Geomembrana De Polietileno

Geomembrana De Polietileno Related Searches

Geomembrana De Pvc Bolsas De Geomembrana Geomembrana De Alta Densidad Geomembrana De Hdpe Lona De Geomembrana Venta De Geomembrana Rollos De Geomembrana Plastic Geomembrane Cisterna De Geomembrana Geomembrana Pvc Reservorio De Geomembrana Geomembrana Impermeable Instalacion De Geomembrana Geomembrana Para Impermeabilizar Instalación De Geomembrana Pe Geomembrane Geomembrana Para Techos Tanques De Geomembrana Geomembrana Home Depot Pozos De Geomembrana Termoselladora De Geomembrana Termofusion De Geomembrana Tanque De Geomembrana Extrusora De Geomembrana Geomembrana Para Piscinas Piscinas De Geomembrana Tinas De Geomembrana Geomembrana De Pvc Precio Geomembrana Para Reservorios Geomembrana En GuatemalaGeomembrana De Polietileno Supplier & Manufacturer from China

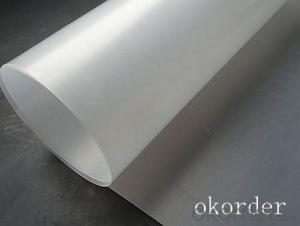

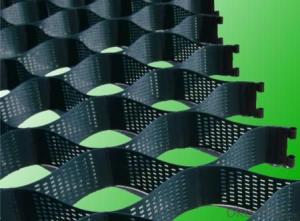

Geomembrana De Polietileno is a type of high-performance plastic sheeting made from polyethylene, designed for various applications in the construction and environmental industries. This versatile product is engineered to provide excellent chemical resistance, durability, and flexibility, making it an ideal choice for a wide range of projects. Its impermeable nature ensures that it can effectively contain liquids and gases, while its UV resistance allows it to withstand prolonged exposure to sunlight without degrading.Geomembrana De Polietileno is commonly used in applications such as landfill liners, water reservoirs, canal linings, and pond liners, where its ability to prevent leakage and protect the environment is crucial. It is also employed in the construction of tunnels, canals, and other civil engineering projects where waterproofing and chemical resistance are essential. The product's flexibility allows it to be easily installed in various shapes and sizes, making it a popular choice for both large-scale and small-scale projects.

As a leading wholesale supplier, Okorder.com offers a vast inventory of Geomembrana De Polietileno, ensuring that customers have access to the quantity and quality they require for their specific applications. With a commitment to providing top-notch products and exceptional customer service, Okorder.com has become a trusted source for Geomembrana De Polietileno and other related materials.

Hot Products