Polypropylene Fiber for Reinforcement with 12mm 18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber Introduction

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Technical Data of Polypropylene Fiber for Reinforcement with 12mm 18mm

Raw Material | Polypropylene | Crack Elongation | 20%±5% |

Type | Monofilament | Density | 0.91±0.01g/cm3 |

Fiber Diameter | 0.02-0.05±0.005mm | Melting point | 160-170 |

Tensile strength | ≥450mpa | Resistance to acid, alkali | Strong |

Size | 6, 12, 10, 15, 19, 20, 24, 48mm | Water absorbency | no |

Product Function of Polypropylene Fiber for Reinforcement with 12mm 18mm

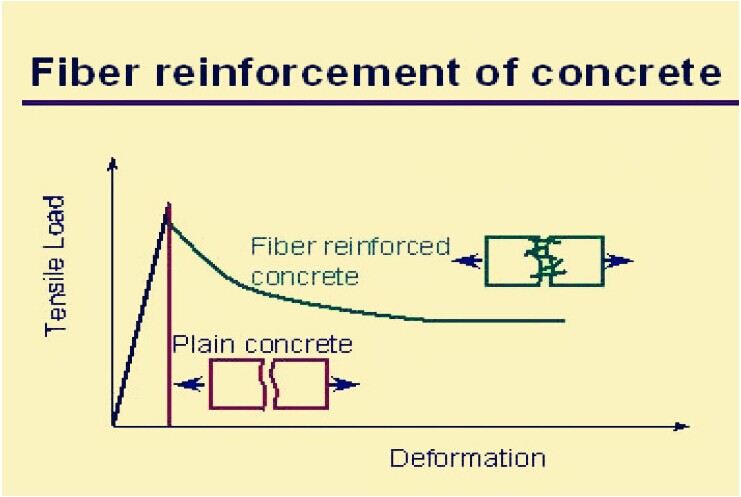

1) improve the crack resistance of mortar and concrete

2) improve the permeability resistance of mortar and concrete greatly

3) improve mortar, concrete resistance to impact, bending and seismic performance

4) improve wear resistance of mortar and concrete

5) improve the antifreeze performance of mortar and concrete

6) strong dispersion, workability

7) good chemical stability, acid and alkali resistant capability is strong, safe non-toxic, for reinforcement corrosion damage

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

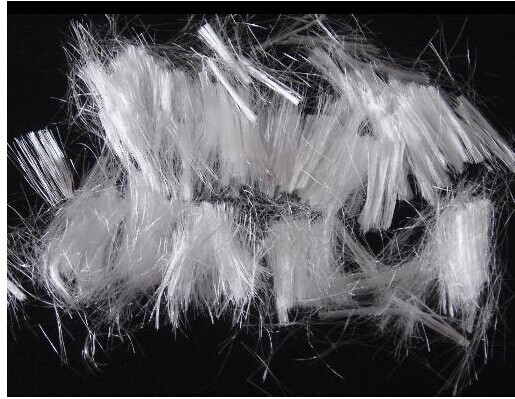

Product effect Photo of Polypropylene Fiber for Reinforcement with 12mm 18mm

4. Product Application of Polypropylene Fiber for Reinforcement with 12mm 18mm

1), building engineering, mortar, concrete structure of civil and industrial buildings, including site casting, beam-column, the basement floor and side panel, roof cast-in-place floor slab, pool structure, crack resistance, impact resistance, high wear resistance requirements of engineering.

2), municipal engineering, concrete road and square, bridge, tunnel, subway, port terminals, interchange bridge, bridge, airport runway, super long structure, etc.

3), water conservancy project: levees, DAMS, etc.

4), antiknock, refractory engineering: civil air defense, military engineering, oil platform, chimneys, refractory materials, etc.

5), shotcrete, tunnel, culvert lining, thin-walled structure, slope reinforcement, etc.

5. Product Show of Polypropylene Fiber for Reinforcement with 12mm 18mm

- Q: Can earthwork products be used in green infrastructure projects?

- Yes, earthwork products can be used in green infrastructure projects. These projects often involve the use of natural materials and techniques to manage stormwater, improve water quality, and enhance the overall sustainability of an area. Earthwork products, such as soil, compost, and mulch, can play a crucial role in constructing green infrastructure elements like rain gardens, bioswales, and permeable pavement systems. These products help to create healthy soil conditions, promote water infiltration, and support the growth of vegetation, which are essential components of green infrastructure projects.

- Q: In addition to cement, but also add gelling agent

- The development of cementitious materials has a long history, people use the earliest cementitious material - clay to wipe the simple building. Then there are cement and other building materials and cementitious materials have a great relationship.

- Q: Can earthwork products be used in mining tailings management?

- Yes, earthwork products can be used in mining tailings management. Earthwork products such as geosynthetics, geotextiles, and geomembranes can be utilized to construct and reinforce containment structures for mining tailings. These products can help prevent seepage and control the flow of water, reducing the risk of environmental contamination. Additionally, earthwork products can also be used for erosion control and slope stabilization in mining tailings management.

- Q: How are geotextile bags used in erosion control?

- Geotextile bags are commonly used in erosion control to stabilize slopes, prevent soil erosion, and protect coastal areas. These bags, filled with sand or soil, act as a barrier against water flow, reducing its velocity and preventing the scouring of soil particles. The geotextile fabric allows water to pass through while retaining the soil particles, effectively controlling erosion and promoting vegetation growth. Additionally, these bags can be used to construct retaining walls, revetments, and gabions, providing long-term erosion protection solutions.

- Q: What are the different types of erosion control blankets available?

- There are several types of erosion control blankets available, including straw blankets, coconut fiber blankets, and synthetic blankets.

- Q: Civil engineering materials, what kind of

- Classification by material source According to the material source, can be divided into natural materials and man-made materials. The man-made materials can be metallurgical, kiln (cement, glass, ceramics, etc.), petrochemical and other materials manufacturing sector to classify.

- Q: How do geosynthetic liners prevent seepage in stormwater detention ponds?

- Geosynthetic liners prevent seepage in stormwater detention ponds by acting as a barrier between the pond and the underlying soil. These liners are made of impermeable materials, such as geomembranes or geotextiles, which restrict the flow of water through them. By installing these liners in the pond's base and sides, they effectively prevent water from seeping into the ground, reducing the risk of contamination and ensuring proper stormwater management.

- Q: Can geotextiles be used for filtration purposes in earthwork projects?

- Yes, geotextiles can be used for filtration purposes in earthwork projects. Geotextiles are permeable fabrics that can effectively filter different types of particles and materials from passing through while allowing water to flow through them. This makes them suitable for applications such as erosion control, drainage systems, and separation of different soil layers in earthwork projects.

- Q: What are the key considerations when using geotextile mats for erosion control on golf courses?

- When using geotextile mats for erosion control on golf courses, there are several key considerations to keep in mind. Firstly, it is important to select the right type of geotextile mat based on the specific erosion control needs of the golf course. The mat should be able to withstand the anticipated flow of water, maintain its integrity under various weather conditions, and effectively prevent erosion. Secondly, proper installation is crucial. The mats should be placed securely and anchored appropriately to ensure they stay in place during heavy rainfall or irrigation. This may involve using stakes, pins, or other fastening methods to secure the mats to the ground. Additionally, maintenance and monitoring are essential for long-term effectiveness. Regular inspections should be conducted to check for any damage or signs of erosion. If any issues are identified, they should be addressed promptly to prevent further erosion. Lastly, it is important to consider the aesthetics of the geotextile mats. They should blend well with the surrounding landscape and not detract from the overall appearance of the golf course. Overall, by carefully considering the type of geotextile mat, proper installation, regular maintenance, and aesthetic integration, golf courses can effectively utilize geotextile mats for erosion control and maintain a visually appealing course.

- Q: Civil engineering materials what is the toughness of the material

- Material in the middle of the process of elastic deformation and fracture, the ability to absorb bending energy, known as the toughness of the material.

Send your message to us

Polypropylene Fiber for Reinforcement with 12mm 18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords