Best, Low Price, Filament Geotextile, The Best Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

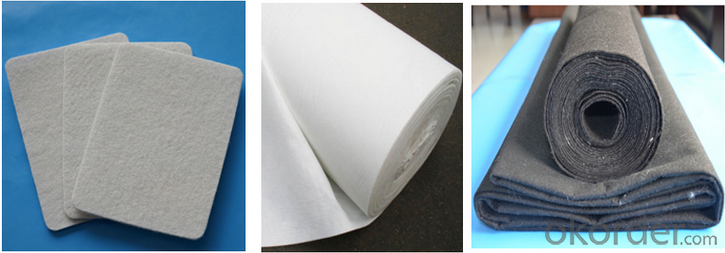

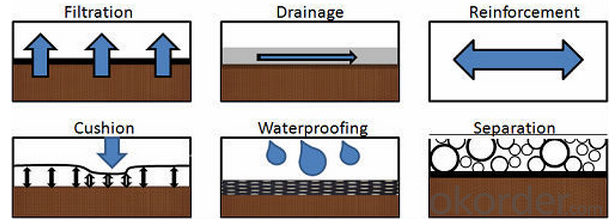

Geotextiles are permeable nonwoven fabrics used to separate,filter,reinforce, protect or drainage.Geotextiles allow filtration or separation of granular layers in roads and rail applications,used to protect membranes in landfill applications,used in coastal defence applications and used in landscaping to protect surfaces and structures from weeds and root growth.

Geotextiles are available as woven and non-woven .As liner protection, against physical damage, the non wovens are normally the answer.They are made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commonly used to separate layers like clay and drainage and to protect liner from damage.

Product Details

Features

Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction

Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

Excellent uniformity with high permeability and low pore size for soil filtration.

Supplied to a maximum width of 8.0 meters,ensuring minimum waste over large construction areas.

100% polypropylene or polyester staple fibers ,needle punched and random network formation.

UV and rot resistant and biological degradation resistant.

Majority Process

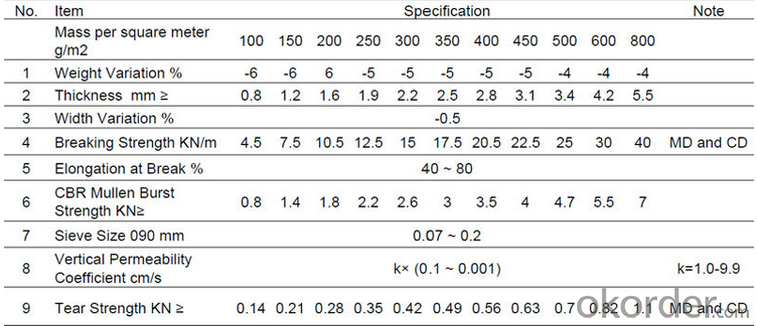

Specific Data

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please contact us without hesitate

- Q: How do geotextiles help in groundwater protection?

- Geotextiles help in groundwater protection by acting as a barrier that prevents the infiltration of pollutants into the groundwater system. They are used in various applications such as drainage systems, landfills, and erosion control, where they provide filtration and separation of soil particles, ensuring that only clean water enters the groundwater.

- Q: How to apply geotextile soil

- General geotextile cloth in the drainage layer above the geotextile covered with soil

- Q: Designers give blind ditch length of 540m, geotextile for 2835m2 more

- Too professional. You ask the manufacturers, music built

- Q: Are geotextiles cost-effective?

- Yes, geotextiles are generally considered cost-effective due to their durability, longevity, and ability to prevent soil erosion and improve stability in various construction projects. They can reduce the need for expensive excavation or drainage systems, saving both time and money. Additionally, geotextiles can enhance the performance and lifespan of infrastructure, reducing maintenance and replacement costs in the long run.

- Q: What is the effect of highway geotextile on highway construction?

- Highway geotextile is a new type of civilized artifacts in the construction of the time, laying highway geotextile can improve the carrying capacity of the road, can improve the use of the road in the process of structural damage. As the geotextile has the role of shock absorption, and has a high elasticity and resistance to deformation, so you can make the road to bear the load and stress more uniform. In the project using Hongxiang new geotextile can also improve the rigidity of the road, help to reduce road cracks.

- Q: Polyester geotextile price how much

- Is there a scientific name? Added: Will not it be filament geotext? This is what we have, but the scientific name does not call you this!

- Q: How do geotextiles improve the performance of pavements?

- Geotextiles improve the performance of pavements by providing reinforcement and stabilization to the underlying soil. They act as a barrier, preventing the mixing of different layers and reducing the potential for rutting and cracking. Additionally, geotextiles enhance drainage and filtration, allowing for better water flow and reducing the risk of moisture-related damage. Overall, their inclusion in pavement construction increases durability, extends the lifespan, and reduces maintenance costs.

- Q: What are the different factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. These include the intended application or function of the geotextile, the site conditions and soil characteristics, the required strength and durability, the installation and maintenance requirements, and the cost-effectiveness of the geotextile. Additionally, factors such as compatibility with other materials, environmental considerations, and regulatory requirements may also need to be taken into account.

- Q: Water stable health with the geotextile, sticky on the water stable, how quickly cleared

- I professional production geomembrane / geotextile, the highest cost, I wish smooth

- Q: Construction Technology of Seepage Control of Geotextile for Landscape Water System

- Laying HDPE geomembrane should try to weld at least, in ensuring the quality of the premise, as far as possible to save raw materials. But also easy to ensure quality. The lap width of the joint between the membrane and the membrane is generally not less than 10 cm, usually in the direction of the weld arrangement parallel to the maximum slope, that is, along the slope direction. Geomembrane thickness of not less than 0.25mm, too thin may produce pores, and easy to damage in the construction and reduce the anti-seepage effect. Geomembrane construction, in particular, should pay attention to laying should not be too tight, not wrinkled, stitching to be strong. Should be strictly in accordance with technical specifications construction, the good preparation, laying, splicing, inspection and backfill, such as five quality off. I specialize in production and construction

Send your message to us

Best, Low Price, Filament Geotextile, The Best Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords