Halogen Free VW-1 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

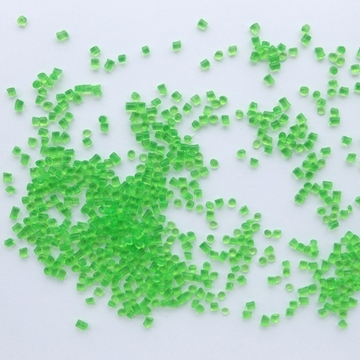

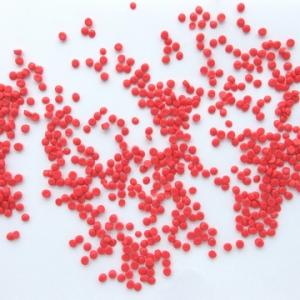

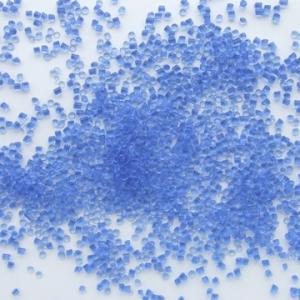

plastic granules:

VW-1 Flame Retardant Halogen Free TPE Cable Compound

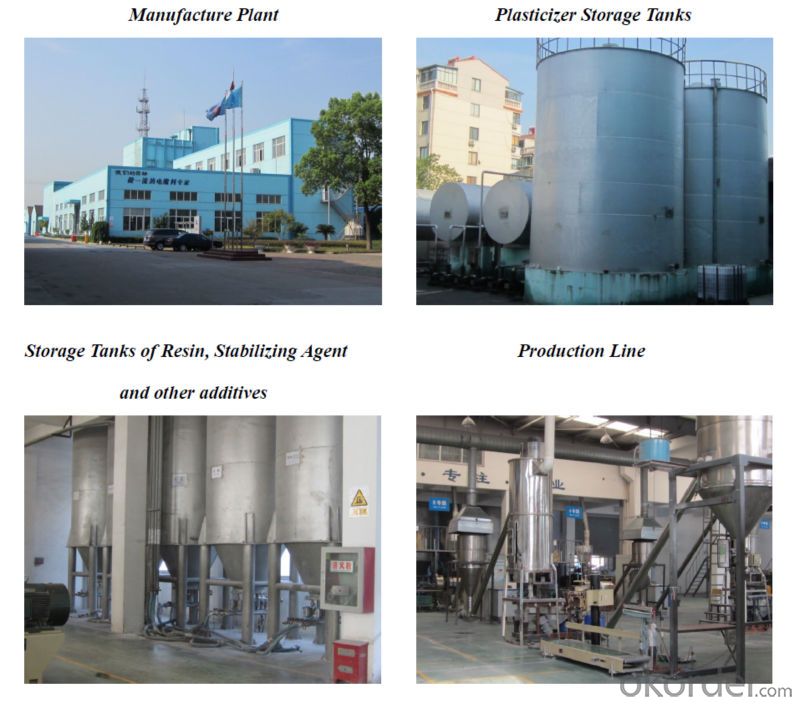

plastic granules: 1, Type and application: Used for USB data cable, HDMI high-frequency cable and communication cable 2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has storage time exceeding one months. 4, Storage and transport Packaging:20kg/bag,Aluminum foil and PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: ItemUnitTypicalE3675AE3680AE3685AEC3685ES3685E3688AE3690AE3656DDensityg/cm31.05±0.031.05±0.031.07±0.031.08±0.031.11±0.031.06±0.031.14±0.031.10±0.03HardnessShore A75±380±385±385±385±388±390±397±3230°C×5kgMelt Indexg/10min2.42.51.11.81.21.21.10.8Tensile StrengthMPa10.512151111141222Elongation at Break%350310290230210260250210Thermal aging°C*h121°C*168hTS retention≥75%9599101999810196104EB retention≥75%7980798282858078Hot deformation°C*h150°C*1hVariation≤50%--3612272726174Oxygen indexO2 %2526272725272626Impact BrittlenessTemperature-60 °CPassPassPassPassPassPassPassPassVolume Resistivity,at 20°C ≥1×1014Ω m3.9×10144.6×10145.1×10143.2×10143.6×10145.3×10144.7×10145.1×10146,Company Pictures

|

- Q: Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- The blowing ratio is one of the control points of blown film production and! Refers to the ratio between the bubble diameter and the diameter of not blowing blowing after.

- Q: Is the plastic with high melting index good?

- It was established by the American Society for measurement standards (ASTM), a method used to identify plastic properties, according to the DuPont Co (DuPont).

- Q: What kind of material is the raw material of plastic pipes?

- The raw material of plastic pipe is mainly based on the plastic tube type, type, polyethylene plastic pipe (PE) is the raw material of ethylene, polyvinyl chloride (PVC) material is polyvinyl chloride, polypropylene pipe (PB) is the raw material propylene.

- Q: What are the POE plastic raw materials?

- Poe plastic raw materials are polymers of ethylene and butene, polymers of ethylene and isobutene.

- Q: What is the material of plastic dip?

- Also known as alias dip coated, hot dip coating, hot compress. Dip (plastic) is a kind of plastic coating process. According to the different raw materials used in dipping, they can be divided into liquid dipping (coating) and powder dipping (coating).

- Q: What raw material produces the plastic to the human body not to harm, to the environment does not have the pollution?

- Starch plastics containing starch in more than 90%, add other components also can be completely degraded, there are Japan Sumitomo Business Corporation, American Wamer-Lamber company, Italy Ferrizz company claims of success starchier in 90% to 100% of full starch plastics, in (January ~ 1) completely biodegradable without leaving any trace, no pollution, can be used in the manufacture of various containers, bottles, films and garbage bags etc. all starch plastics production principle is that the starch molecular allostent anddisorderly change formed with thermoplastic starch resin, also known as the thermoplastic starch plastics. The molding process can be used in traditional plastic processing equipment. With starch as the potential advantages of development of bio degradable plastics raw materials: starch has biodegradability completely in various environments; plastic in the degradation of starch molecules or after ashing, the formation of two oxygen Carbon gas, without soil or air poison; take appropriate technology to make starch thermoplastic after mechanical properties can reach for manufacturing plastic material; starch is a renewable resource, inexhaustible, pioneering starch utilization is conducive to rural economic development. That is, starch plastics production in China of vast the majority of starch filled plastics, is added in a certain proportion of polymer materials in non biodegradable starch, resulting in the collapse of material physical property through biodegradation of starch, prompted a large number of end groups that exposed to oxidative degradation, but the rest of the "collapse" after the PE, PVC and so on are not always possible degradation the residue in soil, of course, days and months multiplying will cause pollution, so the foreign ownership for such products will be eliminated.

- Q: What are the raw materials for environmental friendly portable plastic bags?

- [environmental protection portable plastic bags] generally speaking, there is no fully environmentally-friendly plastic bags, only some plastic bags to add some ingredients, it is easy to degrade some. Biodegradable plastic. The main material is low pressure polyethylene plastic, in the production of plastic packaging products to add a certain amount of additives, such as starch, modified starch or other cellulose, photosensitizer, biodegradable agent.

- Q: What are the raw materials needed for making plastic bags?

- The bags made of two materials each have their own characteristics, and are chosen according to the purpose and performance of the products. Polyethylene is petrochemical products, prices vary according to crude oil and market conditions every day, at present LDPE (high pressure polyethylene) offer at 13500 yuan. HDPE (low pressure polyethylene) at 11000 yuan up and down.

- Q: How to test plastic raw materials?

- Sample appearance quality. The plastic raw material is produced according to the normal production process, and the appearance quality of 10~20 parts is observed. The sample product shall not be cracked, deformed, foamed, broken, expanded or shrunk, and other defects that affect appearance. Smooth surface and clear surface.

- Q: What is the raw material for producing high temperature polyethylene plastic bags?

- High density polyethylene (HIGH DENSITY, POLYETHYLENE, HDPE) commonly known as low-pressure polyethylene, compared with LDPE and LLDPE, with high temperature resistance, oil resistance, vapor permeability and resistance to environmental stress cracking resistance, and electrical insulation and shock resistance and cold resistance is very good, mainly used in blow molding, injection molding etc..

Send your message to us

Halogen Free VW-1 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords