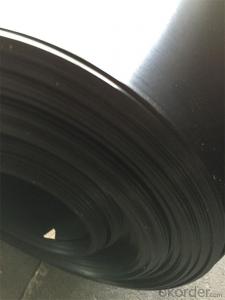

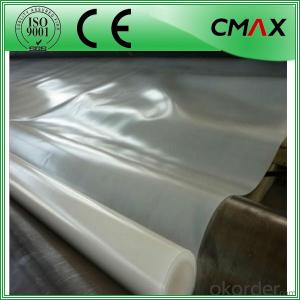

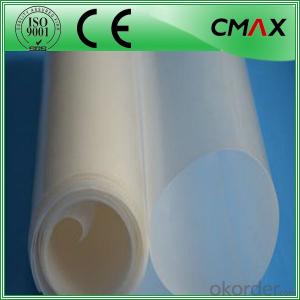

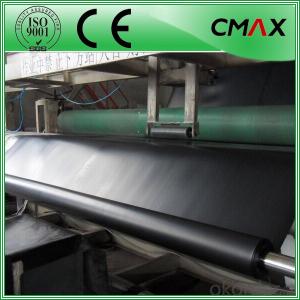

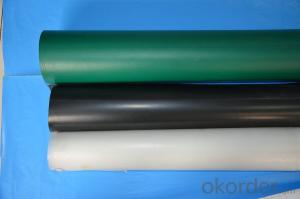

Geomembrane Pond Liner

Geomembrane Pond Liner Related Searches

Geomembrane For Ponds 30 Mil Pvc Geomembrane Pvc Geomembrane Institute Properties Of Geomembrane Plastic Geomembrane Geomembrane Material Geomembrane Fabric Harga Geomembrane Per Roll Geomembrane Roll Composite GeomembraneHot Searches

China Pvc Geomembrane China Geomembrane Roll Sheet Scaffolding Manufacturer In Mumbai Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Liner Price Geomembrane Price Black Plastic Plant Pots Wholesale Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Spring Manufacturer Singapore Bistable Spring Manufacturer Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Geomembrane For SaleGeomembrane Pond Liner Supplier & Manufacturer from China

Okorder.com is a professional Geomembrane Pond Liner supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrane Pond Liner firm in China.Hot Products

FAQ

- Geomembranes perform well in high-pressure applications. They are designed to withstand significant pressure and remain intact without any leakage or failure. The material used in geomembranes is highly durable and has excellent tensile strength, making it able to withstand the force exerted by high-pressure conditions. Additionally, geomembranes are often reinforced with additives or layers to enhance their resistance to pressure. Overall, geomembranes are reliable and effective in high-pressure applications, providing a secure barrier against liquids or gases.

- Yes, geomembranes can be used in floating covers for liquid storage. Geomembranes are impermeable membranes made of synthetic materials that can effectively contain and prevent the leakage of liquids. When used in floating covers, they can create a barrier between the liquid and the environment, effectively reducing evaporation and protecting the stored liquid from external contamination.

- nan

- Functions of fuser film: toner image transferred to the paper must heated so as to soften the resin in toner and make it firmly fix on the paper, fuser film plays the role of fixing roller as above. Why do people use fuser film to replace fixing roller? Printers are generally power on all day, especially multi-function printers are in service for 24 hours; but the fixing roller has a large thermal inertia and power consumption, internal heat is not easy to give off. In order to reduce the preheat standby time and achieve zero start, fixing roller is replaced razor-thin film. The features of fuser film: Fuser film is multilayer and generally divided into three layers: molding layer, base coat layer and surface coat layer; fuser film surface is easy to stick powder, and is electrical conductivity and thermal conductivity. How to choose a good fuser film? 1. good fuser film has a smooth inner wall, the size of inside diameter is identical to that of ceramic wafers, and it can rotate during the operation of machine. 2. uniform thickness, smooth surface coating, no miscellaneous points and unevenly coated places. 3. It is not easy to be broken for its good toughness, the same crease will not be broken even is has been folded for more than 50 times. It will not be teared up, and tearing can test its toughness to ensure that the film is not easy to be damaged in the machine. 4. ends face of both ends of film are smooth and burr-free. Yibang fuser film uses raw materials imported from Japan, and produced with excellent formula after fine machining. It has a good performance when printing various papers(copy paper, sulfuric paper, alabaster paper), the effect and service life of which can reach 90% of original products. It can resist tear strength of 5kg and it will not be broken; internal and external walls are smooth. It can be rotated freely even if it is not coated with grease.

- nan

- Article 2.1.1 Materials of the template and holder shall be steel, wood or new materials. The steel should be consistent with the No. 3 steel standard in the "Ordinary carbon steel grades and general technical conditions" (GB700-79). The timber should be consistent with the selection criterion of bearing structures under Code for construction quality acceptance of timber (GBJ206-83) , the tree species can be selected according to regional conditions, and the material grade shall not be under Ⅲ grade. Article 2.1.2 The template and holder must be in accordance with the following provisions: First,ensure the shape, size and position of engineering structures and components in each part is correct. Second, have enough strength, rigidity and stability, to withstand the weight and lateral pressure of newly poured concrete, as well as load generated in the process of construction.Third, simple structure, convenient assembly and disassembly, convenient for reinforcing bar colligation and installation and concrete pouring and curing process. Fourth, tight template joints without spillage. Article 2.1.3 The design, fabrication and construction of composite steel template, large formwork, climbing form and so on shall be in conformity with the relevant professional standards. Article 2.1.4 The contact surface of template and concrete shall be coated with separant. Do not use separant which will hinder the construction of decoration project. Article 2.1.5 The templates and holders shall be properly maintained, and the steel formwork and steel supports shall be prevented from corrosion.

- Geomembranes prevent water contamination by acting as a barrier between the surrounding soil and water sources. They are impermeable liners that prevent the migration of pollutants, such as harmful chemicals or waste materials, into the water. This helps to maintain the quality and purity of water by preventing any potential contaminants from seeping into the groundwater or nearby water bodies.

- Geomembrane film to buy underground for many years, that is to maintain anti-leakage function, or degradation of the time range, thank you

- Geomembrane life is mainly by the membrane is lost seepage barrier depending on the role, according to national standards, working conditions in the water under the conditions of up to 40 to 50 years, working conditions in the sewage conditions for 30 to 40 years. The general life of more than 50 years, geomembrane construction Notes: 1, the construction staff must wear non-staple or rubber shoes, to prohibit any trampling on the geomembrane. 2, after the film should be timely protective layer construction, to prevent heat shrinkage caused by geomembrane deformation and ultraviolet radiation caused by geomembrane aging. 3, prohibit contact with polyolefins can cause changes in chemical properties, so as not to permanent deformation of geomembrane. 4, the machine must not directly crush the surface of the geomembrane, the requirements of the geomembrane meet, the geomembrane life of the secret will gradually increase. Rigorous construction, can be a composite geomembrane users save time, effort, provincial costs, to achieve the best use of geomembrane state and effect.

- nan

- Model Specification Indicators Project WCS-1 WCS-2 WCS-3 WCD-1 WCD-2 one cloth and one membrane composite geo-membrane, two cloth and one membrane composite geo-membrane qualified impermeability strength (Mpa) First grade 0.4Mpa hydraulic?pressure impermeable 0.7 Mpa hydraulic?pressure impermeable 0.7 Mpa hydraulic?pressure impermeable 0.4 Mpa hydraulic?pressure impermeable 0.7 Mpa hydraulic?pressure impermeable qualified appearance First grade cloth smooth, no holes, fabric and film adhesion close, no stratification qualified

- Geomembranes prevent soil erosion by providing a barrier between the soil and external factors such as water, wind, and chemicals. They act as a protective layer, preventing the soil particles from being washed away or blown off by strong winds. Additionally, the impermeable nature of geomembranes prevents water from seeping into the soil, which reduces the potential for erosion caused by water saturation.