High-Density Polyethylene Geomembrane with Filter Geotextile for Waterproofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geomembrane

Classified by Material

1. HDPE Geomembrane

2. LDPE Geomembrane

3. LLDPE Geomembrane

Function: Waterproof

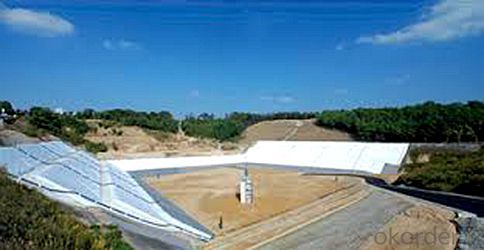

Geomembranes are the most widely used products for solid waste containment (such as landfill liners), mining, and water containment applications.

our factory uses the highest quality resins to manufacture the widest selection of high density polyethylene (HDPE) and linear low density polyethylene (LLDPE) geomembrane products available in either a black, green, white or Conductive upper surface, and in either a smooth or textured single or double-sided surface

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles aid in the reduction of liquefaction?

- Geotextiles aid in the reduction of liquefaction by providing reinforcement and stabilization to the soil. These synthetic fabrics are installed beneath the surface to improve the soil's strength and prevent its excessive movement during seismic activity. By increasing the soil's resistance to liquefaction, geotextiles help to mitigate the potential damage and hazards caused by this phenomenon.

- Q: Can geotextiles be used in geogrid reinforcement applications?

- Yes, geotextiles can be used in geogrid reinforcement applications. Geotextiles are often used in conjunction with geogrids to provide additional support and stabilization to the soil. The geotextile acts as a separation layer, preventing the intermixing of different soil layers and enhancing the overall performance of the geogrid reinforcement system.

- Q: Can geotextiles be used in shoreline revetment projects?

- Yes, geotextiles can be used in shoreline revetment projects. Geotextiles are commonly used to stabilize shorelines and prevent erosion by reinforcing the soil and providing filtration. They can be placed between the soil and the revetment materials to enhance the strength and stability of the structure while also allowing water to drain through, reducing the risk of wave damage.

- Q: Non-woven fabrics, geotextiles and geotextile geotextile

- The same material that I specialize in producing

- Q: Can geotextiles be used in railway track construction?

- Yes, geotextiles can be used in railway track construction. They provide various benefits such as soil stabilization, filtration, and drainage, helping to enhance the performance and longevity of the track. Geotextiles can help prevent the mixing of different soil layers, reduce soil erosion, and improve the track's load-bearing capacity. They are commonly used as a separation layer between the subgrade and ballast, providing additional support and stability to the track.

- Q: What are the factors to consider when designing geotextile-reinforced walls?

- When designing geotextile-reinforced walls, several factors need to be considered. 1. Soil characteristics: It is important to assess the soil properties such as its strength, permeability, and compaction. This information helps determine the appropriate geotextile material and reinforcement spacing required for stability. 2. Wall height and slope: The height and slope of the wall impact the design of the geotextile-reinforced structure. Steeper slopes may require additional reinforcement layers or geogrids for increased stability. 3. Loadings and surcharges: The anticipated loads and surcharges on the wall, such as traffic loads or nearby structures, should be considered to determine the necessary strength and stability requirements for the geotextile-reinforced wall. 4. Water and drainage: The presence of groundwater or surface water must be evaluated as it can affect the stability and durability of the wall. Proper drainage systems need to be incorporated to prevent water buildup behind the wall. 5. Environmental considerations: The potential impact of the geotextile-reinforced wall on the surrounding environment should be assessed. This includes factors like vegetation, wildlife habitats, and erosion control measures. 6. Construction methods and access: The availability of construction equipment and access to the site will influence the choice of geotextile materials and construction techniques. Considering these factors ensures the geotextile-reinforced wall is designed to withstand the required loads, maintain stability, and have long-term durability.

- Q: Geotextile was wetted by what kind of treatment

- Geotextile was originally in the project to play a reinforced, protective, filter effect. So geotextile is not afraid of water, not afraid of wet, so do not fear wet. Damped geotextile is easy to get dirty, easy to carry. Generally dried can be used, do not need to do any treatment.

- Q: What are the design considerations for geotextile-reinforced slopes?

- Some design considerations for geotextile-reinforced slopes include the slope stability analysis, soil properties and characteristics, selection of appropriate geotextile material and specifications, design of the reinforcement layout and spacing, evaluation of potential effects of water flow and drainage, and consideration of long-term performance and maintenance requirements.

- Q: Can geotextiles be used in the construction of artificial islands?

- Yes, geotextiles can be used in the construction of artificial islands. Geotextiles are commonly used in civil engineering projects for their ability to provide soil stabilization, erosion control, and drainage. In the construction of artificial islands, geotextiles can be used as a barrier to prevent soil erosion, reinforce embankments, and promote the establishment of vegetation. They can also help with filtration and separation of different materials during the island building process.

- Q: What are the limitations of geotextiles?

- Some limitations of geotextiles include their vulnerability to UV degradation, limited effectiveness in high flow conditions, and potential for clogging with fine particles. Additionally, geotextiles may not be suitable for certain applications where high strength or puncture resistance is required.

Send your message to us

High-Density Polyethylene Geomembrane with Filter Geotextile for Waterproofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords