Civil Works Material HDPE Geosynthetic Clay Liner

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Civil Works Material HDPE Geosynthetic Clay Liner(GCL)

1,Introduction

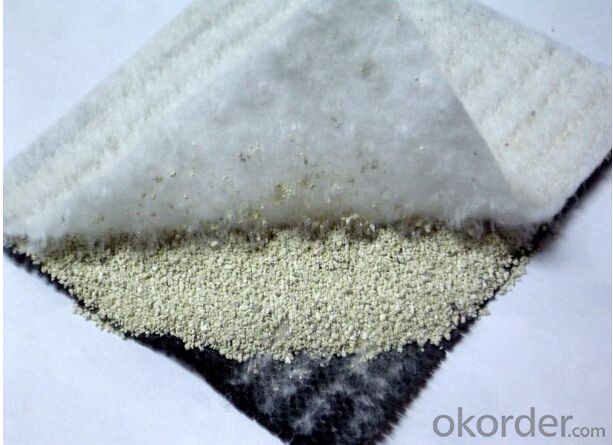

Our GCL is composed of 3 layers, the upper layer is nonwoven geotextile, while the lower layer is woven geotextile, natural sodium bentonite fills the gap between geotextile layers. The application with natural sodium bentonite can enlong the using life of construction. Our GCL creates a new green and environmental building material.

We have two kinds of GCL. One is GCL without HDPE layer, the other is HDPE GCL. For GCL, it is widely used in landfill, lagoon, river bottom, basement and so on. For HDPE GCL, it is used in subway, basement, tunnel, underground and projects, salt water area in harsh environment.

2,Features

1. Environment friendly

Our GCL is made of natural sodium bentonite, which contributes to good water proof quality, while causes no pollution to the environment. Its porosity guarantees the breath of biology.

2. Long-lasting waterproof performance

Natural sodium bentonite was formed billions of years ago. Its waterproof performance can last longer than building itself.

3. Easy application

Application of GCL is not constrained by weather. Connection and restore is easy to be finished.

3,Application

· Landfills | · Mud Pits |

· Lagoons | · Canals |

· Bund Lining | · Tank Lining |

· Fish Farm Lining | · Roof Lining |

· Waste Water Pits | · Ponds and Reservoirs |

· Dams | · Floating Covers |

· Vertical Cutoff Walls | · Hydraulic Structure |

· Basement Lining | · Drip Irrigation Ponds |

4,Specification of Geosynthetic Clay Liner(GCL) for anti-seepage

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

Can you provide free samples?

Yes, our samples are always free, but express fees ususlly on buyer's account.

- Q: What are the different material compositions of earthwork products?

- Earthwork products can be made from a variety of materials, including natural materials such as soil, gravel, and rocks, as well as synthetic materials such as geosynthetics and geotextiles. These different material compositions are chosen based on the specific requirements of the project, including factors like strength, drainage, and environmental considerations.

- Q: How durable are earthwork products?

- Earthwork products, such as retaining walls and erosion control measures, are generally designed to be highly durable. These products are made using materials like concrete, stone, or steel, which have proven to withstand the test of time and natural elements. Properly constructed and maintained, earthwork products can last for several decades, providing long-term stability and protection to the land and surrounding areas.

- Q: How do earthwork products help with soil erosion control?

- Earthwork products help with soil erosion control by providing physical barriers that prevent soil from being washed away by water or blown away by wind. These products, such as geotextiles or retaining walls, stabilize the soil and protect it from the erosive forces of nature. They also help in redirecting or controlling the flow of water, which further reduces erosion.

- Q: Can earthwork products be used in landscaping edging?

- Yes, earthwork products can be used in landscaping edging. These products, such as stones, bricks, or timber, can be used to create borders or edges for flower beds, walkways, or other landscaping features. They not only provide a neat and defined look to the landscape but also help in preventing soil erosion and maintaining the shape and structure of the landscaped area.

- Q: What are the advantages of using geotextile tubes for breakwater construction?

- Geotextile tubes offer several advantages for breakwater construction. Firstly, these tubes are cost-effective compared to traditional methods as they require minimal materials and labor. Secondly, they are highly flexible and can be easily shaped and positioned to meet specific project requirements. Thirdly, geotextile tubes are resistant to corrosion and degradation, making them durable and long-lasting. Additionally, they provide excellent erosion control and stability, protecting shorelines from wave action and storm surges. Finally, geotextile tubes are environmentally friendly, as they can be filled with locally sourced materials, reducing the need for transportation and minimizing carbon emissions. Overall, these advantages make geotextile tubes a superior choice for breakwater construction.

- Q: How do geogrids aid in stabilization of steep slopes in earthwork applications?

- Geogrids aid in the stabilization of steep slopes in earthwork applications by providing reinforcement and support to the soil. These geosynthetic materials are placed within the soil layers to create a strong and stable structure that can withstand the forces of gravity and erosion. The geogrids distribute the load more evenly and increase the tensile strength of the soil, preventing it from sliding or collapsing. This helps to maintain the integrity of the slope, minimize erosion, and enhance overall stability.

- Q: Can earthwork products be used as decorative elements in construction projects?

- Yes, earthwork products can be used as decorative elements in construction projects. They can be incorporated in various ways such as creating textured finishes, building retaining walls, constructing pathways, or even sculpting artistic features. Earthwork products like natural stones, rocks, gravel, or clay can add aesthetic appeal and enhance the overall design of a construction project.

- Q: How do earthwork products contribute to flood control?

- Earthwork products, such as embankments and levees, play a crucial role in flood control. These structures are designed to redirect and manage the flow of water, effectively reducing the risk of flooding. By creating barriers and channels, earthwork products help contain and control water levels during heavy rainfall or flooding events. Additionally, they serve as protective measures for low-lying areas, preventing floodwater from reaching vulnerable communities and infrastructure. Overall, earthwork products are essential in mitigating the impact of floods and safeguarding lives and property.

- Q: What are the advantages of using geosynthetic materials in road subgrade stabilization?

- There are several advantages of using geosynthetic materials in road subgrade stabilization. Firstly, these materials enhance the strength and stability of the subgrade, improving the overall performance and lifespan of the road. Secondly, they provide effective drainage, preventing the accumulation of water and reducing the risk of water-related damages such as erosion or frost heave. Additionally, geosynthetic materials offer flexibility and resistance to deformation, allowing the road to withstand heavy traffic loads and reducing the need for frequent maintenance. Lastly, they are cost-effective as they require less excavation and construction materials, resulting in reduced construction time and expenses.

- Q: Can earthwork products be used for soundproofing purposes?

- Yes, earthwork products such as soil, rocks, or clay can be used for soundproofing purposes. These materials have natural sound-absorbing properties that can help reduce noise transmission. Additionally, incorporating earthwork products into construction projects, such as building earthen berms or mounds, can create barriers that block or deflect sound waves, further enhancing soundproofing capabilities.

Send your message to us

Civil Works Material HDPE Geosynthetic Clay Liner

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords