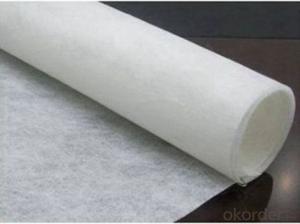

Geotextile Avant Ou Apres Tout Venant PP Woven Geotextile for Long Fibers with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Features:

Polyester filament geotextile is made by polyester textile needle consolidation , product specifications from 80-800g/m2 , it is geosynthetic application in geotechnical and civil engineering , they are arranged in three-dimensional structure of the fiber . In addition to having good mechanical properties, but also has a good aspect to the drainage performance and good elongation properties and high resistance to biological , acid , anti-aging chemical stability . Meanwhile , it also has a wide range of pore size , pore distribution tortuous , excellent permeability and filtration performance .

2. Action:

1, Water conservancy project dams and slope of filtration , channel isolation, impervious ;

2, Highways , railways, airport runways based isolation, filtration , drainage, slopes, retaining walls and pavement reinforcement, drainage ;

3, Port engineering soft ground , beach causeway , harbor piers and breakwaters reinforcement, drainage ;

4, Polyester filament geotextile has been widely used in the field of infrastructure construction , and gradually be applied to a wider range of fields.

3. Technical data:

Index | Remark | |||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

Deviation of mass per unit area % | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 | |

Thickness mm ≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 | |

Width deviation % | -0.5 | |||||||||||

Break strength kN/m | 4.5 | 7.5 | 10.5 | 12.5 | 15 | 17.5 | 20.5 | 22.5 | 25 | 30 | 40 | Vertical and horizontal |

Break elongation % | 40~80 | |||||||||||

CBR bursting strength kN ≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 | |

Equivalent aperture mm | 0.07~0.2 | |||||||||||

Vertical permeability cm/s | K*(10-4~10-3) | K=1.0~9.9 | ||||||||||

Tear strength kN≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.10 | Vertical and horizontal |

FAQ of our geotextile:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

Erosion problems have been with us since man first learned how to cultivate the land he lived in. Fortunately, many solutions have been produced since that time. One such solution is the use of woven geotextiles. Woven geotextiles are a permanent fabric to assist in the retention of soil in many different situations. Their purpose is to provide a porous foundation for separating particles of varying sizes. Another use is to allow moisture to penetrate the material, but restrict plant life from starting.

Erosion control can sometimes involve using something called a "riprap", which is when non-porous objects are used to slow down the velocity of waterflow. Common objects are large stones or concrete slabs. This reduces the chance of damaging the land. When a riprap is constructed, there are usually different particle sizes of material used. To help keep them separated and in place, woven geotextiles can be placed between the different layers. This will help control the flow of water and reduce the chance of erosion of not only the surrounding soil, but the different parts and layers of the riprap.

Woven geotextiles are used in a great deal in landscaping projects. These serve as permanent barriers against any unwanted vegetation from sprouting up in places where they are not wanted. These barriers are commonly placed three to six inches below the surface. Top soil is placed over the top and the ordimental vegetation is then planted. The woven material allows not only water to flow through it, but also provides a protective barrier to help retain the moisture during very hot and dry conditions.

On construction sites, woven geotextiles are commonly used to cover the soil after it has been disturbed by normal activities. When placed over piles of soil, these coverings make it so the piles can withstand downpours from rain and not be turned into nuisance dust by the wind. These are temporary covers that are used until the soil is ready to be used again or put back to where it came from.

Sometimes the woven geotextiles are used as a filter to assist with separating out the fine particles from the larger materials. Occasionally, the material can become clogged and needs to be replaced and the fine materials are redistributed or disposed of.

- Q: Geotextile how to sample

- It is best in the middle of a piece of cloth cut 1 square meters on the line

- Q: How do geotextiles improve the performance of railway tracks?

- Geotextiles improve the performance of railway tracks by providing a stable and durable foundation. They act as a barrier between the subgrade and the ballast, preventing the mixing of materials and reducing the risk of track settlement. Geotextiles also enhance drainage, preventing water accumulation and maintaining track stability. Additionally, they distribute load more evenly, reducing the pressure on the subgrade and minimizing the risk of track deformations. Overall, geotextiles enhance the longevity, safety, and performance of railway tracks.

- Q: Geotextile a square meter how much money

- I professional production, ranging from 3-10 yuan

- Q: Where can the general use of geotextile water can be bought

- Lingxian geotextile manufacturers, welcome to visit

- Q: Can geotextiles be used in oil and gas industry applications?

- Yes, geotextiles can be used in oil and gas industry applications. Geotextiles are commonly used for erosion control, soil stabilization, and filtration purposes in various industries, including the oil and gas industry. They can be used in applications such as pipeline construction, drilling operations, and containment systems. Geotextiles help to prevent soil erosion, provide stability for construction sites, and aid in filtration and separation of materials in oil and gas operations.

- Q: How do geotextiles affect soil moisture retention?

- Geotextiles can significantly impact soil moisture retention by acting as a barrier between the soil and the external environment. They help in reducing excessive evaporation from the soil surface, thus minimizing water loss. Additionally, geotextiles prevent the erosion of soil particles, maintaining soil structure and facilitating better water infiltration. This ultimately improves soil moisture retention by creating a more favorable and stable environment for plants to grow.

- Q: Which big god has the relevant documents? bow down!

- Mainly from the anti-seepage, to prevent the role of soil erosion, I am specializing in the production of geotextiles, wish smooth

- Q: How do geotextiles aid in the reduction of lateral spreading?

- Geotextiles aid in the reduction of lateral spreading by providing reinforcement and stabilization to the soil. When placed in the soil, geotextiles act as a barrier that prevents the movement of soil particles, thus reducing the potential for lateral spreading. Additionally, geotextiles can improve the overall strength and stability of the soil, preventing it from sliding or shifting laterally.

- Q: Can geotextiles be used for reinforcement of road embankments?

- Yes, geotextiles can be used for the reinforcement of road embankments. Geotextiles are commonly employed in road construction and maintenance to enhance the stability and durability of embankments. They provide reinforcement by distributing loads and reducing settlement, while also improving drainage and preventing erosion.

- Q: Concrete maintenance with geotextile, Tonglu how to buy

- I specialize in producing geotextile materials

1. Manufacturer Overview

| Location | Taian City,Shandong Province,China |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Oceania, North America, Western Europe, Eastern Asia |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid,Geocell,Geonet and Geomat,Plastic Safety Fence) |

| Product Price Range | Average |

Send your message to us

Geotextile Avant Ou Apres Tout Venant PP Woven Geotextile for Long Fibers with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords