High-Quality Waterproofing Geotextile HDPE Membrane for Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

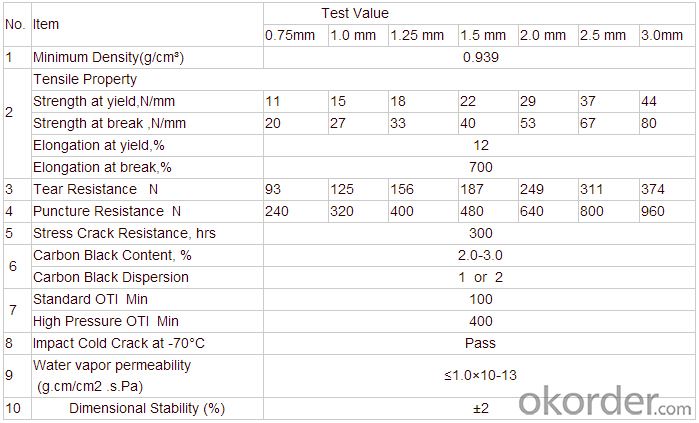

1,Specification of HDPE Geo membrane

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

2,Feature of HDPE Geo membrane

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

3, Application of HDPE Geo membrane

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

4, Technical data of HDPE Geo membrane

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: How do geotextiles help with reinforcement of embankments?

- Geotextiles help with the reinforcement of embankments by providing stability, preventing soil erosion, and improving overall durability. They act as a barrier between soil layers, distributing loads and reducing the risk of settlement or slope failure. Additionally, geotextiles allow for better drainage, reducing the buildup of water pressure behind the embankment and minimizing the possibility of landslides.

- Q: How do geotextiles contribute to groundwater protection?

- Geotextiles contribute to groundwater protection by acting as a barrier that prevents the movement of contaminants from the surface to the groundwater. They are used in various applications such as erosion control, filtration, and separation, effectively reducing the risk of pollutants reaching the groundwater and preserving its quality.

- Q: Can geotextiles be used in the protection of bridge abutments?

- Yes, geotextiles can be used in the protection of bridge abutments. Geotextiles are commonly used in civil engineering projects to provide erosion control, soil stabilization, and filtration. When applied to bridge abutments, geotextiles help to prevent soil erosion, reduce water infiltration, and enhance the overall stability and durability of the structure.

- Q: What are the key considerations for geotextile installation in high-altitude regions?

- When installing geotextiles in high-altitude regions, there are several key considerations to keep in mind. Firstly, the extreme weather conditions typically found in high-altitude areas, such as low temperatures, strong winds, and heavy snowfall, can impact the installation process. Therefore, selecting geotextiles with high durability and resistance to these conditions is crucial. Secondly, proper site preparation becomes even more important in high-altitude regions. The ground should be thoroughly assessed for its stability and potential frost heaving. Adequate measures, such as ground stabilization techniques and proper drainage systems, should be employed to ensure the long-term effectiveness of the geotextile installation. Furthermore, the selection of suitable installation methods is crucial in these regions. The use of specialized equipment and techniques, such as anchoring systems or thermal bonding, may be necessary to counteract the harsh environmental conditions and ensure proper geotextile performance. Lastly, it is essential to consider the environmental impacts of the geotextile installation in high-altitude regions. This includes adhering to local regulations and best practices to minimize disturbance to sensitive ecosystems and wildlife habitats. Overall, key considerations for geotextile installation in high-altitude regions include selecting durable materials, conducting thorough site preparation, using suitable installation methods, and addressing environmental concerns.

- Q: What is the effect of temperature on geotextile performance?

- The effect of temperature on geotextile performance can vary depending on the specific type and composition of the geotextile. In general, higher temperatures can cause geotextiles to become more flexible and pliable, which can enhance their ability to conform to irregular surfaces and provide better soil stabilization. However, extremely high temperatures can also lead to thermal degradation and loss of strength in certain geotextiles. Conversely, colder temperatures can make geotextiles stiffer and less flexible, potentially reducing their ability to perform certain functions such as filtration or separation. Therefore, it is crucial to consider the anticipated temperature conditions when selecting and designing geotextiles for specific applications.

- Q: What is the standard width of geotextile?

- 1, geotextile no standard width requirements. The geotextile width is now between 2 and 8 meters. 2, geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile.

- Q: Geotextile laying should be beyond the edge of how to set the number of specific requirements? Which specification is more detailed

- Geotextile laying should be beyond the edge of how to set the number of specific requirements? You want to understand this situation, there is no clear norms, but can refer to the "garbage sanitary landfill seepage control system engineering technical specifications" (CJJ133-2007) 5.6.6 of the provisions of not less than 300mm is possible The Article 5.6.6 of CJJ133-2007 states that: ... the repair range shall be greater than 300mm around the breakage range.

- Q: Does geotextile affect water purification?

- Do not know what you use after the purification of water, if not drinking water, I think it will not affect the water quality, the general purpose of water purification, geotextile will not affect, because the geotextile material is polyester or polypropylene, In the chemical nature of relatively stable, no changes in room temperature conditions, so there will not be any impact on water quality

- Q: 300g geotextile GB thickness is how much

- 300g geotextile GB thickness is 2mm ~ 2.5mm; geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, protective effect, with a light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance characteristics. Geotextile is one of the geosynthetics, the application of geosynthetics originated in the fifties of the twentieth century, the domestic geotextile is one of the national eight five plan, China promulgated in 1998, "geosynthetics staple fiber Acupuncture non-woven geotextile "(GB / T-1998) standard, the current geotextile has been widely used in many areas.

- Q: Can geotextiles be used for erosion control in construction sites?

- Yes, geotextiles can be used for erosion control in construction sites. They are commonly employed to stabilize slopes, prevent soil erosion, and enhance drainage. Geotextiles act as a barrier, filtering out sediment and allowing water to pass through, thereby reducing the risk of erosion and maintaining the integrity of the construction site.

Send your message to us

High-Quality Waterproofing Geotextile HDPE Membrane for Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords