High-Density Waterproof Bituminous Geomembrane Roll for Seepage Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

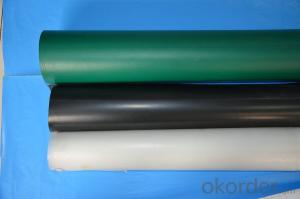

Color:Black or at your request

Density: 0.94g /cm3

Temperature range: -60oC -- +60oC

Life time: more than 50 years

Executive standard: GB/T 17643-2011

Features: Excellent environment stress resistant cracking performance and chemical erosion resistance.

Big scope of application temperature and long service life.

Applicable to river dams, tunnels, drainage bank seepage, metallurgy and chemical industry pollution prevention, construction, transportation, environmental protection works.

PE film thickness: 0.2mm-0.8mm Product Specifications: Width 4m-6m, weight 300g/m2-2400g/m2.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Is HDPE geomembrane the uppermost impermeable material used in refuse disposal plant?

- Yes, it is. It has requirement for acid and alkali resistance as well as aging resistance.

- Q: Can geomembranes be used for decorative waterfalls and fountains?

- Yes, geomembranes can be used for decorative waterfalls and fountains. They are commonly used in such applications to create a waterproof barrier and retain water in the desired area. Geomembranes provide durability and flexibility, making them suitable for designing and constructing aesthetically pleasing water features.

- Q: Can geomembranes be used in decorative koi ponds and water gardens?

- Yes, geomembranes can be used in decorative koi ponds and water gardens. They provide a reliable waterproof barrier to prevent water leakage and can be easily customized to fit the shape and size of the pond or garden. Furthermore, geomembranes offer long-lasting durability and are resistant to various environmental factors, making them an ideal choice for such applications.

- Q: How is amber membrane ?

- Amber membrane cubic American X3 thermal insulation membrane is made through America's most advanced UV control technology, which can comprehensively reflect and absorb(320I400nm) UV, to protect the skin from harmful rays so as to prevent darkening of the skin, stain, melanin cancer, at the same time protect interior decoration shiny. It is the only one full ultraviolet-proof UV400 skin protective membrane. Amber membrane cubic American X3 full ultraviolet-proof car membrane is healthy, energy-saving, thermal insulating, explosion-proof, secure, and glare reducing.

- Q: Are geomembranes suitable for use in wildlife habitat restoration projects?

- Yes, geomembranes can be suitable for use in wildlife habitat restoration projects. They can help create or restore wetlands, ponds, or other water bodies by providing effective containment and water management. Geomembranes can prevent soil erosion, control water flow, and help maintain proper water levels, which are crucial for creating and maintaining diverse and healthy wildlife habitats. Additionally, they can aid in the remediation of contaminated sites, ensuring a safe environment for wildlife. However, it is important to consider the specific project requirements and ecological considerations to determine the suitability and potential impacts of using geomembranes in wildlife habitat restoration projects.

- Q: How do geomembranes contribute to erosion control?

- Geomembranes contribute to erosion control by acting as a barrier that prevents soil and water from eroding. They are often used in construction projects, such as landfills and dams, to prevent the loss of soil particles and the erosion of slopes. The impermeable properties of geomembranes help to control water runoff and reduce the impact of erosive forces, thereby protecting the underlying soil and preventing erosion from occurring.

- Q: What is the role of the geomembrane?

- The full name of geomembrane is "high density polyethylene", with excellent property of environmental stress cracking resistance, low temperature resistance, aging resistance, corrosion resistance, larger using temperature range(-60--+60) and longer service life for 50 years. It is widely used in anti-seepage projects such as landfill of life waste,solid landfill, sewage treatment plant, artificial lake, and tailings treatment.

- Q: How to stick the film without the bubbles

- Without the bubbles: 1, to select the good quality of film, good film has wear resistance and high transparency, the rubber-faced is even without the bubbles. 2, The cell phone screen is cleaned up with clean cotton cloth which does not epilate, do not stay the dead angle. 3, when sticking the film, the phone is fixed, and then uncover the protective film of the film, but not uncover the all of the film, only a third of it. The uncovered film is aligned at the top of the mobile phone screen in the left and right, and gently put up and adjust the position. After the film is pasted, you should use the towel cloth or cell specific towel to slowly wipe from the top to the bottom in order to make it fully bind. And then, you gently uncover the 1/2 film pellicle, the next operation is same to the above until the entire process is completed.

- Q: How do geomembranes contribute to dam construction?

- Geomembranes play a crucial role in dam construction by providing an impermeable barrier to prevent water seepage. They are used as liners in the dams to ensure that water is contained and doesn't escape through the dam structure. This helps in maintaining the stability and integrity of the dam, reducing the risk of leakage and potential failure. Geomembranes also aid in protecting the surrounding environment by preventing contamination of groundwater and soil erosion.

- Q: does Landfill reservoir area include the part that is buried in the anchorage ?

- it doesn't include the area in retractable and anchoring area. the actual coverage area does not contain a linker.

Send your message to us

High-Density Waterproof Bituminous Geomembrane Roll for Seepage Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords