Geomembrana Quito Waterproof Polyethylene Film, Waterproof Geomembrane, Black HDPE Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

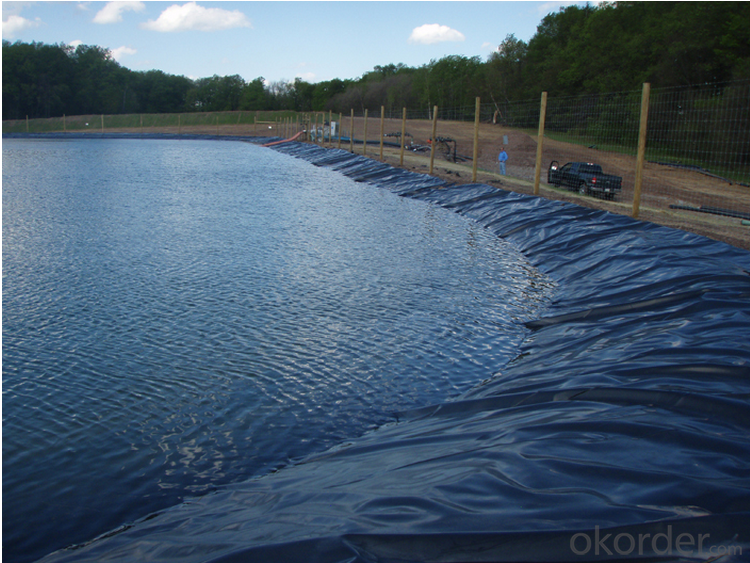

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

4. ASTM HDPE geomembrane technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: How do geomembranes contribute to erosion control in pipeline and utility corridor construction?

- Geomembranes contribute to erosion control in pipeline and utility corridor construction by providing a reliable barrier against soil erosion and water infiltration. These impermeable membranes are installed as liners or covers in areas prone to erosion, such as slopes and embankments, to prevent the loss of soil particles and the formation of gullies. By effectively containing soil and water, geomembranes help maintain the stability and integrity of the construction site, reducing the risk of damage to pipelines and utility corridors from erosion-related issues such as sedimentation or landslides.

- Q: What's the function of the base membrane of wall cloth?

- 1: Wall cloth base film is water-based with no strong taste. It is environment-friendly product in place of varnish. It can produce a hard protective film between the wallpaper and wall space, which can protect the wall space, and strengthen the water resistance of the wall bottom. It is mildew proof and antimicrobial. 2: The wall should be smooth and dry. 3: The concrete wall should be made level with putty powder. 4: For the wall space after scraped with talcum?powder is smooth, there is loose powder existent. The wallpaper should be pasted after sanding of the wall. 5: All walls in need of wallpaper pasting (concrete walls, gypsum walls, wooden fiberboard, blockboard, etc.) must first be scraped, and after they are completely dry, brush wallpaper base film on them once and until the film is dry, wallpaper pasting can be started. (If the base film is not sticky to your hand, it indicates it is appropriate to put up wallpaper at this time.)

- Q: What are the requirements for geomembranes used in desalination plants?

- Geomembranes used in desalination plants need to meet certain requirements to ensure their effectiveness and longevity. These requirements include being resistant to chemicals and high salt concentrations, having low permeability to prevent water leakage, being durable and able to withstand harsh environmental conditions, and being flexible to accommodate various shapes and sizes of water storage and treatment facilities.Additionally, they should have excellent strength and tear resistance to withstand installation and ongoing operational stresses. Overall, the key requirements for geomembranes in desalination plants are chemical resistance, low permeability, durability, flexibility, and strength.

- Q: What are the advantages of using geomembranes in radioactive waste disposal?

- The advantages of using geomembranes in radioactive waste disposal include their ability to provide a barrier against the migration of radioactive materials, their durability and resistance to degradation, their flexibility to conform to different terrains, their cost-effectiveness compared to alternative containment options, and their compatibility with other engineered barrier systems. Additionally, geomembranes can be easily inspected and repaired, enhancing the overall safety and efficiency of radioactive waste disposal.

- Q: How do geomembranes perform in high humidity gas containment applications?

- Geomembranes perform well in high humidity gas containment applications. They are designed to be impermeable and resistant to moisture, making them effective barriers against gas leaks. The high humidity does not affect their performance or integrity, ensuring reliable containment of gases even in such conditions.

- Q: What is a coated glass?

- Coated glass is coated one or more layers of metal, alloy or metal compound thin film on the surface of the glass so as to change the optical properties of the glass and meet certain requirements. It is mainly used in construction, automotive, decoration and other fields.

- Q: Does computer screen need to stick film?

- Whether it is or not can not be generalized, which should depend on individual demand. View from the visual effect, there are mainly two kinds of computer screen films at present: One is high-definition film, with which the screen turns to be more delicate. But it will increase the light reflection, which will lead to visual disturbance when used in high-lighted environment. The other is anti-reflective dull polished film, which is visually not very delicate, but enable people clearly see the screen in bright environment. So people with visual improvement needs can choose the corresponding film. From the perspective of screen protection, computer film has certain abrasion-resistant hardness, which has physical protective effect on the screen. So it is recommended to stick film for computers used in dusty environment or whose screen is often wiped .

- Q: Are geomembranes resistant to root penetration?

- Yes, geomembranes are generally resistant to root penetration. They are designed to provide a barrier and protect against the infiltration of roots, preventing any potential damage to underlying structures or containment systems.

- Q: What is the HDPE geomembrane of rough surface?

- The rough surface HDPE geomembrane material is composed of 97.5% high-quality polyethylene, 2.5% carbon black, trace antioxidant and heat stabilizer. The rough surface is the result of a special co-extrusion process, the process is a molding production, the most important characteristic rough surface HDPE geomembrane offer is that it can increase the stability of the slope material, from Ji-light delay Gan hoot imitation dec containing wet splashing and ultimately HDPE geomembrane can carry Kongyong Rong maximize product adapted to the characteristics of the laying of a steep slope in cost savings but also improve design capabilities.

- Q: How to choose glossy and matte geomembrane used in refuse landfill ?

- Hope it is easy to understand because it is not complicated at all. Actually, the dfference between matte and glossy membrane is the coarse surface, which is to increase friction. I f it is for refuse landfill, there are mainly three parts needed geomembrane for seepage-proof. reservoir bottom, side slope and cover (or closure). For "reservior bottom" , pave a layer of imported glossy geomembrane at the bottom of the landfill for horizontal seepage prevention. For side slope, use matte geomembrane around the landfill to increase friction because the side slope has vertical angle, that is, to make the geomembrane hung on the side slope. For cover or enclosure, use glossy membrane for horizontal seepage prevention to prevent rain pouring into the reservior and percolate increasing and isolate the garbage in landfill from the outside. It may not be comprehensive, but from practical experience coorperated with Canada Solmax Inc. Hope it's helpful.

Send your message to us

Geomembrana Quito Waterproof Polyethylene Film, Waterproof Geomembrane, Black HDPE Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords