Lona Geomembrana Waterproof HDPE Geomembrane for Landfill to Prevent Wastewater

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

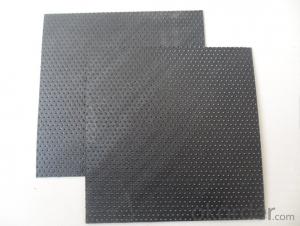

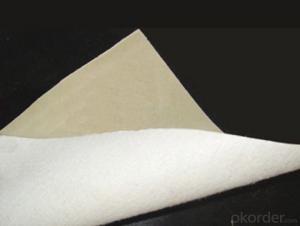

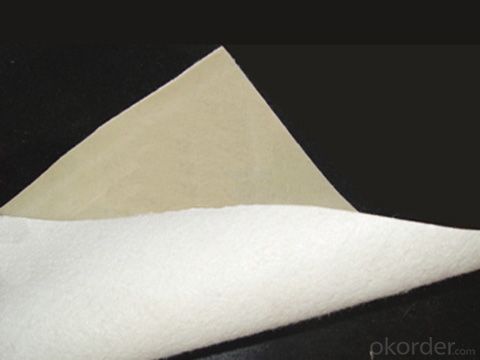

Waterproof Hdpe Geomembrane for Landfill Images

Waterproof Hdpe Geomembrane for Landfill Specification :

Thickness | Width | Length | Remark |

0.5mm | 5.8m ( Standard ) | 50m - 400m | The standard width is based on the max loading quantity according to the container size . It’s will be loading more quantity to save Freight cost .

For other types also could be produce as request , the exact package will send to you driectly . |

7.0m | 50m - 400m | ||

7.5m | 50m - 400m | ||

8.0m | 50m - 400m | ||

1.0mm | 5.8m ( Standard ) | 50m / 100m / 150m | |

7.0m | 50m / 100m / 150m | ||

7.5m | 50m / 100m / 150m | ||

8.0m | 50m / 100m / 150m | ||

1.5mm | 5.8m ( Standard ) | 50m / 100m / 140m | |

7.0m | 50m / 100m/ 140m | ||

7.5m | 50m / 100m/ 140m | ||

8.0m | 50m / 100m/ 140m | ||

2.0mm | 5.8m ( Standard ) | 50m / 100m | |

7.0m | 50m / 100m | ||

7.5n | 50m / 100m | ||

8.0m | 50m / 100m |

FAQ:

1. How about the delivery time?

Two weeks upon receipt of down payment.

2. What kind of payments do we accepted?

T/T, L/C, WesternUnion, MoneyGram.

3. What's are the MOQ?

Normally the MOQ is 5000 SQM in theory.

And we can provide you free samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee in your second order.

5. Can you produce the product according to customers' requirements?

Sure, we are professional manufacturer, OEM and ODM are both welcome

- Q: What are the limitations of geomembranes in extreme temperature conditions?

- Geomembranes have certain limitations when it comes to extreme temperature conditions. One major limitation is their susceptibility to thermal expansion and contraction, which can cause them to become brittle and potentially crack or tear. Additionally, geomembranes may experience reduced flexibility and elongation properties in extreme cold temperatures, making them less effective at accommodating ground movement or settling. In extremely hot temperatures, geomembranes can experience softening and deformation, leading to potential loss of their intended functionality. Therefore, it is crucial to carefully consider the temperature range and select an appropriate type of geomembrane for specific extreme temperature conditions.

- Q: What are the considerations for geomembrane selection in power plant ash ponds?

- The considerations for geomembrane selection in power plant ash ponds include factors such as the type and composition of the ash, the chemical and physical properties of the surrounding soil and groundwater, the expected lifespan of the pond, and the potential for puncture, tear, or abrasion. Other important considerations include UV resistance, compatibility with the ash, installation and maintenance requirements, and regulatory compliance.

- Q: What is the coated glass stick membrane?

- Coated glass can not be cleaned with abrasion cleaners. The film processed with magnetron sputtering vacuum deposition (MSVD) technology is not as strong as pyrolyzed film, and the new LOW-E film is the most sensitive.

- Q: Can geomembranes be used in irrigation canal linings?

- Yes, geomembranes can be used in irrigation canal linings. They are commonly used as liners for canals to prevent seepage and leakage of water, ensuring efficient water distribution in irrigation systems. Geomembranes, typically made of synthetic materials like HDPE or LDPE, provide a impermeable barrier that helps to conserve water and prevent contamination of soil and groundwater.

- Q: What are the safety considerations for working with geomembranes?

- When working with geomembranes, there are several safety considerations to keep in mind. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential hazards. Secondly, workers should be trained on proper handling and installation techniques to minimize the risk of accidents or injuries. This includes understanding how to safely handle and transport geomembrane rolls, as well as using proper tools and equipment for installation. Additionally, it is crucial to assess the work area for potential hazards such as uneven surfaces, sharp objects, or nearby machinery. Clearing the area of any potential dangers and ensuring proper signage and barricades are in place can help prevent accidents. Furthermore, working with geomembranes may involve the use of adhesives, solvents, or hot air guns. It is important to follow manufacturer's instructions and guidelines for the safe use of these materials, including proper ventilation and storage. Lastly, regular inspections and maintenance of equipment and tools should be carried out to ensure they are in good working condition. This can help prevent malfunctions or accidents during the installation process. Overall, prioritizing safety through proper training, the use of PPE, hazard assessments, and adherence to guidelines and protocols is essential for working with geomembranes.

- Q: What is the difference between the matte screen stick membrane and common film

- high definition film, as its name, the definition is relatively high, but it is not soiling resistance, especially in the summer it is sweating, easy dirty. Matte film is relatively good in the screen cleaner protection, but it is relatively not so clear

- Q: How do geomembranes handle settlement?

- Geomembranes are designed to handle settlement by providing a flexible and impermeable barrier between the soil and surrounding environment. They are typically installed with a sufficient amount of slack to accommodate settlement without tearing or compromising their integrity. Additionally, geomembranes can be reinforced with geotextiles or other materials to enhance their resistance to settlement. When settlement occurs, the geomembranes are able to conform to the changing soil conditions while maintaining their intended function of preventing leakage or contamination.

- Q: What are the potential risks associated with geomembranes?

- Some potential risks associated with geomembranes include punctures or tears that can compromise their effectiveness in containing liquids or gases, improper installation leading to leaks or failures, degradation over time due to exposure to UV radiation or chemical reactions, and the potential for damage during construction or maintenance activities. Additionally, if not properly managed, geomembranes can pose environmental risks if they are not disposed of or recycled correctly at the end of their lifespan.

- Q: What is the difference between the dredging of the soil and the soil pipe?

- The geotechnical membrane is made of plastic film as the impervious material, and the composite of the non-woven fabric is made of the soil anti seepage material.

- Q: How do geomembranes contribute to landfill construction?

- Geomembranes contribute to landfill construction by providing a barrier that prevents leakage and contamination of the surrounding soil and groundwater. These impermeable liners are placed at the base and sides of landfills to contain hazardous substances and prevent their migration into the environment. Additionally, geomembranes help to control the release of landfill gases, such as methane, which can be harmful to human health and the atmosphere.

Send your message to us

Lona Geomembrana Waterproof HDPE Geomembrane for Landfill to Prevent Wastewater

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords