Halogen Free FT2 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

plastic granules:

FT2 flame retardant Halogen-free TPE cable compound

plastic granules: 1, Type and application: USB wires, telecommunication cables, charger wires and HDMI wires

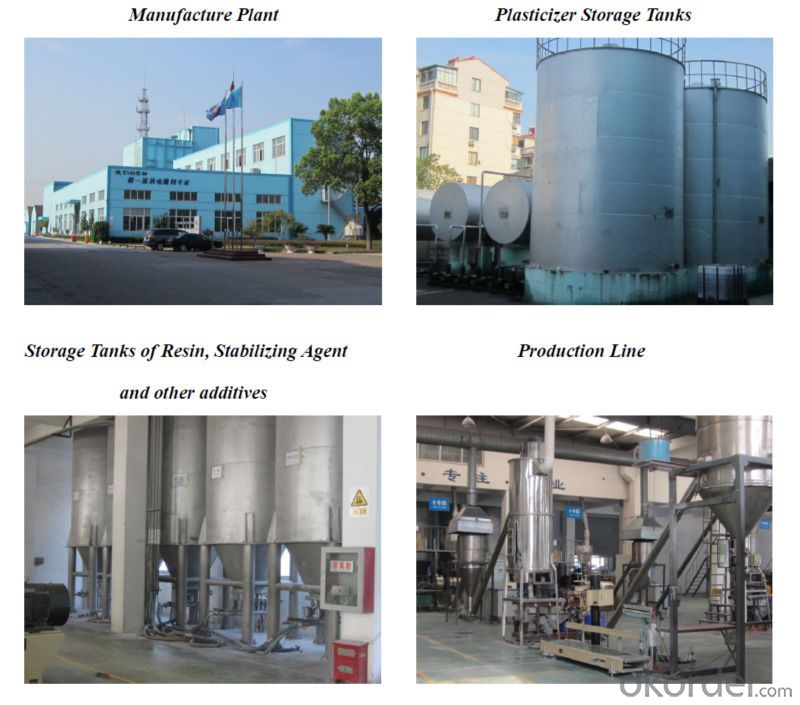

2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has been stored more than two months. 4, Storage and transport Packaging:20kg/bag,PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: 6,Company Pictures

|

- Q: What material is best for plastic gears?

- At present, the demand for plastic gear with high wear resistance and noiseless gear is very strong. POLYMSJ noiseless nylon composite occupies a leading position in this field. If it doesn't solve the problem, you can try it out.

- Q: Commonly used plastic products, which are made of what raw materials, which can be recycled, I hope to get a professional answer in detail

- In daily life, we can directly contact or perceived plastic, is the most common plastics routine, mainly include five categories: PE (polyethylene), PP (polypropylene), ABS (acrylonitrile butadiene styrene plastic), PVC (polyvinyl chloride), PS (polystyrene), these five categories accounted for plastics the vast majority of plastic raw materials used, the basic can be classified as special plastic varieties, such as: PPS (PPS), PPO (polyphenylene ether), PA (polyamide), PC (polycarbonate), POM (POM), they are in daily life in the small amount of the product, mainly used in industry and engineering the national defense science and technology and other high-end fields, such as automotive, aerospace, construction, communications and other fields.

- Q: How is plastic material made out?

- Some plastics are made up of synthetic resins, with or without additives such as plexiglass and polystyrene. The so-called plastic, in fact, it is a kind of synthetic resin, the shape of the natural resin with pine resin similar, but also because of the chemical strength of the synthesis, and is called plastic.

- Q: Is the tableware made of PP raw material the best of those plastic tableware?

- 1 polyethylene terephthalate (PET) is made up of ethylene. Used as mineral water bottles, cola beverage bottles, fruit juice bottles, etc.. Because it can only heat 120 degrees, so only suitable for cold and warm drink, if installed high temperature liquid or heating deformation.2. High density polyethylene (HDPE), suitable for food and medicine bottles, cleaning supplies and bath products, shopping bags, garbage cans.3. Polyvinyl chloride (PVC) is polymerized from vinyl chloride. High temperature and contact with grease, PVC easily release phthalate two formic acid and incompletely polymerized toxic vinyl chloride monomer. PVC film made of PVC, transparent, difficult to break, strong adhesion, low prices, we see in the supermarket, supermarkets on the box firmly glued to the film is it. According to its characteristics, it is only suitable for vegetables and fruits refrigerated preservation, it is not appropriate to put meat, cakes and other foods containing more fat, it should not be used as microwave heating

- Q: What are the raw materials needed for producing plastic hair dryer shell and flashlight shell?

- The shell materials are ABS and PAABS material is acrylonitrile (Acrylonitrile), 1, 3- (Butadiene) and styrene butadiene (Styrene) three kinds of graft copolymer monomer, ABS plastic molding temperature is 180-250 DEG C, but preferably not more than 240 DEG C, the resin will be decomposed.

- Q: Does anyone know what kind of plastic material PP-M40 is?

- High gloss PP has high gloss, high fluidity, heat resistance, medium impact toughness and fine processability. The utility model is suitable for making household appliances (rice cookers, vacuum cleaners, electric irons, etc.), office equipment, instruments and meters, beauty equipment, etc..

- Q: How about the price of plastic raw materials now?

- The downstream continues to be on demand, with little change in demand. There is a more detailed analysis of quotations

- Q: What's the shell of the relay? What exactly is plastic?

- Relays, usually thermosetting plastics, refer to plastics that can be cured or otherwise insoluble in heat or other conditions, such as phenolics, epoxy plastics, etc.. Thermosetting plastics can be divided into two types: formaldehyde, cross-linking and other cross-linking. Formaldehyde crosslinked plastics include phenolic plastics and amino plastics (such as urea formaldehyde melamine formaldehyde etc.). Other crosslinked plastics include unsaturated polyester, epoxy resin, phthalic two, diallyl resin, etc..

- Q: What are the plastic raw materials for this purpose?

- From the bathroom supplies we use when we wake up, the tableware we use for breakfast, the stationery we use for work and study, the seat cushion for sleeping, the mattress, and the shell of TV set, washing machine and computer

- Q: Is plastic raw material rubber?

- The difference between the plastic and the rubber is plastic or not, but because of thermosetting plastics, this definition is not comprehensive. Another difference is whether the elastic body, but because of the appearance of thermoplastic elastomer, this definition is not comprehensive. In general, rigid high molecular material thermoplastic processing, sure is a plastic elastomer; and thermosetting rubber must be classified. The more ambiguous reference history. Silicone rubber and polyurethane is thermosetting elastomer rubber, is, but completely different from natural rubber. There is a part of polyurethane is thermosetting plastics, even thermoplastics, composition, structure and it depends on the characters.

Send your message to us

Halogen Free FT2 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords