Termite-repellent and Rodent-repellent Nylon Jacket Compound for cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nylon compound:

1. Competitive price

2. Customized products

3. Stable quality

4. 30 years of experience

Nylon compound:

1. Applications of Nylon compound:

Used for power cable with large size, owning well performance of resistance to brittleness.

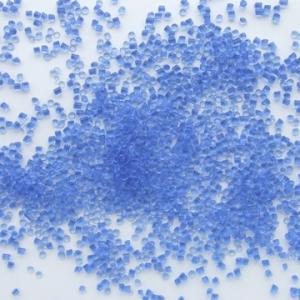

2. Description of Nylon compound:

This nylon jacket compound, based on PA6 resin, is produced and pelletized by special technology with adding special modifier, anti-oxidant and other special additives. It has advantages of processing easily, low temperature resistance, cracking resistance, and smooth surface, termite-repellent and rodent-repellent.

3. Processing of Nylon compound:

The compound can be processed with conventional extruders. The L/D should be greater than or equal to 25; and the compression ratio of screw should be greater than 1:2.5.

Drying: be dried at 85-100°C for 3-7 hours before use.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die | |

PA1001-D | temperature °C | 230 | 240 | 245 | 245 | 240 | 235 |

PA1001-A | temperature °C | 230 | 240 | 245 | 245 | 245 | 245 |

PA1001-S | temperature °C | 230 | 245 | 245 | 250 | 250 | 255 |

Note: The above temperature is recommended only, and the actual processing temperature should be according to the type of machine and environment.

4. Storage and transport of Nylon compound:

Packaging:25kg/bag,Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. Properties of Nylon compound:

Item | Unit | PA1001-A | PA1001-D | PA1001-S |

Standard | Standard | Standard | ||

Density | g/cm3 | 1.14 | 1.12 | 1.14±0.01 |

Hardness | ≥Shore D | 68 | 68 | 65 |

Tensile Strength | ≥MPa | 60 | 50 | 50 |

Elongation at Break | ≥% | 160 | 160 | 50 |

Notched Impact Strength | ≥KJ/m2 | 20 | 20 | 6 |

Volume Resistivity | ≥% | 1.0×1012 | 1.0×1012 | 1.0×1011 |

Dielectric strength | ≥MV/m | 24 | 24 | 24 |

Oxygen Index |

| — | — | — |

Melting point | °C | — | — | -- |

Heat distortion temperature | °C | — | — | -- |

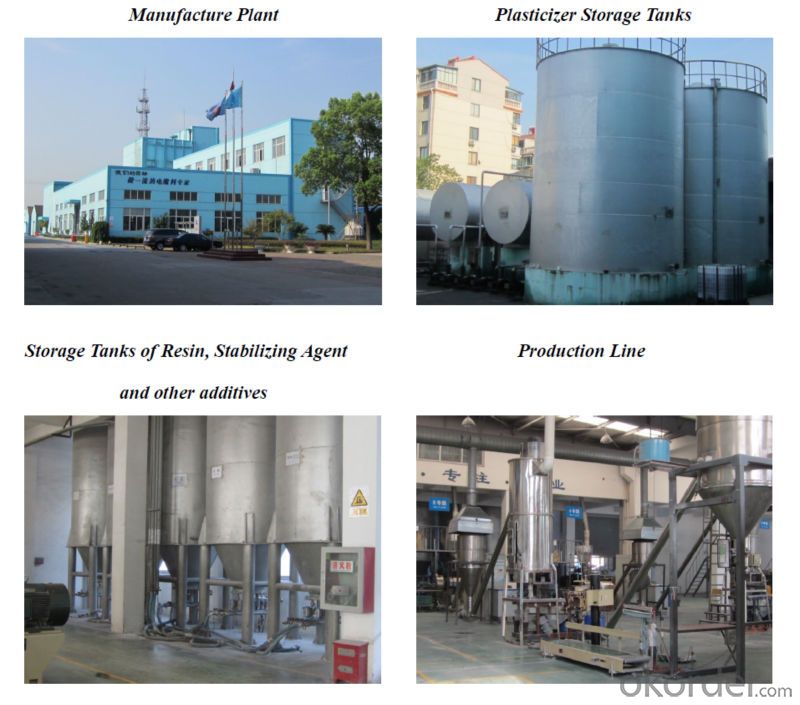

6. Company

- Q: What plastic material has great impact resistance?

- The ability of metal materials, machinery parts and components to resist impact damage is called impact strength.

- Q: What are the common raw materials used in plastic bottles? What are the main features?

- PP bottles are non-toxic, transparent, and have certain heat resistance and impact resistance. They are generally loaded with fruit juice and shampoo. They can be hot filled (very important for fruit juice drinks). They can not be sterilized by pressure cookers, and their transparency is poor.

- Q: What material is the disc made of, metal or plastic?

- The compact disk is the carrier of functional structures (such as grooves, etc.), and its material is polycarbonate (PC), which has excellent impact toughness, large temperature range, good dimensional stability, weatherability and non toxicity.

- Q: What's the difference between recycled plastic bucket and plastic bucket made of raw material?

- Recycled materials produce more plastic impurities, so they look rougher and darker in color. If the stock is ready, the color is better. Recycled materials are very poisonous. If they are packed with food, it's best not to use them

- Q: What is the essential difference between plastic raw materials and engineering plastics?

- Plastics can be divided into two major categories: General Plastics and engineering plastics. They are usually granular or powder in order to be easy to process before they are madeGeneral plastics refer to common plastics with large output, wide use, good formability and low price. Such as PVC, polyethylene, polypropylene, polystyrene and so on. Products made of plastic film, pipe, woven bags and plastic daily necessities. The yield and consumption of general-purpose plastics account for more than 80% of all plastics.Engineering plastics refer to plastics that meet the needs of industrial parts. Relatively speaking, they yield large, wide range of applications. Mainly ABS, polycarbonate, nylon, POM, modified polyphenylene ether, thermoplastic polyester and so on. Products have TV casing, plastic gears, optical materials, gaskets and so on.There is also a special engineering plastics, in addition to its characteristics of engineering plastics, its comprehensive performance is higher, long-term use temperature above 150 degrees celsius. It also has special functions and special uses. Mainly used in high-tech industries, such as atomic energy, rockets, satellites, aerospace, automotive, electronic and sports equipment, and other structural materials. Commonly used special engineering plastics are fluorine plastic, silicon resin, polyimide, peek, liquid crystal polymer and so on.

- Q: What is the ash content of PP plastic raw materials?

- PP if a few raw materials mixed with ash, and the color of raw material and color, it is PP powder, the water can not be dissolved. Try, if it is more, and the color is white, it is talcum powder or toner, water or dissolved or muddy water

- Q: What is the specific material for plastic pallets?

- With excellent mechanical properties, its strength and elasticity are higher than HDPE, and it has good flexural fatigue resistance. It has good heat resistance and good chemical stability. Besides being concentrated by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. The high frequency insulation performance of polypropylene is excellent because of its almost no water absorption, so the insulation performance is not affected by temperature.

- Q: What is plastic film material?

- Plastic film material is plastic micelle, which is made by petrochemical enterprises from petroleum refining.

- Q: What kind of raw material is plastic hollow board made of?

- Hollow plate can be divided into anti-static hollow board, hollow conductive plate, ordinary hollow board three categories, anti-static hollow board is mainly used in electronic components on the packing, in order to avoid contact with other charged objects, causing parts for electric spark friction. Anti static hollow board is a new kind of plastic hollow board packing material. Antistatic hollow board mainly replaces ideal environmental protection material, such as corrugated board, wood board and metal plate.

- Q: What are the bulk density, size and moisture content of the general plastic material?

- The bulk density has something to do with particle size. The larger the particle, the smaller the bulk density of the same composition. This is because the accumulation of material quality, material bulk density = space volume. The bulk density is pseudo density.

Send your message to us

Termite-repellent and Rodent-repellent Nylon Jacket Compound for cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords