Road Geotextile HDPE Geomembrane for Aquaponics Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

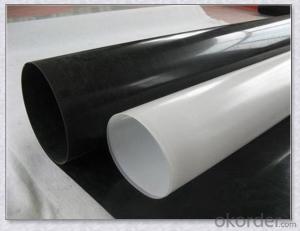

Impermeable Geomembrane HDPE for Shrimp Pond is mainly made of virgin HDPE with blow molding technique. Its main function is to prevent the liquid leakage and gas volatilization.

Application

1. Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2. Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3. Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4 .Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5. Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6 Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.)

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in green roof applications?

- Yes, geotextiles can be used in green roof applications. Geotextiles are commonly used as a protective layer between the green roof components and the underlying waterproofing membrane. They provide filtration, separation, and reinforcement functions, helping to maintain the stability and longevity of the green roof system.

- Q: Geotextile how to set quota

- There is a corresponding quota in the water transport project quota. Plus labor costs, other ancillary materials fees, machinery fees, and management fees and other fees.

- Q: What are the factors to consider when designing geotextile-reinforced walls?

- When designing geotextile-reinforced walls, several factors need to be considered. 1. Soil characteristics: It is important to assess the soil properties such as its strength, permeability, and compaction. This information helps determine the appropriate geotextile material and reinforcement spacing required for stability. 2. Wall height and slope: The height and slope of the wall impact the design of the geotextile-reinforced structure. Steeper slopes may require additional reinforcement layers or geogrids for increased stability. 3. Loadings and surcharges: The anticipated loads and surcharges on the wall, such as traffic loads or nearby structures, should be considered to determine the necessary strength and stability requirements for the geotextile-reinforced wall. 4. Water and drainage: The presence of groundwater or surface water must be evaluated as it can affect the stability and durability of the wall. Proper drainage systems need to be incorporated to prevent water buildup behind the wall. 5. Environmental considerations: The potential impact of the geotextile-reinforced wall on the surrounding environment should be assessed. This includes factors like vegetation, wildlife habitats, and erosion control measures. 6. Construction methods and access: The availability of construction equipment and access to the site will influence the choice of geotextile materials and construction techniques. Considering these factors ensures the geotextile-reinforced wall is designed to withstand the required loads, maintain stability, and have long-term durability.

- Q: Geotextile and non-woven fabrics What is the difference

- Geotextile is divided into two non-woven geotextile and woven geotextile, non-woven geotextile and acupuncture and spunlace, staple fiber and long fiber. Nonwovens means that the manufacturing process does not require weaving. Geotextiles are used for geotechnical engineering. Geotextile is part of the textile does not require the manufacture can be made, called non-woven geotextile. Non-woven fabrics can be used very broad, like we use the heart of the soft wipes, are non-woven, as well as the hotel put the shoes of the shoes, but also non-woven.

- Q: Today someone told me about a boyfriend, said to be geotextile. I wonder, geotextile cloth is what cloth? Is there there? Why is it used More

- Geotextile geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Divided into: non-woven geotextile, a textile geotextile (reinforced geotextile), warp knitted geotextile with demand can contact: Fang Lingyan Tel:

- Q: How do geotextiles prevent soil erosion on slopes?

- Geotextiles prevent soil erosion on slopes by acting as a barrier between the soil and water. They allow water to pass through while trapping soil particles, which helps to stabilize the slope and prevent erosion. Additionally, geotextiles improve soil structure by providing reinforcement and reducing the impact of rainfall, thus minimizing the potential for erosion.

- Q: What are the advantages of using geotextiles in stormwater management systems?

- Geotextiles offer several advantages in stormwater management systems. Firstly, they provide effective sediment filtration, preventing soil erosion and the accumulation of pollutants in water bodies. Secondly, they enhance soil stability by reinforcing the ground and minimizing the risk of slope failures. Additionally, geotextiles promote water infiltration and drainage, reducing the chances of flooding and ponding. They are also cost-effective as they require less maintenance and have a longer lifespan compared to traditional erosion control methods. Overall, geotextiles play a crucial role in improving the overall performance and sustainability of stormwater management systems.

- Q: Can geotextiles be trampled on the ground?

- Trampled on a long time to step on the geotextile will have an impact, geotextile main function is anti-penetration

- Q: Geotextile was wetted by what kind of treatment

- Geotextile was originally in the project to play a reinforced, protective, filter effect. So geotextile is not afraid of water, not afraid of wet, so do not fear wet. Damped geotextile is easy to get dirty, easy to carry. Generally dried can be used, do not need to do any treatment.

- Q: What are the different geotextile weight classes and their applications?

- Geotextiles are categorized into different weight classes based on their mass per unit area. These weight classes range from lightweight to heavyweight. Lightweight geotextiles, usually less than 200 grams per square meter (gsm), are commonly used in erosion control applications, such as slope stabilization and vegetation support. They provide filtration and separation functions while allowing water to pass through. Medium-weight geotextiles, typically ranging from 200 to 400 gsm, are often employed in applications like road stabilization, embankment reinforcement, and subgrade separation. They offer a balance between strength and permeability, ensuring proper drainage and preventing soil movement. Heavyweight geotextiles, exceeding 400 gsm, are primarily used in applications requiring high strength and durability. These include shoreline protection, coastal engineering, and land reclamation projects. They provide robust reinforcement and act as a barrier against erosion and wave action. The choice of geotextile weight class depends on the specific engineering requirements of the project, such as soil conditions, anticipated loads, and desired drainage characteristics.

Send your message to us

Road Geotextile HDPE Geomembrane for Aquaponics Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords