HDPE Geomembrane for Landfill and Waterproof

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane Description

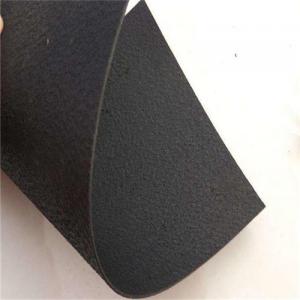

Geomembrane is made from high grade polyethylene raw material, adding carbon black, antioxidant, antiaging and UV-resistance component.

It uses the first class automatic production equipment and three-layer pressing technology. All products are in accordance with GB, GRI and ASTM test standard.

Geomembrane Specification

Thickness: 0.75mm-3.0mm

Width: 2m-12m

Color: grey, as request

Material: HDPE, LDPE, LLDPE

Type: smooth, textured

Geomembrane Property:

1) Excellent environmental stress cracking resistance property.

2) Low temperature resistance, corrosion resistance, aging resistance.

3) For service temperature range: -60℃ - +60℃.

4) Service valid term: 60 years at least.

5) Anti-crack, dimensional stability, anti-aging, smooth appearance, high friction coefficient

Geomembrane Application

1) Municipal environmental projects, water conservancy projects.

2) Landfill cap, mining heap leach pads.

3) Pond liner, canal linings, tank linings, raw water treatment reservoirs, retention ponds.

4) Waste water treatment lagoon, secondary containment.

FAQ:

1. How about the delivery time?

Two weeks upon receipt of down payment.

2. What kind of payments do we accepted?

T/T, L/C, WesternUnion, MoneyGram.

3. What's are the MOQ?

Normally the MOQ is 5000 SQM in theory.

And we can provide you free samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee in your second order.

5. Can you produce the product according to customers' requirements?

Sure, we are professional manufacturer, OEM and ODM are both welcome

- Q: Imported geomembrane anti seepage film width.

- thickness specifications, since imported geomembrane has stable chemical properties. HDPE geomembrane among imported products is of best quality, impermeable, waterproof construction is simple, low cost, wide, moisture proof,draining.

- Q: Can geomembranes be used in dam construction projects?

- Yes, geomembranes can be used in dam construction projects. Geomembranes are impermeable liners made of synthetic materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC). They are used to prevent water leakage from dams by providing a barrier between the dam structure and the surrounding soil or rock. This helps in maintaining the integrity and safety of the dam by reducing seepage and potential erosion.

- Q: Are HDPE waterproof roll, HDPE anti-seepage film and HDPE geomembrane the same?

- HDPE anti-seepage film uses resin of polyethylene. The high density polyethylene is about 2.5%. Carbon black, inhibitor, antioxygen, ultraviolet light absorber, stabilizer and other auxiliary materials are made through three-layer co-extrusion technology. HDPE geomembrane is made from 97.5% high-quality polyethylene, 2.5% carbon black, microscale antioxygen and heat stabilizer through special co-extrusion technology.

- Q: Which kind of film is preferable for bathroom?

- I do not know whether you want to stick the film on casement window or the sliding door in the bathroom. If it is the glass window, you can stick the decorative film to protect privacy. If it is the sliding door, you should stick the explosion-proof film to prevent the broken glass from harming people. 3M films of United States, CP films and films of Solar Gard all are very good. The explosion proof film is good.

- Q: Are geomembranes resistant to chemical spills?

- Yes, geomembranes are generally resistant to chemical spills. They are designed to provide a barrier against various chemicals and can withstand exposure to a wide range of substances without degrading or permeating. However, the level of resistance may vary depending on the specific type of geomembrane and the chemicals involved. It is essential to consider the compatibility of the geomembrane material with the intended chemicals to ensure optimal performance.

- Q: how to brush wallpaper basilemma

- the main processing steps of wallpaper base layer: 1, ensure the moisture content of the wall base layer should below the 8%----10%. 2, the wall before putty fumbling in a level should be firm, having no saltpetering, empty and loose. 3, after clearing the wall attachments, on the base level scrape putty 2-3 times, after abrasive?paper polished, clean the surface with gauze. 4, painted wallpaper basilemma, the wallpaper basilemma brushing the wall to dry after construction again. 5, construct on the surface of the wall which has been painted with wall paint, and you can not paste wallpaper directly on the wall, and then stripped off the original base layer putty, painted wallpaper basilemma, pasting after the paint drying.

- Q: Can geomembranes be used in contaminated site remediation?

- Yes, geomembranes can be used in contaminated site remediation. They are often used as barriers to prevent the migration of contaminants, such as oil, chemicals, or radioactive materials, into surrounding soil or water sources. Geomembranes are impermeable liners that can be installed to isolate and contain the contaminated materials, providing a protective layer and preventing further spread of the pollutants. Additionally, geomembranes can also be used in conjunction with other remediation techniques, such as soil vapor extraction or bioremediation, to enhance their effectiveness in cleaning up contaminated sites.

- Q: How do geomembranes improve water efficiency in agricultural irrigation systems?

- Geomembranes improve water efficiency in agricultural irrigation systems by acting as a barrier between the soil and the water, preventing excessive water loss through seepage or evaporation. This allows for precise control of water distribution, reducing wastage and ensuring that the water reaches the intended plants or crops more effectively. Additionally, geomembranes can also help in reducing weed growth and soil erosion, further enhancing water efficiency in agricultural irrigation systems.

- Q: What are the long-term performance characteristics of geomembranes?

- The long-term performance characteristics of geomembranes can vary depending on factors such as material type, installation quality, and environmental conditions. However, in general, geomembranes are designed to have excellent durability and resistance to various environmental stresses such as UV radiation, chemical exposure, and temperature fluctuations. When properly installed and maintained, geomembranes can provide long-term performance by effectively preventing leakage, protecting against contamination, and maintaining structural integrity.

- Q: How to deal with oil slick on fish tank?

- 1. Using the oil slick processor to make the oil slick into the filter, and then using the filtering?cotton in the filter to adsorb, at last decomposing bacteria by nitrobacterium. 2.Collect oil slick in the cup slowly and then dump it. 3. Use oil-absorbing sheet to absorb, put an oil-absorbing sheet at the opposite corner(oil-slick aggregated area) of water outlet to absorb oil slick. 4. Install trumpet funnel commingler to absorb oil slick, mix it with water, and it will be decomposed through absorption by filtering?cotton. 5. Remove contamination in the filter. 6. Feeding fish which lives on oil such as highfin coralfish or black mollyack, which can reduce the film production.

Send your message to us

HDPE Geomembrane for Landfill and Waterproof

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords