Geomembrane For Landfill

Geomembrane For Landfill Related Searches

Landfill Geomembrane Geomembrane Landfill Geomembrane Liner Landfill Geomembrane For Ponds Application Of Geomembrane Geomembranes Are Used For Geomembrane Material Geomembrane Uses Geomembrane Machine Geomembrane Applications Geomembrana Para Cisternas Waterproof Geomembrane Geomembrana Para Reservorios Geomembrane For Sale Prefabricated Geomembrane Geomembranas Para Almacenar Agua Geomembranes Plastic Geomembrane Prefabricated Geomembranes Geomembrane Containment Geomembrane Tanks Buy Geomembrane Geomembrane Waterproofing Reinforced Geomembrane Geomembrana Para Piscinas Geomembrane Systems Geomembrane Fabric Geomembrane Products Geomembrane Factory Liner GeomembraneGeomembrane For Landfill Supplier & Manufacturer from China

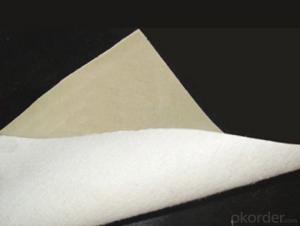

Geomembrane for Landfill is a type of high-performance synthetic liner used in various environmental and construction projects. These products are designed to provide a durable and impermeable barrier, preventing the leakage of hazardous substances and waste materials. They are made from materials such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polyvinyl chloride (PVC), ensuring excellent chemical resistance and mechanical strength.The application of geomembrane for landfill is widespread, as it is utilized in various scenarios where containment and protection are necessary. These include waste containment facilities, mining operations, water reservoirs, and industrial waste management. The geomembrane acts as a critical component in the construction of landfills, ensuring that the waste is securely contained and preventing any potential contamination of the surrounding environment. It is also used in other applications such as canal lining, pond lining, and reservoir construction, where its impermeable properties are essential for maintaining water quality and preventing seepage.

Okorder.com is a leading wholesale supplier of geomembrane for landfill, offering a vast inventory of high-quality products to cater to the diverse needs of various industries. With a commitment to providing exceptional customer service and support, Okorder.com ensures that customers receive the best possible products at competitive prices. Their extensive inventory allows for quick turnaround times and efficient delivery, making them a reliable choice for businesses in need of geomembrane for landfill solutions.

Hot Products