Plastic Sheet HDPE Geomembrane Suppliers for Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Plastic Sheet HDPE Geomembrane Description

Plastic Sheet HDPE Geomembrane are made from polyethylene polymer materials that blow molding,its main function is to prevent the liquid leakage and gas volatile.According to the production of raw materials can divide into HDPE geomembrane liner and EVA geomembrane liner,etc.

Main Features of Plastic Sheet HDPE Geomembrane:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

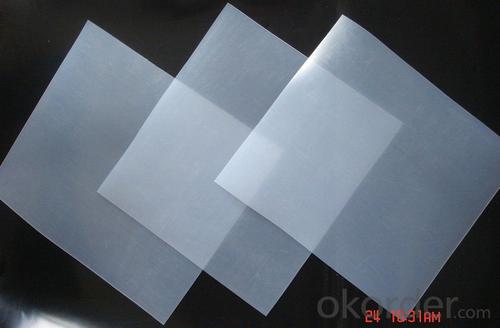

HDPlastic Sheet HDPE Geomembrane Images

Plastic Sheet HDPE Geomembrane Specification :

| Thickness | 0.12mm-4.0mm |

| Length | 50m/roll,100m/roll,150m/roll or as your choice |

| Width | 5.0m-7.0m or as your choice |

| Color | White/Black/Blue/Green,mainly black |

| Material | HDPE |

| Delivery port | Qingdao |

| Package: | woven bag or as customers' requests |

| Product time | 2-20 days |

| Features | 1.Good physical and mechanic performance |

| 2.High tearing resistance, strong deformation adaptability | |

| 3.Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance | |

| 4.Good adaptability to high and low temperature, non-toxicity, long service life | |

| 5.Good waterproof, drainage, anti-seepage and damp proof effects | |

| 6.Complete width and thickness specifications, low cost and easy installation. | |

| Note | We can do as your demand,please feel free to contact us for more information |

FAQ:

1. How about the delivery time?

Two weeks upon receipt of down payment.

2. What kind of payments do we accepted?

T/T, L/C, WesternUnion, MoneyGram.

3. What's are the MOQ?

Normally the MOQ is 5000 SQM in theory.

And we can provide you free samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee in your second order.

5. Can you produce the product according to customers' requirements?

Sure, we are professional manufacturer, OEM and ODM are both welcome

- Q: The pool with geomembrane but not long enough for what glue pool

- Should be used in geotechnical membrane professional welding, not long enough to play a role in the prevention of leakage,

- Q: where can i buy cheap geomembrane?

- Currently. Currently, good frost resistance performance,plastic film applied for seepage-proof at home and abroad, two films a cloth is in favor of the stability of protective layer and composite geo-membrane; vinyl copolymer (EVA). Corrosion resistance; and non-woven staple fiber is macromolecule staple fibre chemical material, mainly including polyvinyl chloride (PVC), polyethylene (PE), it's produced by the manufacturer according to individual requirements, low temperature resistance, various product specifications, there are many domestic geomembrane production manufacturers, ethylene & # 47 through needle stick or hot sticking forming, which is flexible material polymer chemistry, and because the rough non-woven surface, two cloth one film. Meanwhile, the base, etc., has high tensile strength and elongation, smaller proportion, strong extension, not afraid of acid, high?adaptability?to the?deformation, it can be also requested by the user according to their actual situation, and it can not only increase plastic film tensile strength and puncture resistance. The main mechanism is cutting off earth leakage passage with the imperviousness of plastic film, they have good corrosion resistance for bacteria and chemical function and has good chemical resistance, its tensile strength and elongation can withstand water pressure and adapt to dam deformation ; after it is combined with plastic film, increasing the friction coefficient of the contact surface; m2, etc., salt erosion, a cloth membrane, two cloth membrane and two cloth more and more film. Models include 200g & # 47 geomembrane takes plastic film as seepage-proof substrate, its seepage-proof performance depends on seepage-proof properties of plastic film and soil engineering impermeable material composed by non-woven cloth.

- Q: What should be paid attention to when installing electrothermal?film?

- The following items should be pain attention to during installation: 1, The installer should be professional. This is very important, some customers feel troublesome, so they find a electrician to install, and ultimately lead to many problems. Put aside technology, professional installation staff has many years of relevant experience after all. 2, The electrothermal?film will inevitably be abraded during transport, so electrothermal?film must conduct damage inspection experiments before laying, every loophole even of a small tip size will probably result in the subsequent fire. 3, Clean the ground which should has no sand when laying electrothermal?film, and can not step on it with shoes at the same time. 4, Look for specially trained electrician when wiring, securely connect and firmly fix each contact.

- Q: is the graphite electrothermal?film useful?

- Generally speaking, the effect is good. One of its advantages is that the heating is fast, easy to control, and installation is not high. However, the heating effect and the degree of thermal insulation are related to the installation of electric heating film.

- Q: What are the benefits of using geomembranes in reservoir lining?

- The benefits of using geomembranes in reservoir lining include preventing water leakage, minimizing seepage losses, protecting the quality of stored water, and ensuring long-term durability of the reservoir structure. Additionally, geomembranes provide a cost-effective solution compared to traditional lining materials and offer easy installation and maintenance. They also reduce the risk of contamination and help in managing water resources sustainably.

- Q: Is electrothermal?film heater good?

- It is safe enough, my biggest worry is the service life of floor. If the room temperature increases in a short time, heat dissipation efficiency is certainly very fast, then the temperature difference will be huge, this is the heat transfer theory.

- Q: What are the types of geomembranes?

- There are several types of geomembranes, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), ethylene propylene diene terpolymer (EPDM), and chlorosulfonated polyethylene (CSPE).

- Q: Can geomembranes be used in groundwater protection projects?

- Yes, geomembranes can be used in groundwater protection projects. Geomembranes are impermeable liners that can be used to prevent the migration of contaminants from reaching groundwater sources. They act as a barrier between the contaminated site and the groundwater, effectively protecting it from potential pollutants. This makes geomembranes a valuable tool in groundwater protection projects.

- Q: How to deal with the dust in the mobile phone film?

- If the dust particles are attached on the protective film, you also can use the scotch tape to stick it away, but you cannot blow away the dust with gas. It is possible to cause more dust particles to attach on the protective film by the use of air blowing, and the dust particles can not be blown away. Correct way of treatment is that a hand hold the film by the scotch tape, the other hand use the scotch tape to quickly stick the dust, and then you can continue to stick the film. In the process of removing the dust, you do not directly contact the inner surface of the film by your hands, otherwise it will leave oil that can not be cleaned.

- Q: Can geomembranes be used for decorative swimming pools?

- Yes, geomembranes can be used for decorative swimming pools. Geomembranes are versatile and durable materials that can be customized to create unique designs and patterns for swimming pools, enhancing their aesthetic appeal while providing a waterproof barrier.

Send your message to us

Plastic Sheet HDPE Geomembrane Suppliers for Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords