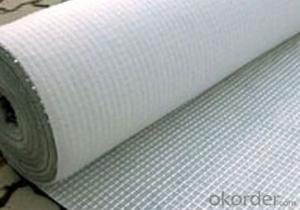

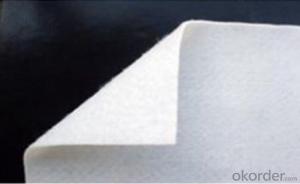

High Quality Spun-bond Geotextile fabric

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 20 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Spun-bond Geotextile fabric:

Good flexibility, permeability, filtration, separation and easy for construction.

Application of Spun-bond Geotextile fabric:

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway, highway, movement hall, Dams, hydraulic structures, hence hole, coastal shoal, reclamation, environmental protection and other projects. The main products are Synthetic staple fibers needle punched non woven geotextiles, we can produce with PET original and recylced material.

Specification of Spun-bond Geotextile fabric:

Item | Value | |||||||||

1 | Breaking strength | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

2 | Elongation at break | 40~80 | ||||||||

3 | CBR Mullen Burst Strength KN≥ | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

4 | Tear strength/KN | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 |

5 | Sieve Size O90mm | 0.05~0.20 | ||||||||

6 | Vertical Permeability Coefficient cm/s | K×(10ˉ1~10ˉ3),k=1.0~09.9 | ||||||||

7 | Thickness/mm | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

8 | Width Variation % | -0.5 | ||||||||

9 | Weight Variation % | -5 | ||||||||

- Q: Are geotextiles suitable for use in erosion control socks?

- Yes, geotextiles are suitable for use in erosion control socks. Geotextiles provide effective erosion control by preventing soil erosion and promoting sediment retention. They are designed to withstand water flow while allowing water infiltration, making them an ideal choice for erosion control socks.

- Q: Can geotext prevent rooting?

- No, geomembrane can prevent the roots to wear.

- Q: How to deal with the use of geotextiles under the roof

- Geotextile with drainage board below, the phone is the account number

- Q: Do you have a drainage board and a geotextile?

- How many dishes? Drainage board and geotextile a square need about 15 yuan cost, their trade-off

- Q: How do geotextiles contribute to pavement performance?

- Geotextiles contribute to pavement performance by providing reinforcement, filtration, and separation functions. They enhance the structural integrity of the pavement by distributing loads and reducing the potential for cracking and rutting. Geotextiles also help in preventing the mixing of different layers of pavement materials, improving drainage, and reducing the intrusion of fine particles into the pavement layers. Overall, geotextiles improve the durability, longevity, and overall performance of pavements.

- Q: Can geotextiles be used in coastal protection projects?

- Yes, geotextiles can be used in coastal protection projects. Geotextiles are permeable fabrics that can effectively control erosion and stabilize soil in coastal areas. They are commonly used to prevent sediment loss, promote vegetation growth, and provide shoreline protection against wave action. Geotextiles can be installed as a barrier or a filter to retain sediment and prevent erosion, making them a valuable tool in coastal protection projects.

- Q: How do geotextiles affect air quality?

- Geotextiles do not directly affect air quality as they are typically used in civil engineering applications for erosion control, filtration, and reinforcement purposes. However, the selection and installation of geotextiles can indirectly impact air quality by preventing soil erosion, which in turn reduces the release of dust particles into the air.

- Q: Neighborhoods: anti-seepage composite geotextile testing need to follow which test specifications, and routine testing items.

- (G / sq.m), film thickness (mm), mass per unit area deviation (%), breaking strength (KN / m), the product quality (GB / T-1998) (KN), the equivalent pore diameter O55 (mm), the vertical permeability coefficient (cm / s), the hydrostatic pressure (Mpa), the tearing strength (KN), the CBR breaking strength (KN) The And the front two said the basic almost, but hope that a detailed description can make you more clearly point.

- Q: What are the specifications for geotextiles in drainage projects?

- The specifications for geotextiles in drainage projects typically include factors such as tensile strength, permeability, durability, and UV resistance. The geotextiles should have a high tensile strength to withstand the stress and load from the surrounding soil and water. They should also have a permeable structure to allow water to pass through while preventing soil particles from clogging the drainage system. Durability is crucial to ensure a long service life, and UV resistance helps to maintain the geotextiles' performance even when exposed to sunlight.

- Q: How do geotextiles contribute to the cost-effectiveness of construction projects?

- Geotextiles contribute to the cost-effectiveness of construction projects in several ways. Firstly, they provide a cost-effective alternative to traditional construction materials by reducing the need for expensive excavation and backfilling processes. Secondly, geotextiles help to enhance the stability and durability of structures, reducing the need for costly repairs and maintenance in the long run. Additionally, they can improve the efficiency of construction projects by simplifying installation processes and reducing construction time. Overall, geotextiles offer a cost-effective solution that minimizes expenses while ensuring long-term performance and sustainability in construction projects.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2006 |

| Annual Output Value | US$ 5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Spun-bond Geotextile fabric

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 20 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords