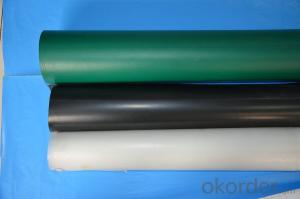

30 Mil Geomembrane Liner for Pond and Waterproof Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Specification of PE/ECB Geomembrane For Pond Liner

Item | Width(m) | Thickness(mm) |

LDPE geomembrane | 1-8 | 0.3-2.0 |

Physical Properties of PE/ECB Geomembrane For Pond Liner

Item | LDPE Geomembrane-1 | LDPE Geomembrane-2 |

Tensile Strength(Mpa) | ≥17 | ≥25 |

Fracture elongation(%) | ≥450 | ≥550 |

Tear strength(N/mm) | ≥80 | ≥110 |

Puncture resisitance(N) | 1.5mm(Thinkness)≥100 | 1.5mm(Thinkness)≥130 |

Size stability(%) | ±3.0 | ±3.0 |

Vapor permeation coefficient [g·cm/(cm2·S·Pa) | ≤1.0×10-16 | ≤1.0×10-16 |

Features of PE/ECB Geomembrane For Pond Liner

1. All physical factors such as anti-draw, anti-tear, and anti-stab meet the requirement of water works, chemicals, tunnels, and transportation project in most conditions.

2. Good aging, durable performance, and wide temperature range, it can be useful over thirty years on the condition of -60æ«60æ.

3. Anti-stab and fine friction factors.

4. Canker proof, acid and alkali proof, untoxic.

5. Lower cost per unit area, cost is 1/3«1/2 lower than that of PVC film, glass and cloth.

6. Convevient to install and dependable effect.

FQA:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: Can geomembranes be used in hydraulic structures?

- Yes, geomembranes can be used in hydraulic structures. They are commonly used as liners for reservoirs, dams, canals, and other water containment systems. Geomembranes are impermeable and resistant to various chemicals, making them effective in preventing water leakage and seepage in hydraulic structures.

- Q: How to get rid of protective film of the security door?

- There are many ways: 1: If the area is small, you can dip it in banana oil, and then wipe with a clean cloth. 2: Textile industry detergent (bottled one is called A1) can be used to remove it. I have tried the method with good result. 3: Dip it in the mixtue of sulfuric acid and water (or it will cause erosion), and rub with a clean ball after that. 4: Blow it with electric hair dryer, and then tear or remove with a wooden shovel. Solvent oil can be used to remove glue traces.

- Q: Can geomembranes be used in fishpond lining?

- Yes, geomembranes can be used in fishpond lining.

- Q: What materials does geomembrane belong to?

- Geomembrane belongs to impermeable material.

- Q: How to separate the non woven fabric from the waterproof board?

- Installation and construction of HDPE geomembrane shall be in accordance with the specific site condition and climatic conditions, properly pre-place 2%-5% extension volume; level surface mounting of base, remove the roots, stones and other sharp objects; trim round internal and external corners with its fillet radius equal to or more than 50cm; welding seam surface must be clean; welding seam should adopt displacement installation to avoid cross-wire welding, T-shape installation is available; using the side ditch anchoring landfill or bead seal installation; welding uses double track thermal melting, monorail hot melt, squeezing welding rod welding; seam take junction width is 10cm-15cm.

- Q: What is made of stretch film?

- Composite stretch film is currently the most widely used and largely consumed, occupying more than 40%of the overall consumption of plastic packaging stretch film. Since polyethylene containing no polar group has high crystallinity and low surface free energy, so surface treatment is required before printing and composite. Low density polyethylene stretch film is translucent, shiny, soft. It has excellent chemical stability, heat sealability, water resistance and moisture resistance, freeze-resistant and it can be boiled. Generally low density polyethylene stretch film is made by blow molding and curtain coating. polyethylene stretch film made by curtain coating is of uniform thickness, but is rarely used because of high prices. Blow-molded polyethylene stretch film is made by PE particles blown from the blow molding machine. It is most widely used for its low cost. Stretched polyester film is using polyethylene terephthalate as raw material, It is colorless, transparent, glossy stretch film, excellent mechanical properties, high stiffness, hardness and toughness, puncture resistance, abrasion resistance, high temperature and low temperature resistance. It has good chemical resistance, oil resistance, air tightness and fragrance holding. it is one of film substrate of the commom composite stretch film that is permeability resistance. But polyester stretch film price is higher, generally having a thickness of 12μm, often used for outer materials of cooking and packaging. it prints well.

- Q: What are the requirements for geomembranes used in oil and gas storage tanks?

- The requirements for geomembranes used in oil and gas storage tanks include excellent chemical resistance to withstand exposure to various hydrocarbons and chemicals, high tensile strength to withstand the weight of the stored liquids, low permeability to prevent leakage, and durability to resist degradation from UV radiation and harsh environmental conditions. Additionally, geomembranes used in these tanks should have the ability to be welded or seamed together to form a continuous barrier and should comply with industry standards and regulations for oil and gas containment.

- Q: Are geomembranes resistant to puncture from tree roots?

- Yes, geomembranes are generally resistant to puncture from tree roots. They are designed to be highly durable and provide a barrier against external forces, including tree roots. However, it is important to note that the resistance to puncture can vary depending on the specific type and thickness of the geomembrane, as well as the size and strength of the tree roots. Proper installation techniques and regular inspection are crucial to ensuring long-term protection against root punctures.

- Q: How long can a mobile phone film use

- It depends on time you use your phone, if you play the game in a long time everyday, mobile phone film must have a short longevity. In general, a film can use two or three years. And, if you protect it well, you can use it until you do not want to use it.

- Q: Can geomembranes be used in decorative applications?

- Yes, geomembranes can be used in decorative applications. They are often used in landscaping projects to create visually appealing features such as ponds, waterfalls, or decorative garden elements. Geomembranes can be customized to mimic the appearance of natural materials like stone or rock, allowing for creative and aesthetically pleasing designs in various decorative applications.

1. Manufacturer Overview

| Location | Taian City,Shandong Province,China |

| Year Established | 2003 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, North America, Eastern Europe, South Asia, Western Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid;Geocell;Geonet and Geomat;Plastic Safety Fence);Plastics products;Rubber products;Geotextile;Carpet;Compound geomembrane |

| Product Price Range | Average |

Send your message to us

30 Mil Geomembrane Liner for Pond and Waterproof Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords