60 Mil Hdpe Geomembrane

60 Mil Hdpe Geomembrane Related Searches

Geomembrana Hdpe 40 Mils Hdpe Geomembrane Machine Geomembrane Hdpe Gse Hdpe Geomembrane Geomembrane In Hdpe Hdpe Geomembrana Wholesale Hdpe Geomembrane Reinforced Hdpe Geomembrane Hdpe Smooth Geomembrane Hdpe Geomembrane China Hdpe Geomembrane Installation Solmax Hdpe Geomembrane Geomembrana Hdpe Wholesale Geomembrane Hdpe Geomembrana Hdpe 2mm Hdpe Textured Geomembrane Geomembran Hdpe Solmax Geomembrane Hdpe Hdpe Geomembrane Specifications Hdpe Geomembrane Price Geomembrana Hdpe 1mm 40 Mil Hdpe Liner Jual Geomembrane Hdpe Hdpe Geomembrane Welding 30 Mil Pvc Geomembrane Hdpe Geomembrane Cost Hdpe Geomembrane Sheet Hdpe Membrane Wholesale Liner Hdpe Geomembrane Geomembrana De Hdpe60 Mil Hdpe Geomembrane Supplier & Manufacturer from China

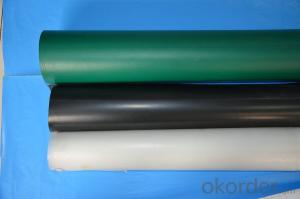

60 Mil HDPE Geomembrane is a high-quality, durable, and versatile product that is widely used in various industries for its excellent performance in preventing water seepage, providing environmental protection, and enhancing the stability of structures. Made from high-density polyethylene (HDPE), this geosynthetic material is designed to withstand harsh environmental conditions and resist chemical degradation, making it an ideal choice for applications in landfills, reservoirs, and other containment facilities.The 60 Mil HDPE Geomembrane is utilized in a broad range of applications, including water and wastewater management, mining, and agriculture. It is particularly effective in preventing the leakage of hazardous substances, thereby protecting the environment and ensuring the safety of nearby ecosystems. This product is also used in the construction of artificial lakes, ponds, and other water storage facilities, where its impermeable properties help maintain water quality and prevent contamination.

Okorder.com is a leading wholesale supplier of 60 Mil HDPE Geomembrane, offering a vast inventory of this product to cater to the diverse needs of customers across different industries. With a strong commitment to quality and customer satisfaction, Okorder.com ensures that the 60 Mil HDPE Geomembrane is available at competitive prices and is backed by exceptional service and support.

Hot Products