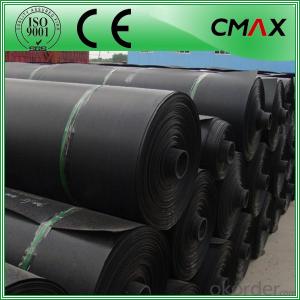

Hdpe Geomembrane Welding

Hdpe Geomembrane Welding Related Searches

Geomembrane For Landfill Geomembrane In Hdpe Geomembrane In Pakistan Pvc Geomembrane Liner Pvc Geomembrane Institute Hdpe Geomembrane Machine Basics Of Structural Engineering Hdpe Geomembrane Sheet Waterproof Geomembrane Geomembrane MaterialHot Searches

Geomembrane For Sale China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Price Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Wholesale Hdpe Geomembrana Wholesale Liner Geomembrane Geomembrane Liner Supplier Wholesale Geomembrane China Pvc GeomembraneHdpe Geomembrane Welding Supplier & Manufacturer from China

Okorder.com is a professional Hdpe Geomembrane Welding supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Hdpe Geomembrane Welding firm in China.Hot Products

FAQ

- What's the difference between recycled plastic bucket and plastic bucket made of raw material?

- The easiest way to do this is to press hard, see flexibility and bounce back. You can also cut off a small piece with a knife, lost in the water, can float is generally the new material is recycled sink. If PE is the plastic bucket, the recycled material is usually porcelain white, and the raw material should be translucent.

- What plastic material has great impact resistance?

- The ability of metal materials, machinery parts and components to resist impact damage is called impact strength.

- Is the plastic with high melting index good?

- The melt index, the full melt flow index, or the melt flow index, is a numerical value that indicates the fluidity of the plastic material when it is processed.

- What kind of material is the plastic bag commonly used in supermarkets now?

- 1. HDPE is a shopping bag for supermarkets. It feels cool and hard to use. Do not add color, the bag is very dim.2. low density polyethylene, used for packaged food, feels soft and transparent.

- What is plastic film material?

- The material is plastic particles. Polyethylene film is used for polyethylene particles; polypropylene film is polypropylene particles. Some of the films are blown out of film blowing machines; some are cast films and pressed out of the machine.

- What are the specific differences between plastics and plastics?

- Plastic has good insulation for electricity, heat and sound: electrical insulation, arc resistance, heat preservation, sound insulation, sound absorption, vibration absorption, noise elimination, and outstanding performance.

- What is the material of plastic flat screen?

- Plastic flat net (also known as plastic breeding net) is plastic material in the extruder heating melting through the extrusion into a special rotating head is provided with a plurality of holes inside and outside of the die, the molten plastic flowing through the die pore forming two shares melt silk, because of head rotation, two shares converge to a continuous filament thus, the formation of network, after cooling into the net.

- How to test plastic raw materials?

- Sample appearance quality. The plastic raw material is produced according to the normal production process, and the appearance quality of 10~20 parts is observed. The sample product shall not be cracked, deformed, foamed, broken, expanded or shrunk, and other defects that affect appearance. Smooth surface and clear surface.