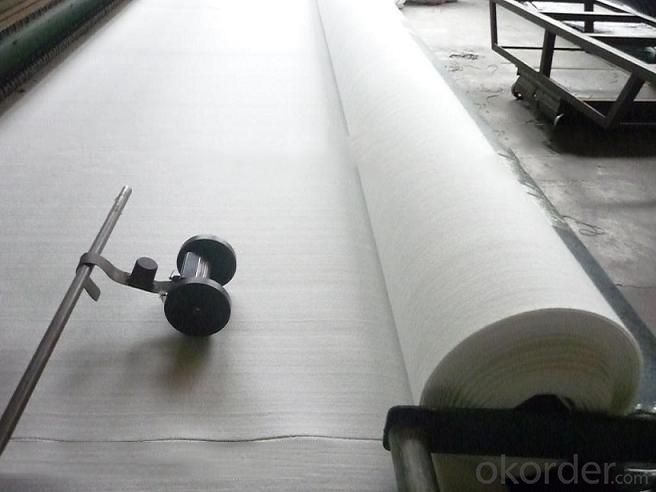

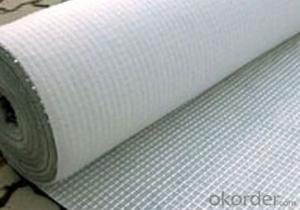

Vastag Geotextil High Quality Non-Woven Geo-Textile Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 20 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Non-woven Geotextile:

Filtration

It can be the filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different

granule pathway from the groundsill or other buildings.

Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

Protection

It prevents the bank from being washed out, protects the bank and the

bottom, prevents the water and soil from being washed away.

Specification of Non-woven Geotextile:

Material | PP(polypropylene) ,PET(polyester),PE(polyethylene) |

Technics/process | Needle punched / thermally bonded |

Specification | 100g/m2—800g/m2 |

Width | 1m—6m(as you demand) |

Length | 50-100m(as you demand) |

Colour | White, black,grey or as your request |

Packing | PE film and woven cloth width 1-6m length50-100m |

Load | According to your specification |

Payment terms | T/T, L/C, western union,paypal |

Delivery time | Within 5-7 days after your payment |

Application | Geotextiles with various indicators of quality, with good stress -strain and toughness, seepage performance and uniformiy etc., And is applicable to roads, water, rail, mining dams, rivers, airports and other civil engineering, anyone in the works played reinforcement, segregation, filtration, filtration, drainage, and then extend the project life, reduced cost and easy construction, and it is easy to ensure the quality of the project. |

Main Classification and Function of Geosynthetics

Taking a look at some of the major types and which ones can be useful for your industries. This way you will be able to figure out the ones that are more useful for you.

Geotextiles- Their main function is in the field of separation along with reinforcement, filtration and drainage. It is one of the major sources of moisture resistance. They are the best mode to increase the quality of the road when they are constructed on unstable soil. They contain synthetic fibres which are made up into flexible fabrics.

Geogrids- These are made up from grid like configuration which is used best for reinforcement.

Geo nets- They are made up from a parallel set of polymeric rib which is forming acute angles with each other. They are best for the drainage areas which transfers liquid in any type.

Geo membrane- These materials are very thin which is used for linings and landfills made up of solid waste. It will cover major areas of landfills including canals and other reservoirs.

Geo synthetic clay liners- They are used in the field of geo-environment along in containment application which may cover down the major area of transportation and other development fields like roadways and rail ways.

Acts as an Environmental friendly product

Since these products are eco-friendly biodegradable products, they are best to use for woven and non-woven fabrics. Also using these products ensures opting safe practices for the environment. Many industries seek professional help to get these materials fitted their diverse needs.

- Q: Can geotextiles be used in contaminated soil?

- Yes, geotextiles can be used in contaminated soil. Geotextiles are often used in contaminated soil remediation projects to provide separation, filtration, and reinforcement. They help to control the migration of contaminants, prevent soil erosion, and improve the stability of the soil. By effectively containing and treating the contaminants, geotextiles contribute to the overall success of soil remediation efforts.

- Q: What are geotextiles?

- Geotextiles are synthetic fabrics made from polypropylene or polyester that are used in civil engineering and construction to improve soil stability, drainage, and erosion control. They are permeable and provide strength and reinforcement to various applications such as roadways, retaining walls, and landfills.

- Q: What are the quality control measures for geotextile manufacturing?

- Quality control measures for geotextile manufacturing include conducting regular inspections throughout the production process to ensure that the geotextiles meet specified standards. This involves checking the raw materials used, monitoring the manufacturing equipment for proper functioning, and conducting tests on the finished products to assess their strength, durability, and other performance characteristics. Additionally, quality control measures may involve implementing standard operating procedures, conducting routine quality audits, and adhering to relevant industry and regulatory guidelines.

- Q: How do geotextiles help with slope stabilization?

- Geotextiles help with slope stabilization by providing reinforcement and retaining soil on slopes. They act as a barrier, preventing erosion and the movement of soil particles, while still allowing water to pass through. This helps to maintain the stability of slopes and prevents landslides or slope failures.

- Q: What are the different geotextile reinforcement techniques for slopes?

- Some of the different geotextile reinforcement techniques for slopes include the use of geotextile fabrics, geogrids, and geocells. Geotextile fabrics are commonly used to stabilize slopes by providing separation and filtration of soil particles. Geogrids, on the other hand, are high-strength materials that are used to reinforce soil and increase its stability. Geocells are three-dimensional cellular structures that can be filled with soil or other materials to create a stable slope. These techniques can be used individually or in combination to provide effective reinforcement for slopes and prevent erosion.

- Q: What are the different geotextile manufacturing processes?

- There are several different geotextile manufacturing processes, including needle punching, thermal bonding, spunbonding, and weaving. Each process has its own advantages and is used depending on the desired properties and applications of the geotextile. Needle punching involves mechanically interlocking fibers, thermal bonding uses heat to bond fibers together, spunbonding creates a nonwoven fabric through extrusion and stretching, and weaving involves interlacing yarns to create a fabric. These processes allow for the production of geotextiles with various strengths, permeabilities, and filtration capabilities, making them suitable for a wide range of civil engineering and environmental applications.

- Q: Any information on geotextiles? I am doing a mock united nation and we are representing turkey and a big issue there is erosion and we were thinking of proposing to use geotextiles and I really need to know defects of using this product, installations for this, prices, if it can be used on a big area, and if it could work for turkey. Any information will help!

- geotextile reinforcement is used to coat the ground in peatlands to make way Maintenance of a good slope stability, one needs to make the soil reinforcement (reinforcement of earth) by using geotextile Benefits of geotextile applications: Improving the design safety factor Increasing the height of the embankment Reducing the displacement embankment during construction Improve performance by increasing uniformity embankment after construction completion geotextile layer was placed on the slope during

- Q: Engineering geotextile non-woven fabrics where the cheapest can buy, where the wholesale market?

- Manufacturers need to add 8720 -

- Q: Can geotextiles be used for shoreline protection?

- Yes, geotextiles can be used for shoreline protection. They are commonly used to stabilize coastal areas and prevent erosion by acting as a barrier against wave action and water currents. Geotextiles help to retain sediment and provide structural support, making them an effective solution for shoreline protection projects.

- Q: Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2001 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001; ISO14000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Vastag Geotextil High Quality Non-Woven Geo-Textile Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 20 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords