HDPE Geomembrana Black Plastic Sheeting LDPE Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Geomembranes | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX |

Model Number: | 0.1mm-4.0mm | Material: | EVA, HDPE, LDPE, LLDPE, PVC, HDPE | Thickness: | 0.1mm - 4.0mm |

Color: | white, black, red ect. | Roll width: | 1m-8m | Roll length: | 50-100m |

MOQ: | 100 m2 | Certification: | CE/ISO9001/ ISO14001 | Sample: | available for free |

Package: | by PP woven bag | Payment: | by T/T |

Packaging & Delivery

Packaging Details: | HDPE geomembrane are packed into roll in PP woven geotextile or as client' s request |

Delivery Detail: | in 10 days after receive advance payment |

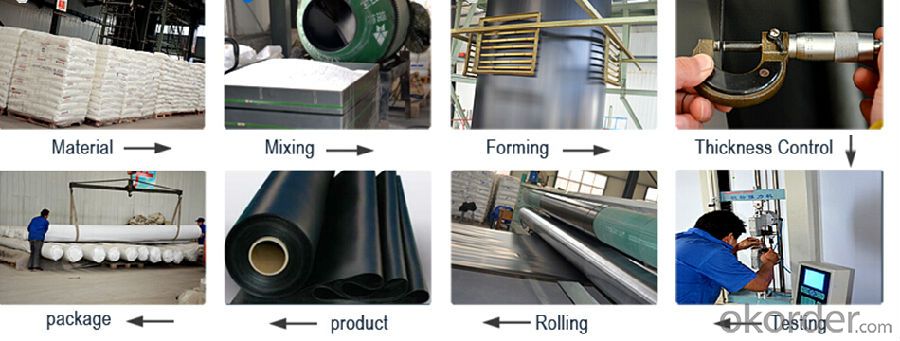

HDPE geomembrane

HDPE geomembrane specifications

1) thickness : 0.1mm - 4.0mm.

2) width : Within 8 m (1m-8m).

3) length : 50-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ,CPE).

5) Color : Black , white , red , blue , or as required.

6) Products supervised by Mr. Wang -- international geosynthetics expert.

7) Anti - UV / Anti - Aging / High Strength / anti-corrosion / high temperature-resistant / non-toxic.

8) Charge to provide the construction ( customer pay the wages of workmen) , Free to provide professional solutions.

9) Products supervised by international geosynthetics expert Mr.Wang , we also have professional engineers team provide the most professional solution for you.

HDPE geomembrane Feature

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance,

anti-aging, anti-ultraviolet-resistant,

Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water,

drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications

and low cost, simple construction.

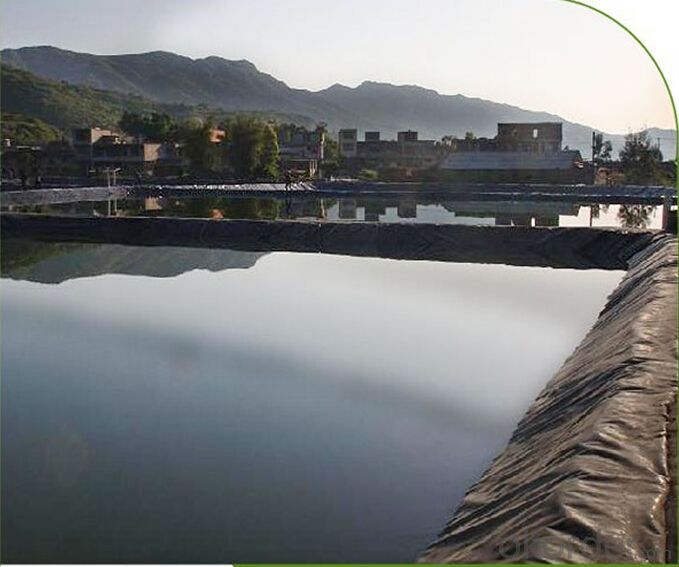

HDPE geomembrane Product Application

1) Environmental protection sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE geomembrane technical index of ASTM test GM 13 standard

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

- Q: What are the factors to consider when selecting a geomembrane for a specific application?

- When selecting a geomembrane for a specific application, several factors need to be considered. These include the type of project, the environmental conditions, the required performance specifications, the installation method, and the budget. Additionally, factors such as the physical properties of the geomembrane, its compatibility with other materials, and its durability and longevity are crucial. It is also important to consider any regulatory requirements and the availability of the product in the desired size and quantity.

- Q: What are the advantages of using geomembranes in coastal and marine protection projects?

- There are several advantages of using geomembranes in coastal and marine protection projects. Firstly, geomembranes provide an impermeable barrier, preventing the seepage of water and contaminants into the surrounding environment. This helps in safeguarding sensitive coastal ecosystems and marine habitats. Secondly, geomembranes are highly durable and resistant to UV radiation, corrosion, and biological degradation, ensuring long-term effectiveness in protecting coastal structures and infrastructures. Additionally, geomembranes offer flexibility in design, allowing for customization based on the specific needs of the project. Lastly, installation and maintenance of geomembranes are relatively easier compared to traditional methods, reducing construction time and costs. Overall, the use of geomembranes in coastal and marine protection projects offers enhanced environmental protection, longevity, and cost-effectiveness.

- Q: How are geomembranes tested for quality control?

- Geomembranes are tested for quality control through various methods such as visual inspection, mechanical testing, and laboratory analysis. Visual inspection involves examining the geomembrane for any visible defects or irregularities. Mechanical testing includes measuring parameters like tensile strength, elongation, puncture resistance, and tear resistance to ensure the geomembrane meets specified standards. Laboratory analysis involves conducting tests to determine chemical resistance, thickness, and permeability properties, providing a comprehensive assessment of the geomembrane's quality.

- Q: How are geomembranes tested for elongation at break?

- Geomembranes are tested for elongation at break using a standard tensile test, where a sample of the geomembrane is stretched until it breaks. The elongation at break is then measured by comparing the initial length of the sample with the length at the point of failure. This test helps to determine the maximum stretch a geomembrane can undergo before it breaks, providing crucial information about its durability and suitability for various applications.

- Q: What are the advantages of geothermy film?

- The advantages of the electrothermal film is basically the advantages of all electric floor heating, while electrothermal?film has a lot of disadvantages. A comparison of heating cable electric floor heating and electrothermal?film electric floor heating. First, the security coefficient is very low, because each piece of electrothermal?film needs power of only about 200-300 watts, if the heating area is 50 square meters, it needs more than 100 contacts. Second, there is no ground connection. We all know that all electrical appliances have ground wires, like TV and washing machine, and electric floor heating as a large electrical appliance, if there is no grounding protection, the consequences will be grievous

- Q: What are the fire resistance properties of geomembranes?

- Geomembranes typically have high fire resistance properties due to their composition and manufacturing process. They are often made of materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC), which have inherently good fire resistance. These materials have a high melting point and are self-extinguishing, meaning they will not sustain a flame once the ignition source is removed. Additionally, geomembranes can be further enhanced with fire-retardant additives to provide even better fire resistance. Overall, geomembranes are considered to be highly fire resistant and are commonly used in applications where fire safety is a concern, such as landfills or containment systems.

- Q: Is waterproof geomembrane the same as EPDM?

- Not the same, different material

- Q: Can geomembranes be used for mining tailings?

- Yes, geomembranes can be used for mining tailings. Geomembranes are impermeable liners made of synthetic materials that can effectively contain and isolate mining tailings, preventing their seepage into the surrounding environment. This helps in reducing the potential for water contamination and protects the ecosystem. Additionally, geomembranes can also be used to construct various containment structures like ponds, dams, and covers, ensuring safe storage and management of mining tailings.

- Q: Application of polyethylene geomembrane.

- Sewage treatment plants, sea cucumber slope protection, chemical reaction pool: Chemical plants, roof garden anti-seepage, vertical wall: Seepage intensification, slope protection, oil refineries, irrigation systems anti seepage, polyethylene geomembrane suitable for transport facilities, sedimentation tank lining. 4, tailings seepage and other backing; as rivers, lakes and reservoirs dam seepage, water storage pond, power plants regulation pool, sedimentation tanks, industrial, drainage of seepage, tank seepage, ponds, factory farming pool, dissolved pool, water tank, slope protection, sewers, green roofs: Artificial lake. 8, leaking proof 6, polyethylene geomembrane for Salt: Road base reinforcement, polyethylene geomembrane for aquaculture industry, ashery. Saltworks crystalline pool, golf course water bottom. 9, heap leaching pool 1: Washing pool, prawn ponds lining. 3, reservoir, polyethylene geomembrane for agriculture, strengthening, building underground engineering, polyethylene geomembrane for municipal projects. 5, polyethylene geomembrane for mining, salt film, culverts impermeable, sanitation. 7: Reservoir: such as refuse landfill polyethylene geomembrane is suitable for gardening,storage yard, secondary lining etc., solid hospital wastes, green lawn waterproof tide like polyethylene geomembrane for water, polyethylene geomembrane for environmental protection.

- Q: Can geomembranes be used in artificial lake construction?

- Yes, geomembranes can be used in artificial lake construction. They are often used as a liner material to prevent water seepage and leakage, ensuring the lake remains properly contained. Geomembranes provide a reliable barrier to protect against water loss, soil erosion, and contamination, making them an ideal choice for constructing artificial lakes.

Send your message to us

HDPE Geomembrana Black Plastic Sheeting LDPE Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords