff. These products, such as sediment control blankets, silt fences, and sediment basins, help to trap and retain sediment on construction sites, preventing it from being washed away by rainfall or runoff. By keeping sediment in place, these products protect nearby water bodies from pollution and maintain the overall health of the ecosystem.

- Q: Are there any earthwork products specifically designed for oil and gas projects?

- Yes, there are earthwork products specifically designed for oil and gas projects. These products include geotextiles, geomembranes, geogrids, and erosion control materials. They are used to provide soil stabilization, prevent erosion, control sediment, and protect the environment during oil and gas exploration, drilling, and production activities.

- Q: Are earthwork products available in various colors and finishes?

- Yes, earthwork products are available in various colors and finishes.

- Q: How are geosynthetics used in drainage systems?

- Geosynthetics are used in drainage systems to improve their performance and efficiency. They are often used as filters to prevent soil particles from clogging the drainage pipes, allowing water to flow freely. Geosynthetics can also be used as separators to prevent the mixing of different soil layers, ensuring proper drainage. Additionally, they can be used as reinforcements to enhance the stability and durability of the drainage system, preventing soil erosion and maintaining its integrity.

- Q: What are the types and properties of commonly used civil engineering materials?

- According to the use of functional classification According to the civil engineering materials in the building parts or the use of performance, can be divided into building materials, wall materials, building functional materials three categories.

- Q: Are there any earthwork products specifically designed for road construction?

- Yes, there are several earthwork products specifically designed for road construction. These include materials such as aggregate, asphalt, concrete, gravel, and soil stabilizers. Additionally, there are specialized tools and equipment like graders, compactors, and excavators that are used extensively in road construction projects.

- Q: Questions about civil engineering materials

- First, with excellent adhesion, construction, anti-droop, so that the formation of waterproof between the continuum; second, with good flexibility, can withstand structural parts due to temperature, humidity, wind, earthquake And so on caused by the seam deformation; Third, with weather resistance, water resistance, long-term outdoor sunshine, rain, snow and summer heat and other conditions under the effect of maintaining long-term adhesion and tensile compression performance.

- Q: What is the purpose of using geotextile tubes in dredging projects?

- The purpose of using geotextile tubes in dredging projects is to efficiently contain and dewater the sediment that is being dredged from bodies of water. The tubes provide a cost-effective and environmentally friendly solution by allowing the water to drain out while retaining the sediment, preventing it from spreading and causing pollution.

- Q: Can earthwork products be used in geotechnical engineering applications?

- Yes, earthwork products can be used in geotechnical engineering applications. Earthwork products such as soil, gravel, and rocks are commonly used in various geotechnical engineering projects, including road construction, foundation design, slope stabilization, and retaining wall construction. These materials are often utilized to improve soil properties, provide stability, and enhance the overall performance of geotechnical structures.

Send your message to us

Geocomposite Drainage Geonet Liner HDPE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords