Geotextile 400g Filament Spunbond Needle Punched Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

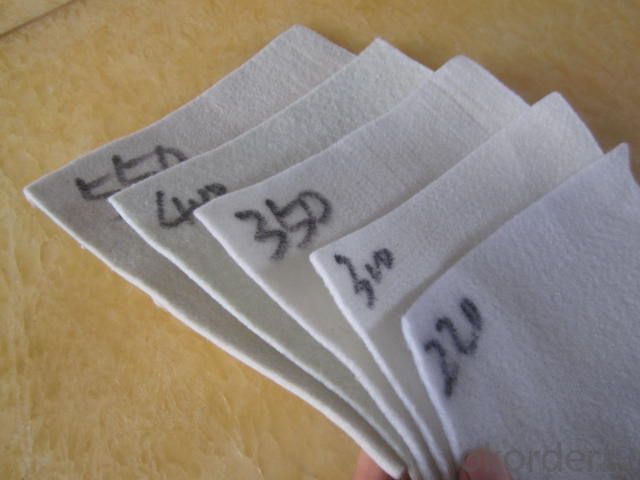

Filament needle punched nonwoven geotextile using all new polyester resin spunbonded continuous filament needle punched geotextiles are manufactured by the extrusion of fibers which are then laid down on a manufacturing "bed" and then needle punched from both top and bottom to entangle the fibers to produce a dimensionally stable geotextile.

Specification

Material | PP (polypropylene), Virgin PET(polyester), recycle PET |

Techinics | thermally bonded and needle punched |

Specification | Usually 100g/m2 to 1200g/m2 or as your demand |

Width | 1m to 6m(as you demand) |

Length | 100m(as you demand) |

Colour | White,Green,Grey,Black.etc |

Packing | PE film and woven cloth, paper core inside if you ask. |

FAQ of our geotextile:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: Production of geomembrane equipment which are such as the production of geotextile need to press machine, open charter, carding machine, etc.

- Mixing machine, screw extruder, heating die, circulating fan, traction machine, into a roll machine.

- Q: Sponge city sunken green land in the drilling drainage jacket how to set the amount of geotextile

- Need plastic blind ditch, complete specifications, collar Xiang new materials for your answer

- Q: What are the types of geotextiles used in railway subgrade

- 400 g filament geotextile, 150 / 0.3 / 150 filament geomembrane

- Q: Are geotextiles recyclable?

- Yes, geotextiles are recyclable. They can be reused or repurposed for various applications, reducing waste and promoting sustainability. However, the recyclability may vary depending on the specific type and composition of the geotextile.

- Q: Are geotextiles resistant to creep deformation?

- Yes, geotextiles are generally resistant to creep deformation. They are designed to have low deformation properties under constant or sustained loads, making them effective in preventing or minimizing creep.

- Q: Permeable geotextile how many square

- Geotextile with GB and non-standard, do not know how many grams you want, the price from a few hair to a few pieces have.

- Q: What are the different geotextile durability testing standards?

- There are several geotextile durability testing standards, including the ASTM D4355-17 for durability of geotextiles by accelerated weathering exposure, ASTM D4751-10 for determining the apparent opening size of a geotextile, ASTM D6768-18 for evaluating the effects of heat on geotextiles, and ISO 10319:2015 for determining the resistance of geotextiles to weathering.

- Q: Can geotextiles be used for filtration of contaminants in water?

- Yes, geotextiles can be used for filtration of contaminants in water. Geotextiles are permeable fabrics that can effectively filter and separate particles, including pollutants, sediment, and other contaminants, from water. They are commonly used in various applications such as wastewater treatment, stormwater management, and erosion control to improve water quality by removing harmful substances.

- Q: Waterproof and protective layer between which type of geotextile isolation layer

- Personally think to take impervious geotextile. Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Check the original post & gt; & gt; trouble to adopt, thank you!

- Q: How do geotextiles contribute to soil stabilization in mining areas?

- Geotextiles contribute to soil stabilization in mining areas by providing reinforcement and erosion control. They can be used as a barrier to separate layers of different soil types, preventing mixing and maintaining stability. Geotextiles also help in reducing soil erosion by acting as a filter, allowing water to pass through while retaining fine particles. Additionally, they enhance the load-bearing capacity of the soil, increasing its stability and preventing slope failures.

1. Manufacturer Overview

| Location | Taian City,Shandong Province,China |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Oceania, North America, Western Europe, Eastern Asia |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid,Geocell,Geonet and Geomat,Plastic Safety Fence) |

| Product Price Range | Average |

Send your message to us

Geotextile 400g Filament Spunbond Needle Punched Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords