HDPE Geomembrane Black or White for Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

HDPE geomembrane are made from High density polyethylene polymer by bolw film process .

Have Smooth surface , Textured surface , Anti-Skid suface

HDPE Geomembrane Main Function

Antiseepage and seperation

Geomembrane Property

1. Good flexibility

2. For service temperature range : -70℃ ~ +110℃

3. Corrosion resistance , aging resistance

4. Excellent environmental stress cracking resistance property

5. High tensile strength and elongation

HDPE Geomembrane Usage

Landfills , sewage or waste treatment seeage .

River bank , lake dam , dam , water dam and reservoir, channel , has liquid pool ( pit , mine )

Metro , basements and tunnels , tunnel seepage control lining Foundation and other foundation saline seepage

Embankment , upstream impervious blanket level , foundation vertical impermeable layer , cofferdam construction , waste disposal

Sea water , fresh water fish farm

Road , highway , railway foundation expansive soil and loess of the waterproof layer

Roof impervious

HDPE Geomembrane Specification

No. | Item | Test Value | |||||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | |||||

1 | Minimum Density(g/cm³) | 0.939 | |||||||||

2 | Tensile Property | ||||||||||

Yield Strength ,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||||

Break Strength ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | ||||

Yield Elongation ,% | 12 | ||||||||||

Break Elongation ,% | 700 | ||||||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | |||

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | |||

5 | Stress Crack Resistance, hrs | 300 | |||||||||

6

| Carbon Black | ||||||||||

Carbon Black Content, % | 2.0-3.0 | ||||||||||

Carbon Black Dispersion | Carbon black dispersion(only near spherical agglomerates) for 10 different views 9 in categories 1 or 2 and 1 in category 3 | ||||||||||

7

| Oxidative induction time(OIT) | ||||||||||

Standard OTI Min | 100 | ||||||||||

High Pressure OTI Min | 400 | ||||||||||

8 | Oven aging at 85℃ | ||||||||||

Standard OIT-% retained after 90 days | 55 | ||||||||||

High pressure OIT-% retained after 90 days | 80 | ||||||||||

9 | UV Resistance | ||||||||||

Standard OIT retained after 1600 hrs | 50 | ||||||||||

High pressure OIT retained after 1600 hrs | 50 | ||||||||||

10 | Low tempreture impact brittle property at -70°C | Pass | |||||||||

11 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | |||||||||

12 | Dimensional Stability (%) | ±2 | |||||||||

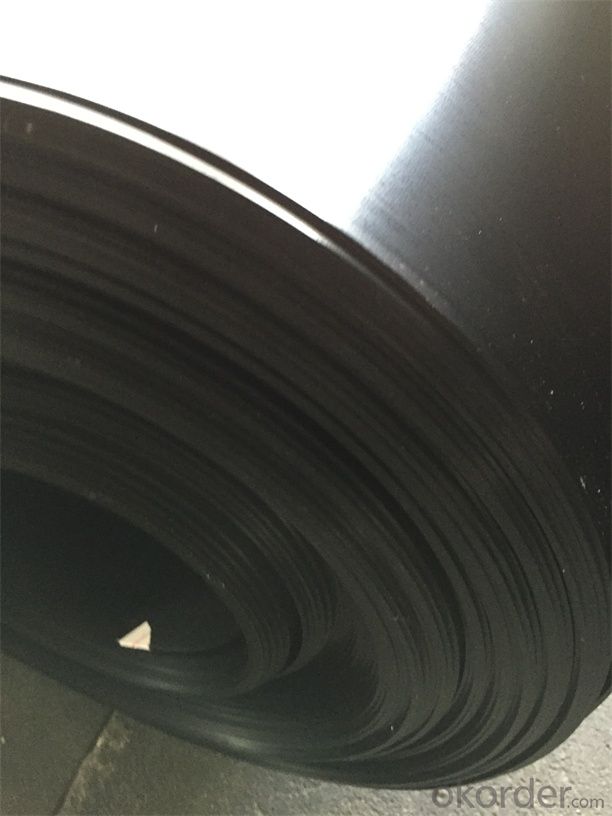

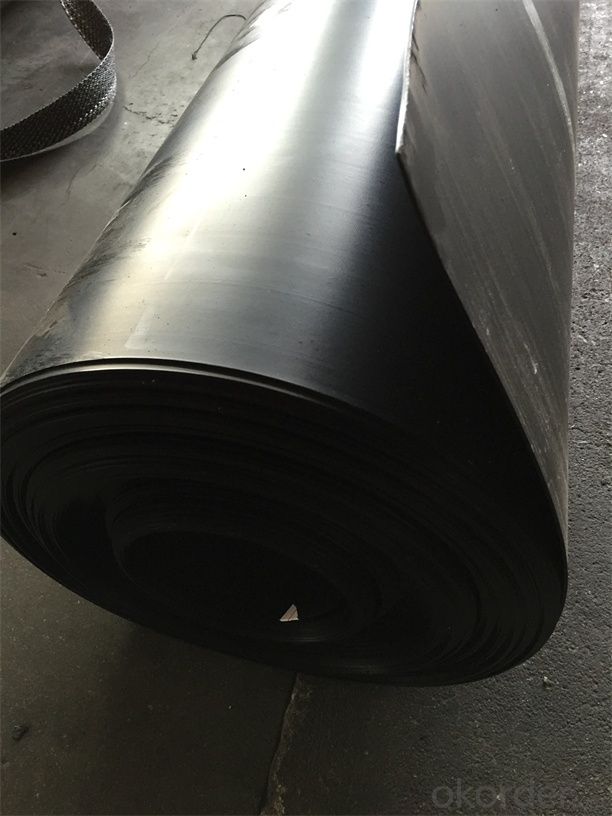

Gemembrane Show:

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q:What are the characteristics of HDPE geomembrane?

- As a new material, geomembrane has excellent anti-seepage effect, corrosion resistance and chemical stability. And it can process features and functionality according to the actual project needs. Geomembrane has been widely used in water conservancy embankment dam , reservoir seepage. At the same time, it has ben widely used as seepage-proof, anti-corrosion, leakage-proof and non-hygroscopic material in channel, impounding reservoir, cesspit, swimming pool, house building, underground structure, wasteyard, environmental engineering, etc.

- Q:how to remove the oxidation of the packaging film of aluminium alloy door and window by the sunlight?

- Try using a solution of diluted paint, as well as alcohol and acetone solution (because they are all organic solvents). But I think that the kind of diluted paint would be easy to use. Here we call it releasing the receiving water, it may also be called lacquer thinner.

- Q:Is electrothermal membrane electric heating blanket useful?

- Electrothermal film heating kang is easy to use, the electrothermal film heating system differs from dot mode heating system represented by radiator, air conditioning, heating radiator system, line heating systems represented by heating cable, and LC supply heating high-tech products developed by modern aerospace flight technology.

- Q:What is the difference between HDPE geomembrane and LDPE geomembrane?

- LDPE is softer. HDPE is high density polyethylene while LDPE is low density polyethylene. HDPE is harder while LDPE is softer. And LLDPE, also known as linear low density polyethylene, is much softer. HDPE and LLDPE can be used as manufacturing materials of impermeable geomembrane.

- Q:How is amber membrane ?

- Amber membrane cubic American X3 thermal insulation membrane is made through America's most advanced UV control technology, which can comprehensively reflect and absorb(320I400nm) UV, to protect the skin from harmful rays so as to prevent darkening of the skin, stain, melanin cancer, at the same time protect interior decoration shiny. It is the only one full ultraviolet-proof UV400 skin protective membrane. Amber membrane cubic American X3 full ultraviolet-proof car membrane is healthy, energy-saving, thermal insulating, explosion-proof, secure, and glare reducing.

- Q:Characteristics of geomembrane

- Therefore, the service life period of composite geomembrane is sufficient to meet the service life period of the dam seepage-proof requirement., Ethylene / vinyl acetate copolymer (EVA), mainly including polyvinyl chloride (PVC) .hiphotos.2m added stabilizer polyethylene film, whose years of working is 30 to 40 years under sewage conditions, with small proportion, low temperature resistance, corrosion resistance, good extensibility. Composite geomembrane is a kind of soil engineering impermeable material taking plastic film as a substrate, and combined with non-woven fabrics. The service life period of geomembrane, good anti-frost?property.

- Q:How do geomembranes handle ground subsidence?

- Geomembranes are designed to handle ground subsidence by providing a protective barrier between the ground and any structures or materials above it. They are typically made of strong, flexible materials that can withstand the movement and settling of the ground without tearing or compromising their integrity. Additionally, geomembranes can be installed with proper anchoring and tensioning techniques to minimize the impact of ground subsidence on the liner. Overall, geomembranes act as a reliable and durable containment solution that can effectively handle ground subsidence.

- Q:Is it good to use wall decoration film when decorating the house?

- In terms of environmental protection, compared to other interior decoration materials, side effects of wallpaper on human health are the minimal. However, as a raw material, the wallpaper is a single product. It should not be forgotten that varnish and wall paper adhesive are painted before the wall paper is laid. At that time, form of the wallpaper has changed a lot. After the wallpaper is paste up, the adhesive is covered behins the wallpaper, making the formaldehyde difficult to volatile, so the release cycle of formaldehyde in wall paper is relatively longer than in wall paint. Wall paint also contains formaldehyde, but construction procedures are relatively fewer than that of wallpaper. In comparison, after the latex?paint is brushed, the formaldehydewill be bascially volatile in three days and have no smell left after 15 days.But another type of pollution, mercury and lead, existed in wall paint.After the walls are painted, some children will touch them with the hand or are used to sucking their fingers. In this way, mercury and lead in paint will have an impact on the their body. Europe and other developed countries also considered the paint as the best choice for interior decoration as early as forties and fifties, but the paint is barely used now.It is seen from the above that both wallpaper and wall paint have their own environmental problems.So, on the one hand I do not recommend you to lay wallpaper all over the house; on the other hand, we also have good reason to choose wallpaper as the effect it creats can not be reached by wall paint.

- Q:How do geomembranes contribute to erosion control in airport runway and taxiway construction?

- Geomembranes contribute to erosion control in airport runway and taxiway construction by providing a protective barrier against water infiltration. These impermeable membranes prevent water from seeping into the runway and taxiway subgrades, reducing the potential for erosion caused by water flow. Additionally, geomembranes help to stabilize the underlying soil, improving its load-bearing capacity and resistance to erosion.

- Q:How do geomembranes contribute to erosion control on slopes?

- Geomembranes contribute to erosion control on slopes by providing a barrier that prevents the erosion of soil and the loss of sediment. They effectively reduce water infiltration, control surface runoff, and enhance soil stabilization. Additionally, geomembranes can help alleviate the impact of heavy rainfall, storms, and other factors that may lead to erosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Geomembrane Black or White for Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords