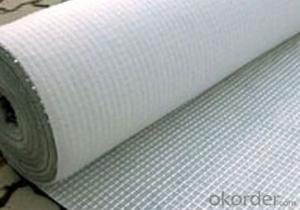

High Quality Spun-bond Geotextile

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 20 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Spun-bond Geotextile

specification:100g-800g

material:100% polyester or propylene fiber

width:3m-6m

length:50m-100m

color:as your requirements

Material | PET(polyester) |

Technics/process | Needle punched / thermally bonded |

Specification | 100g/m-1300g/m2 |

Width | 1m6m(as you demand) |

Length | 100m(as you demand) |

Colour | White, black |

Packing | PE film and woven cloth |

Load | According to your specification |

Payment terms | T/T or L/C |

Delivery time | Within 3 weeks |

Application | Geotextiles with various indicators of quality, with good stress -- strain and toughness, seepage performance and uniformity, and width, etc., And is applicable to roads, water, rail, mining dams, rivers, airports and other civil engineering, anyone in the works played reinforcement, segregation, filtration, filtration, drainage, and then extend the project life, reduced cost and easy construction, and it is easy to ensure the quality of the project. |

- Q: Heap half a month later in the mound inside dug a tree tree hole, a heavy rain, a region which has two trees in the area of water, to several days of talent, which is normal, please expert advice, More

- Are you geotextile or composite film? Is your waterproofing layer ready? Do not leak?

- Q: How do geotextiles help with sediment control in construction sites?

- Geotextiles help with sediment control in construction sites by acting as a barrier that prevents soil erosion and sediment runoff. They are placed on the ground or slopes to stabilize the soil, allowing water to permeate through while trapping sediment particles. This helps to prevent sediment from being carried away by stormwater runoff, thereby reducing the risk of water pollution and ensuring compliance with environmental regulations.

- Q: What is the geotextile of the asphalt pavement?

- You should be talking about concrete pavement and asphalt pavement with what geotextile bar, asphalt pavement dedicated filament singeing geotextile, is a way to enhance the road and roadbed of the new fine geotextile. It has high tensile strength, high elastic modulus, excellent resistance to high and low temperature performance, excellent acid resistance and aging resistance. In short, filament singeite geotextiles are widely used in asphalt pavement , Cement concrete pavement and roadbed enhancement

- Q: How do geotextiles contribute to sustainable drainage systems?

- Geotextiles contribute to sustainable drainage systems by effectively managing stormwater runoff. They act as filters, allowing water to pass through while retaining sediment and pollutants. This helps to reduce the risk of flooding, erosion, and contamination of water bodies. Additionally, geotextiles promote infiltration of water into the ground, replenishing groundwater supplies and reducing the burden on traditional drainage systems. Overall, geotextiles play a vital role in ensuring sustainable and environmentally friendly drainage systems.

- Q: What are the benefits of using geotextiles?

- Geotextiles offer several benefits, including erosion control, soil stabilization, and filtration. They prevent soil erosion by providing a protective barrier that helps retain soil particles and resist the impact of flowing water. Geotextiles also stabilize the soil by distributing loads and reducing settlement, which is especially beneficial in construction projects. Additionally, they act as filters, allowing water to pass through while preventing the migration of fine particles, improving drainage and preventing clogging. Overall, geotextiles provide cost-effective and environmentally-friendly solutions for various applications in civil engineering and construction.

- Q: Can geotextiles be used in green wall systems?

- Yes, geotextiles can be used in green wall systems. Geotextiles are often used as a filtration and separation layer between the soil and the retaining structure in green walls. They help retain moisture, prevent soil erosion, and provide stability to the system.

- Q: How do geotextiles help with soil separation in railway ballast systems?

- Geotextiles help with soil separation in railway ballast systems by preventing the mixing of different layers and ensuring the stability of the ballast. They act as a barrier between the ballast and subgrade, preventing the migration of fines from the subgrade into the ballast layer. This separation helps maintain the structural integrity of the railway track, reducing the risk of settlement and track deformations. Geotextiles also enhance drainage by allowing water to flow freely through the ballast layer, preventing waterlogging and maintaining the overall stability of the track.

- Q: What are the environmental impacts of using geotextiles?

- The use of geotextiles can have several positive environmental impacts. They help prevent soil erosion by stabilizing slopes and retaining sediment, which reduces the amount of pollutants entering water bodies. Geotextiles also promote vegetation growth by acting as a barrier against weeds and protecting newly planted seeds. Furthermore, they can be used in landfills to prevent leachate contamination and promote proper waste management. Overall, geotextiles contribute to sustainable land use and reduce the negative environmental effects associated with erosion and pollution.

- Q: How long do geotextiles typically last?

- Geotextiles typically have a lifespan of around 15 to 25 years, although it can vary depending on the specific material used, environmental conditions, and the level of stress they are subjected to.

- Q: Can geotextiles be used in the construction of artificial islands?

- Yes, geotextiles can be used in the construction of artificial islands. Geotextiles are commonly used in civil engineering projects for their ability to provide soil stabilization, erosion control, and drainage. In the construction of artificial islands, geotextiles can be used as a barrier to prevent soil erosion, reinforce embankments, and promote the establishment of vegetation. They can also help with filtration and separation of different materials during the island building process.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2006 |

| Annual Output Value | US$ 5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Spun-bond Geotextile

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 20 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords