Manta Geotextil Para Techos - 100g-1000g Continuous Polyester Filament Spunbond Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

1.Product Specification for 100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

Geotextile type: non-woven

Weight: 100gsm-1000gsm

Width: 1.0m-7.0m

Length: 50m-100m or as request

Color: White, black or as request

Certificates: ISO9001, ASTM, CE, SGS

2.Technical Sheet for 100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

Item | Value | ||||||||||||||||||||

Nominal Breaking strength | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | ||||||||||||

1 | Breaking strength (MD/CD)/(KN/m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |||||||||||

2 | Elongation at Break (MDD/CD) /% | 40~80 | |||||||||||||||||||

3 | CBR Mullen Burst Strength/KN | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |||||||||||

4 | Tear strength/KN | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 | |||||||||||

5 | Sieve Size O90/mm | 0.05~0.20 | |||||||||||||||||||

6 | Vertical Permeability Coefficient cm/s | K*(10-1~10-3) Among K=1.0-9.9 | |||||||||||||||||||

7 | Thickness /mm | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 | |||||||||||

8 | Width Variation % | -0.5 | |||||||||||||||||||

9 | Weight Variation % | -5 | |||||||||||||||||||

3.Application for 100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

1,Filter of embankment and slope protection of water conservancy projects, channel isolation, seepage control.

2,Isolate the basis of highway, railway, airport runway, filter, drainage, slope, retaining wall reinforcement, drainage and pavement.

3,Soft ground treatment of port engineering, beach, beach, harbor wharf and breakwater reinforcement and drainage.

4,Landfills, isolation of the ash dam, mine tailings dam in thermal power plants, the seepage control

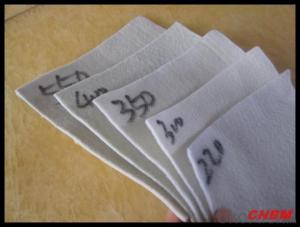

4.Product Show for 100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

5.RFQ

1) What's your payment terms?

L/C at sight, T/T are accepted

2) What's your package?

Per roll with one woven bag or as your request

3) What's your delivery time?

One week after prepayment received

- Q: Can geotextiles be used in geosynthetic reinforced walls?

- Yes, geotextiles can be used in geosynthetic reinforced walls. Geotextiles are commonly used as a separation layer between different soil types in reinforced walls to prevent soil mixing and promote proper drainage. Additionally, they can provide additional tensile strength and stability to the wall structure.

- Q: Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Q: Contracted geotextile impermeable membrane laying artificial one square how much money

- 4 yuan per square, to 5 yuan, I was a professional manufacturer

- Q: How do geotextiles affect soil consolidation?

- Geotextiles have a positive impact on soil consolidation as they provide reinforcement and stabilization. By acting as a barrier, they prevent the mixing of different soil layers, reducing the potential for settlement and increasing the overall strength of the soil. This consolidation is achieved through the interlocking of geotextile fibers with the soil particles, enhancing the load-bearing capacity and preventing the loss of fine particles.

- Q: How do geotextiles contribute to groundwater recharge projects?

- Geotextiles can contribute to groundwater recharge projects by facilitating infiltration and preventing soil erosion. These permeable fabrics are used to line recharge basins or ponds, allowing water to seep through while retaining sediment. This helps to replenish the groundwater supply by directing rainwater or runoff into the aquifer, while also protecting the underlying soil from erosion and maintaining water quality.

- Q: Can geotextiles be used in the protection of shoreline structures?

- Yes, geotextiles can be used in the protection of shoreline structures. Geotextiles are permeable fabrics that can be placed to prevent erosion and stabilize the shoreline. They can be used as a barrier between the soil and water to prevent soil loss and maintain the integrity of shoreline structures.

- Q: How do geotextiles aid in the reduction of frost heave?

- Geotextiles aid in the reduction of frost heave by providing a barrier between the soil and the freezing temperatures, which helps to prevent the migration of water and the subsequent expansion of ice within the soil. This helps to minimize the upward pressure that causes frost heave, ultimately reducing the potential damage to structures or infrastructure.

- Q: What are the different methods of installing geotextiles?

- There are several methods of installing geotextiles, including trench installation, direct placement, and mechanical installation. Trench installation involves excavating a trench and placing the geotextile in the trench before backfilling. Direct placement involves laying the geotextile directly on the ground surface and securing it with stakes or other means. Mechanical installation utilizes specialized equipment, such as a geotextile installation machine, to roll out and secure the geotextile in place.

- Q: What are the factors to consider when installing geotextiles?

- When installing geotextiles, several factors need to be considered. These include the type and quality of the geotextile material, soil conditions, site preparation, proper installation techniques, and the intended purpose of the geotextiles. It is important to assess the site's drainage requirements, load-bearing capacity, and potential for erosion. Additionally, factors like climate, anticipated traffic loads, and environmental considerations should also be taken into account to ensure the successful installation and functionality of geotextiles.

- Q: What are the advantages of using geotextiles in green roof systems?

- The advantages of using geotextiles in green roof systems include improved drainage, erosion control, and increased structural stability. Geotextiles help prevent soil erosion by allowing water to drain through while retaining the soil. They also provide a strong base for the green roof system, enhancing its structural integrity. Additionally, geotextiles can act as a filter, removing pollutants and sediments from rainwater runoff, resulting in improved water quality.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Manta Geotextil Para Techos - 100g-1000g Continuous Polyester Filament Spunbond Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords